RogerS

Established Member

In another thread, I talked about how I went about getting some custom spindle moulder cutters made. But I cocked up. Can you see where ? PM me if you can.

To recap

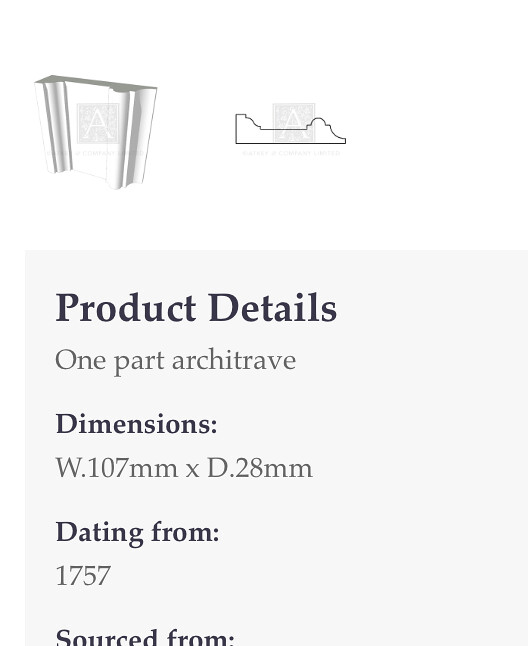

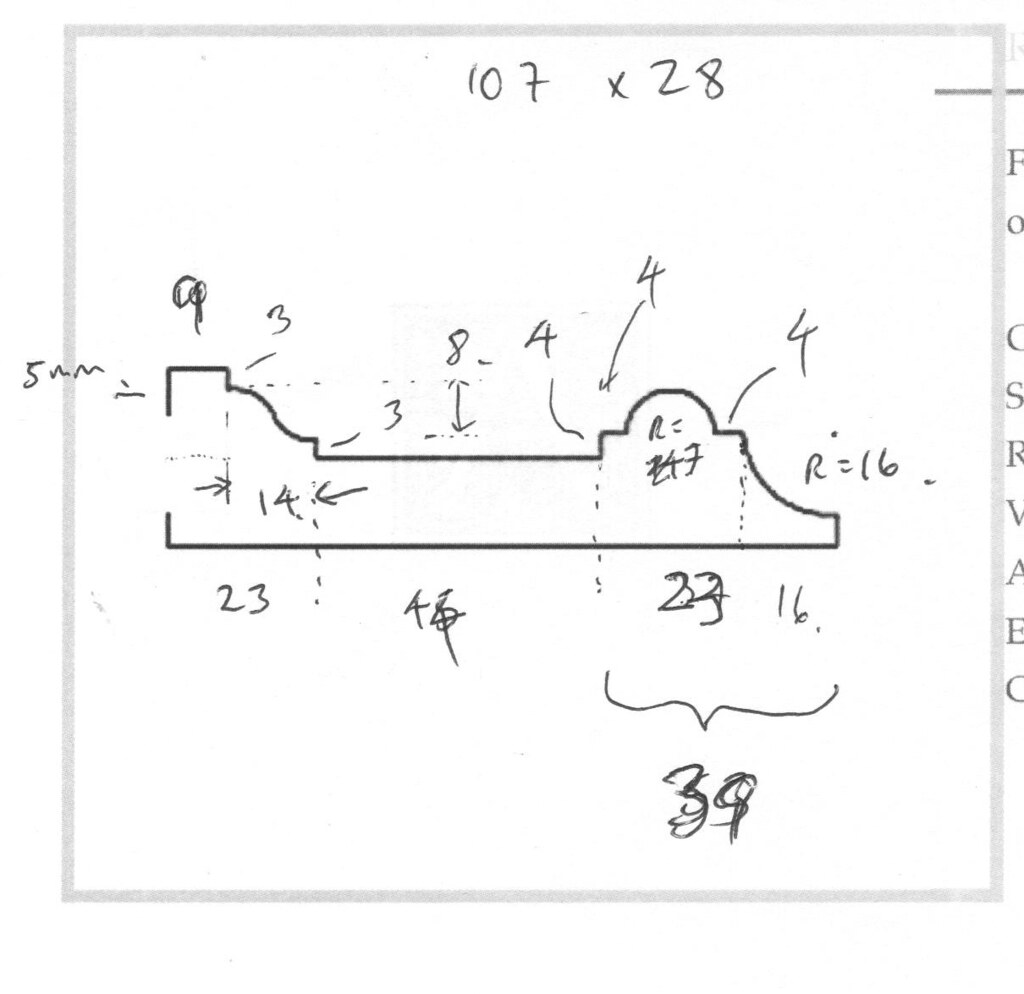

This is the architrave I wished to make

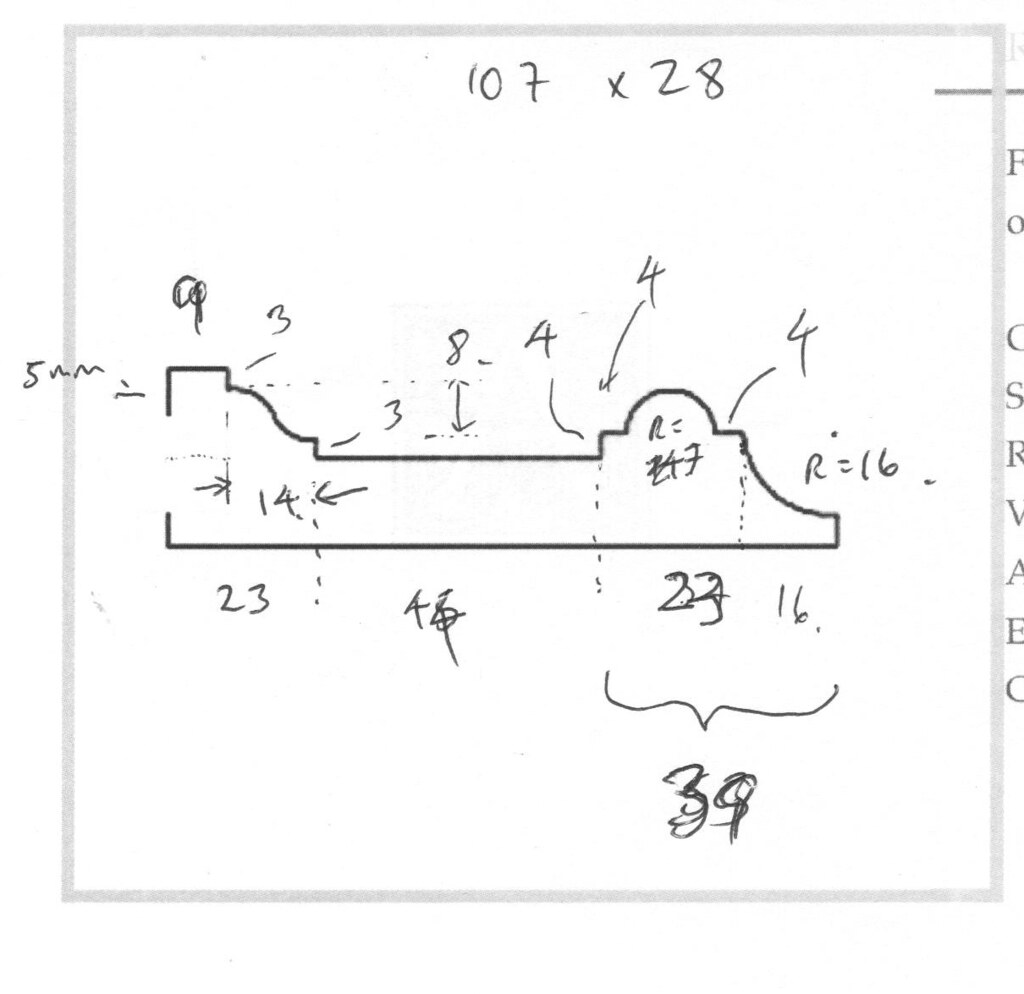

My working drawing

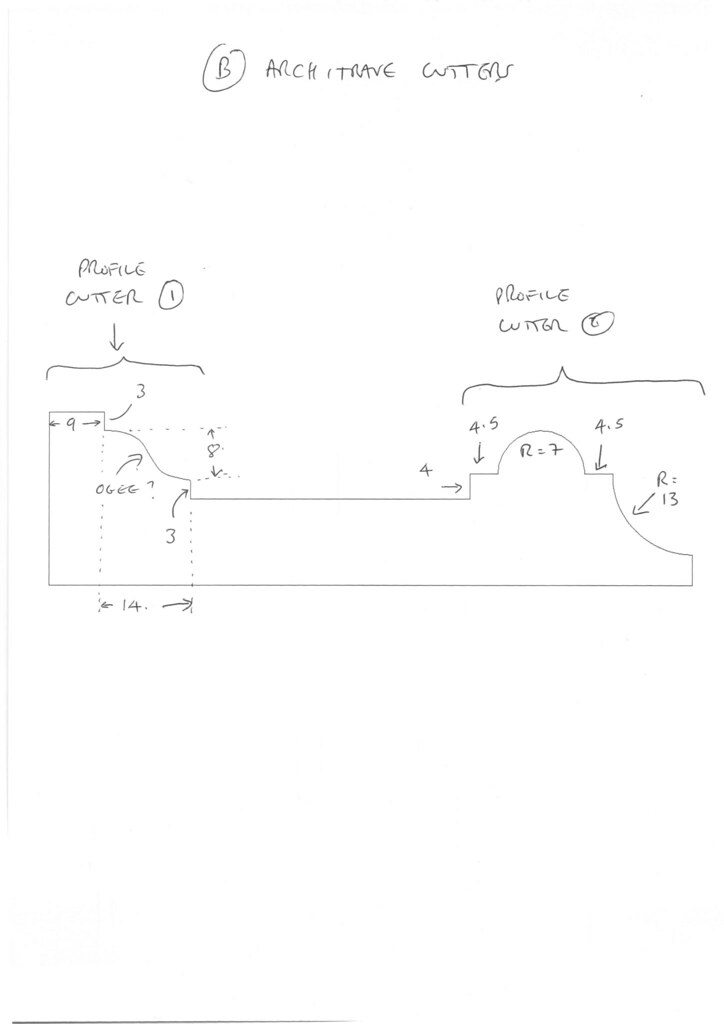

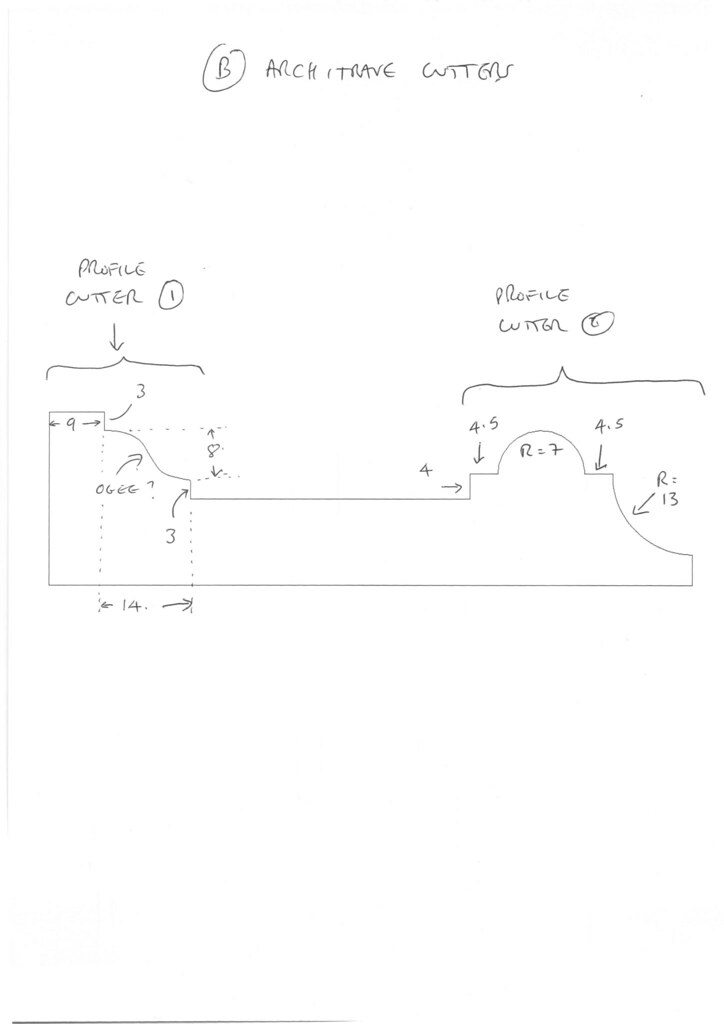

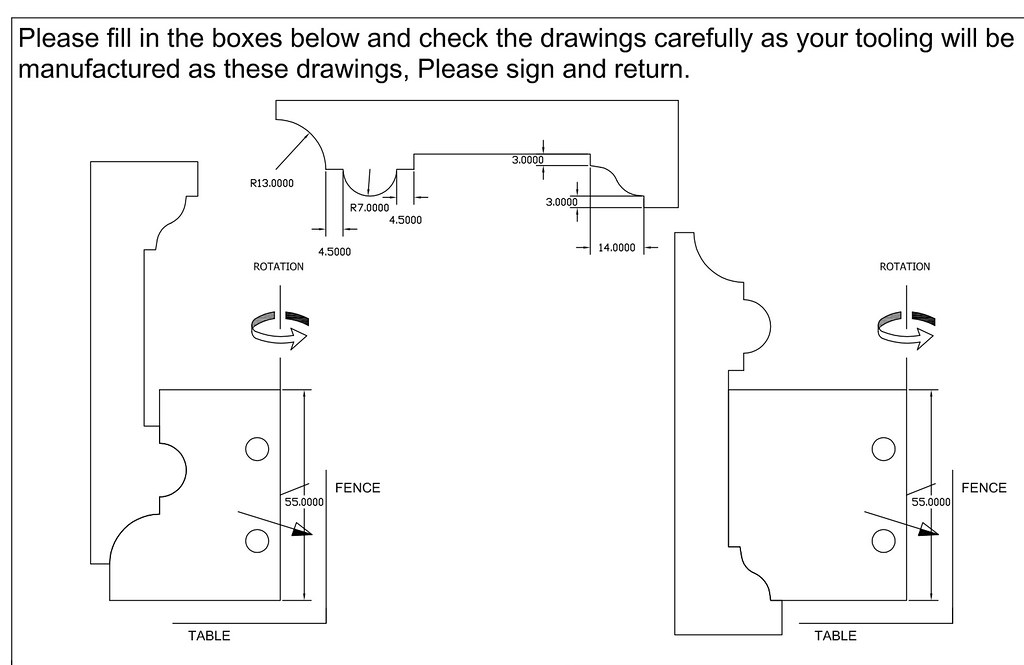

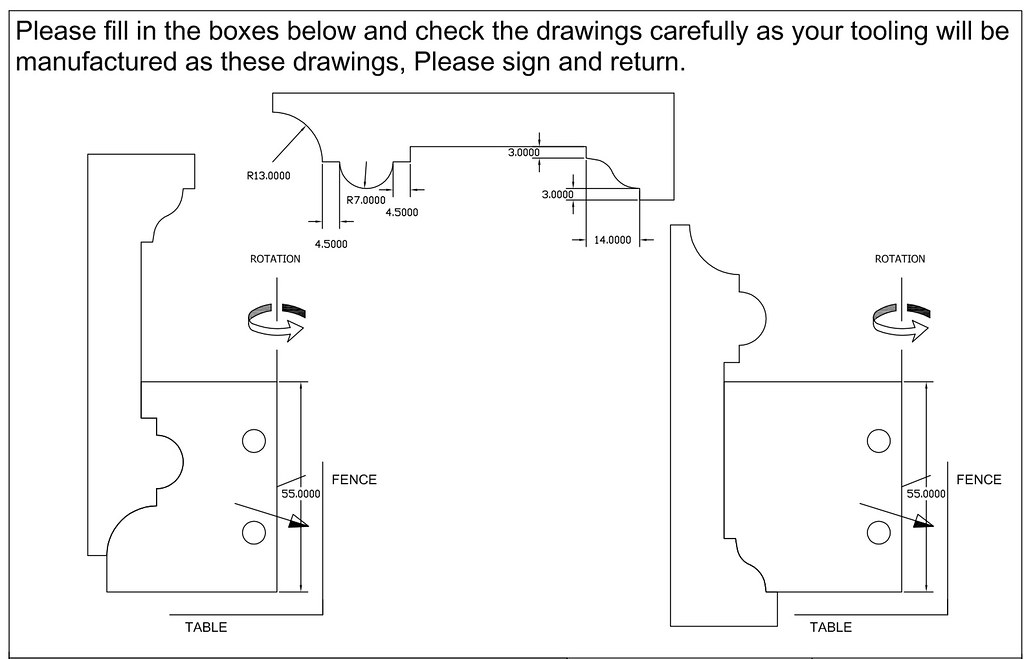

Tarted up and submitted to Whitehill

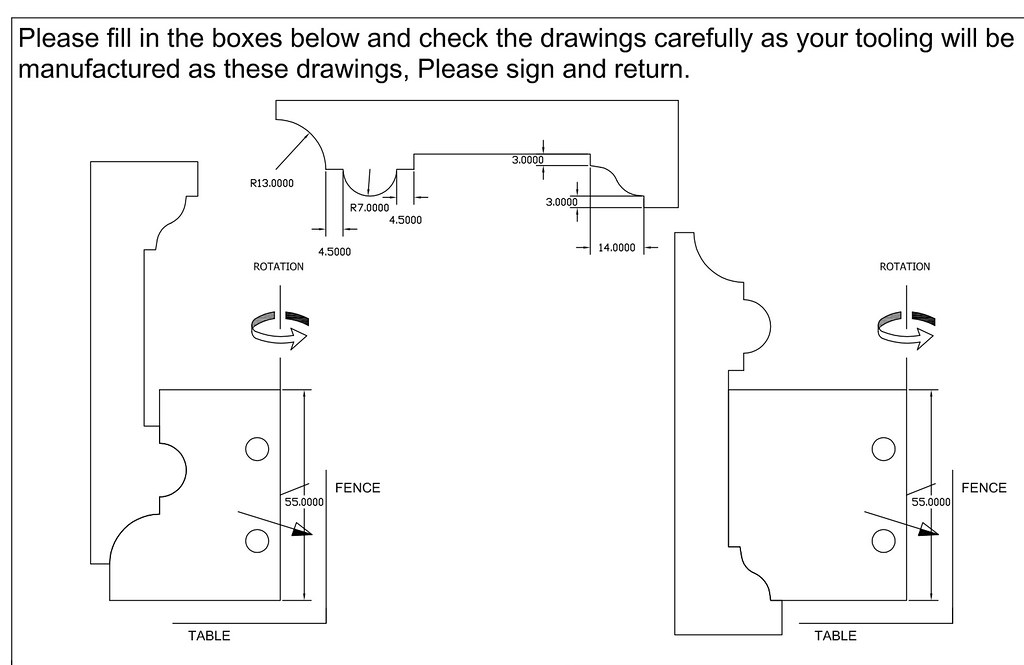

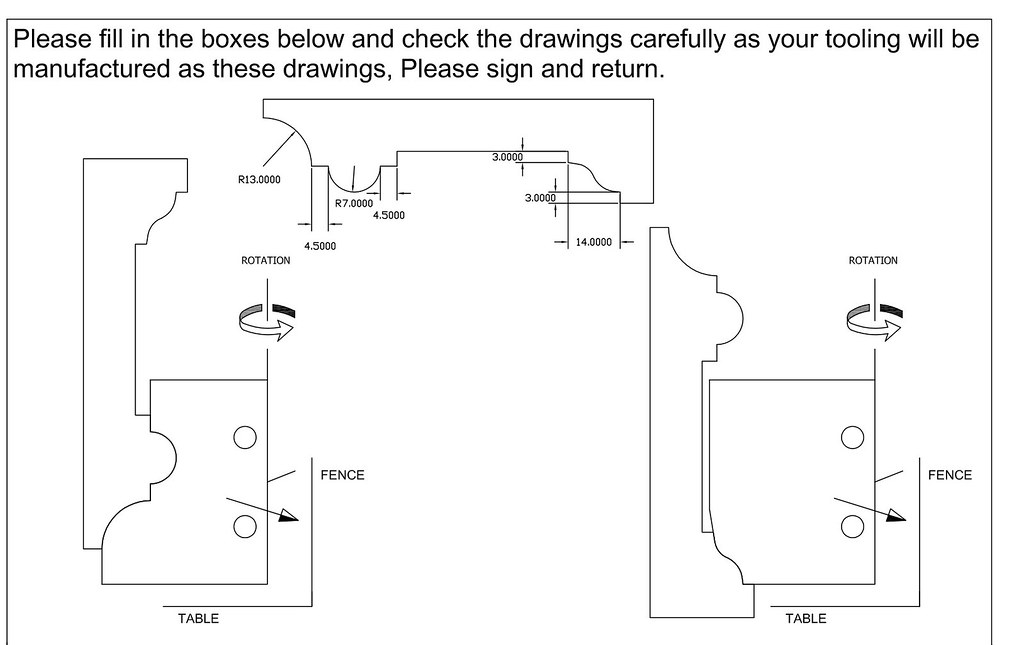

Draft cutter schematic from Whitehill

I then suggested that they could extend the cutters (shown shaded) to avoid me having to make a third pass with a rebate cutter

Second draft

They missed one !

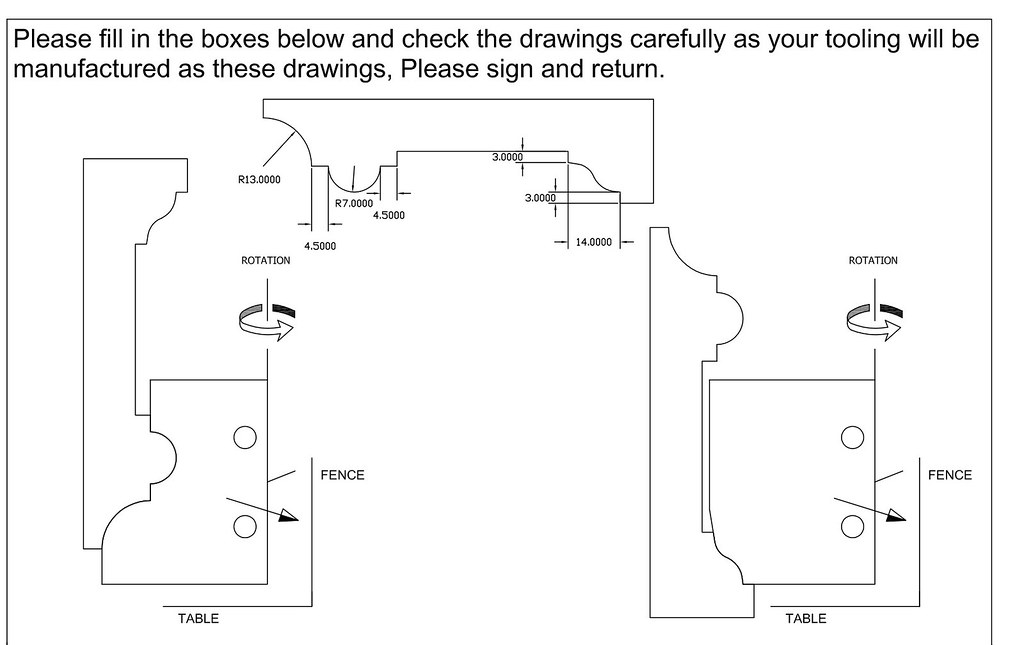

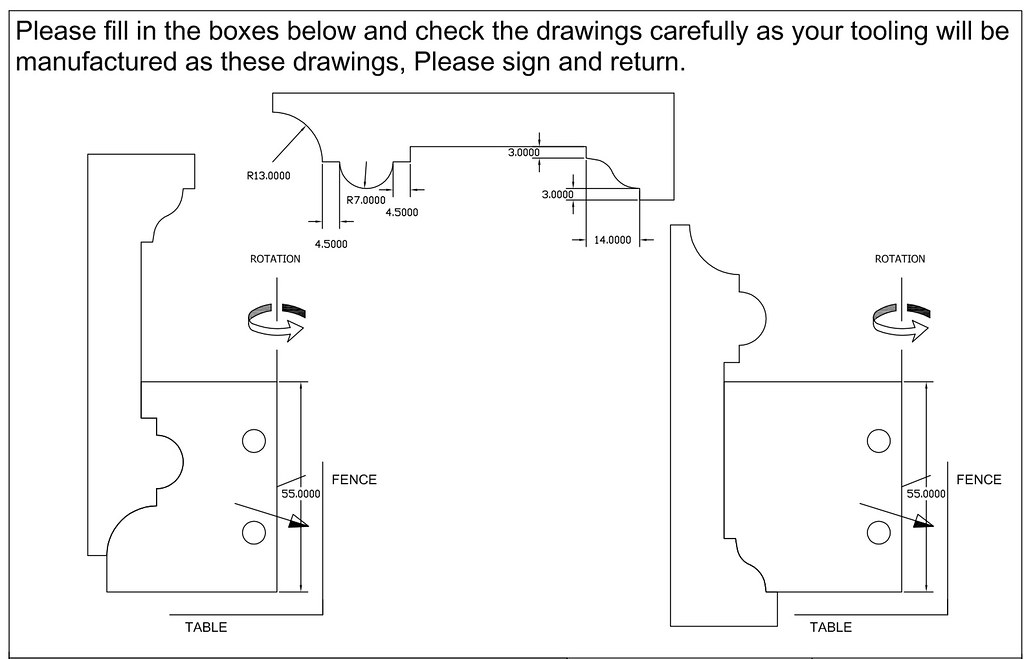

Final signed off cutter drawing

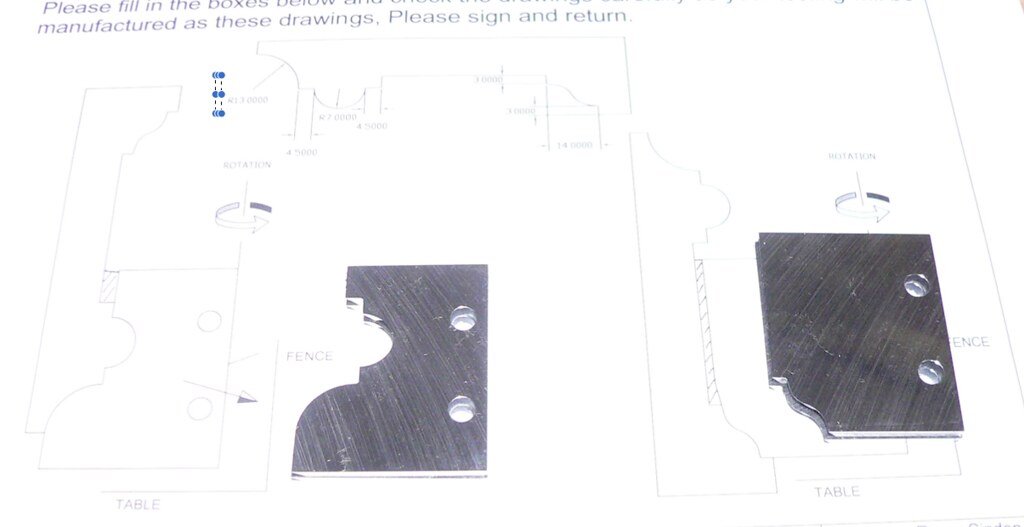

Neither they nor I spotted the oversight aka ****-up which didn't become apparent until I'd finished moulding two sets of architrave

Can you spot it ? As I said, PM me if you can.

Not a complete disaster and not that obvious on the finished product and I doubt that anyone would notice it. It's easily fixable for the remaining 12 sets.

To recap

This is the architrave I wished to make

My working drawing

Tarted up and submitted to Whitehill

Draft cutter schematic from Whitehill

I then suggested that they could extend the cutters (shown shaded) to avoid me having to make a third pass with a rebate cutter

Second draft

They missed one !

Final signed off cutter drawing

Neither they nor I spotted the oversight aka ****-up which didn't become apparent until I'd finished moulding two sets of architrave

Can you spot it ? As I said, PM me if you can.

Not a complete disaster and not that obvious on the finished product and I doubt that anyone would notice it. It's easily fixable for the remaining 12 sets.