No Jig is going to give you "A Long Grind Profile" automatically.

No matter which brand or style of jig you use the actual profile achieved is down to the operator.

The dwell time on wheel (belt) of any particular facet of the tool determines the amount of metal removal and it is this that forms the profile, all the jig will do is allow you to swing the tool in the same arc consistently.

The arc you swing the tool tip in relation to the abrasive determines what profiles/angles are achievable.

You need to study the effects that both the distances of the pivot point of the jig and the length of protrusion of the tool tip have on the shape produced, they have a complimentary effect working with the jig angle setting.

The position of the tool tip on the curve of the wheel (or belt slope) also has a marked effect, so height of pivot point comes into play with the tool protrusion.

There is no one definitive setting for any grind, once you have determined the settings for your particular setup and the shape/angle you prefer for a tool then note them for future use.

Those settings may well be different for each and every tool dependant on your preferences.

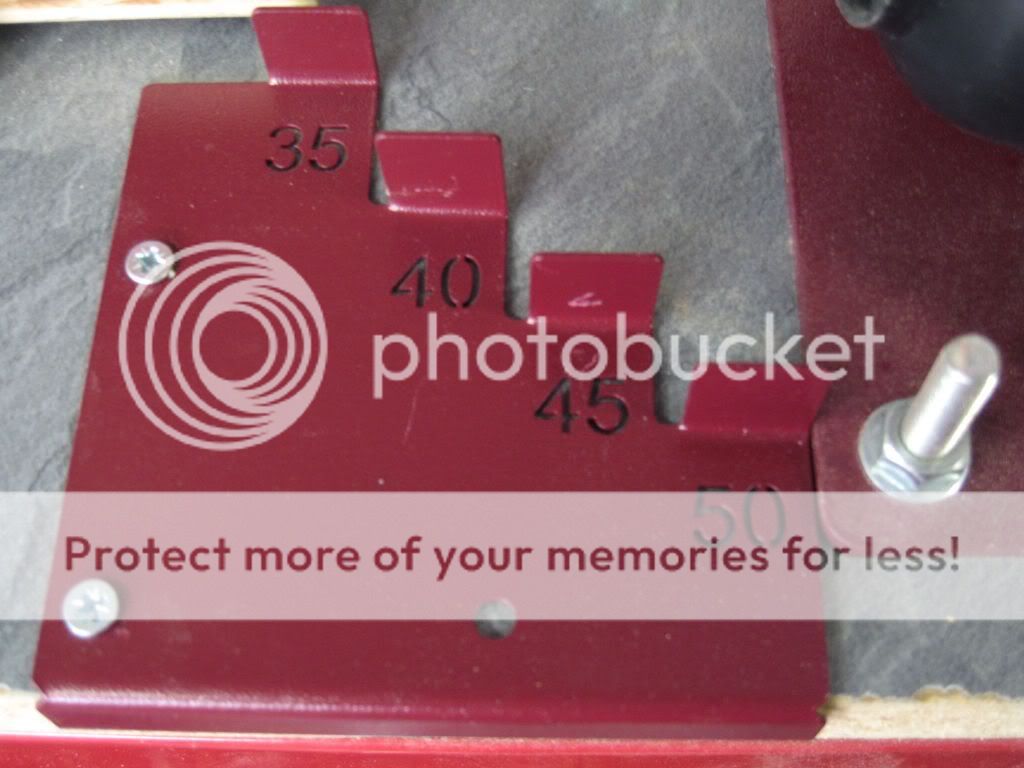

To save constantly changing settings I have three 'bowl gouge' jigs based on the Tormek pattern (same as used by Sorby) set to different angles for different gouges, but even then the spacing distance of the pivot point (base) from the wheel and the tool tip protrusion is again different for some profiles.

Spacers and setting blocks carry the angles and tool details on each so that when diving into the draw weeks latter I don't have to scratch my head as to which settings are needed.

If at all possible try and standardize on a pivot base/wheel (belt) centre height that will give you the profiles you require by adjusting the swinging jig dimensions/angles, that at least will remove one variable.

The very long Ellsworth ? grind is the most difficult to achieve with the jig.

Each tool manufacturer may, even will, have a different flute profile this will also mean that what is good for one gouge won't work with another, only the operator watching how much material is being removed on each facet is the only determination of shape.