Bod

Established Member

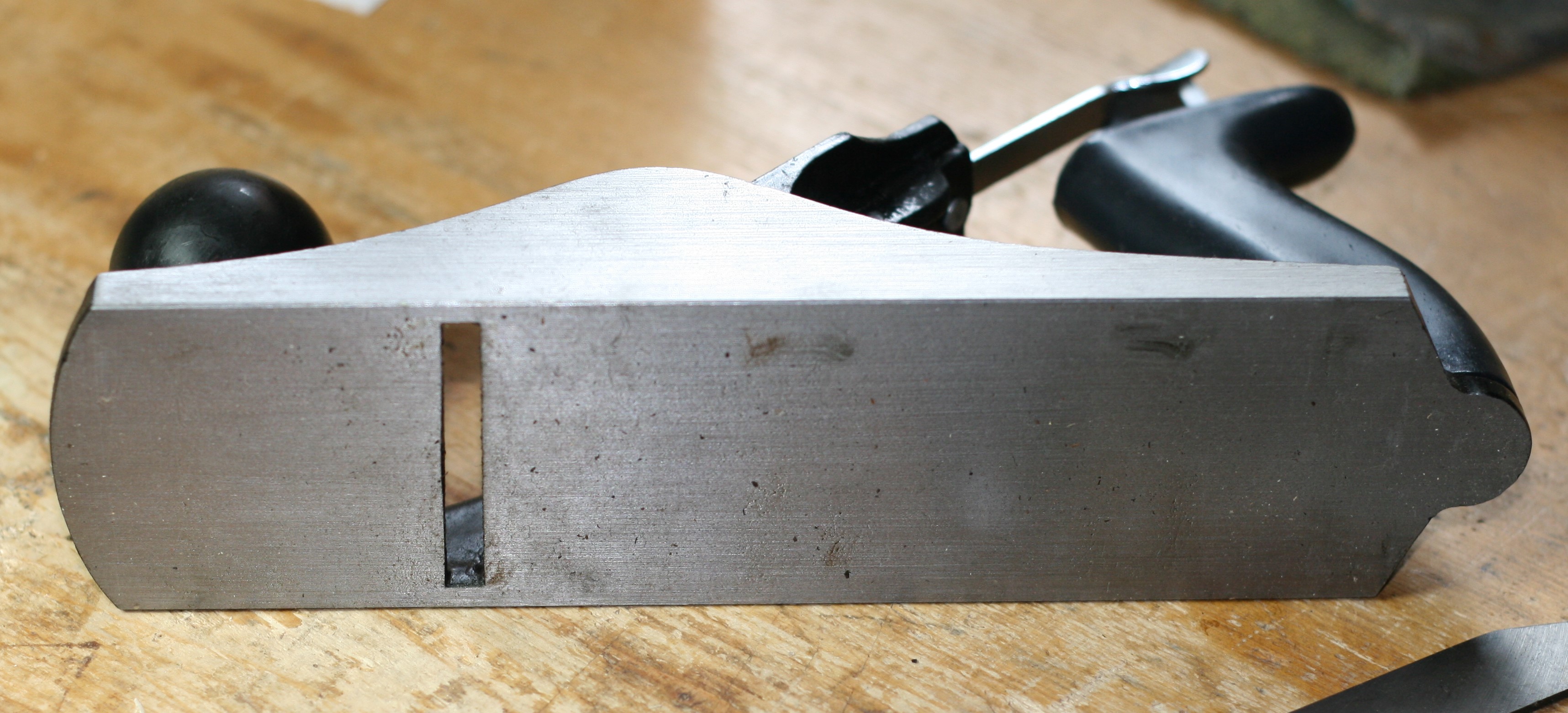

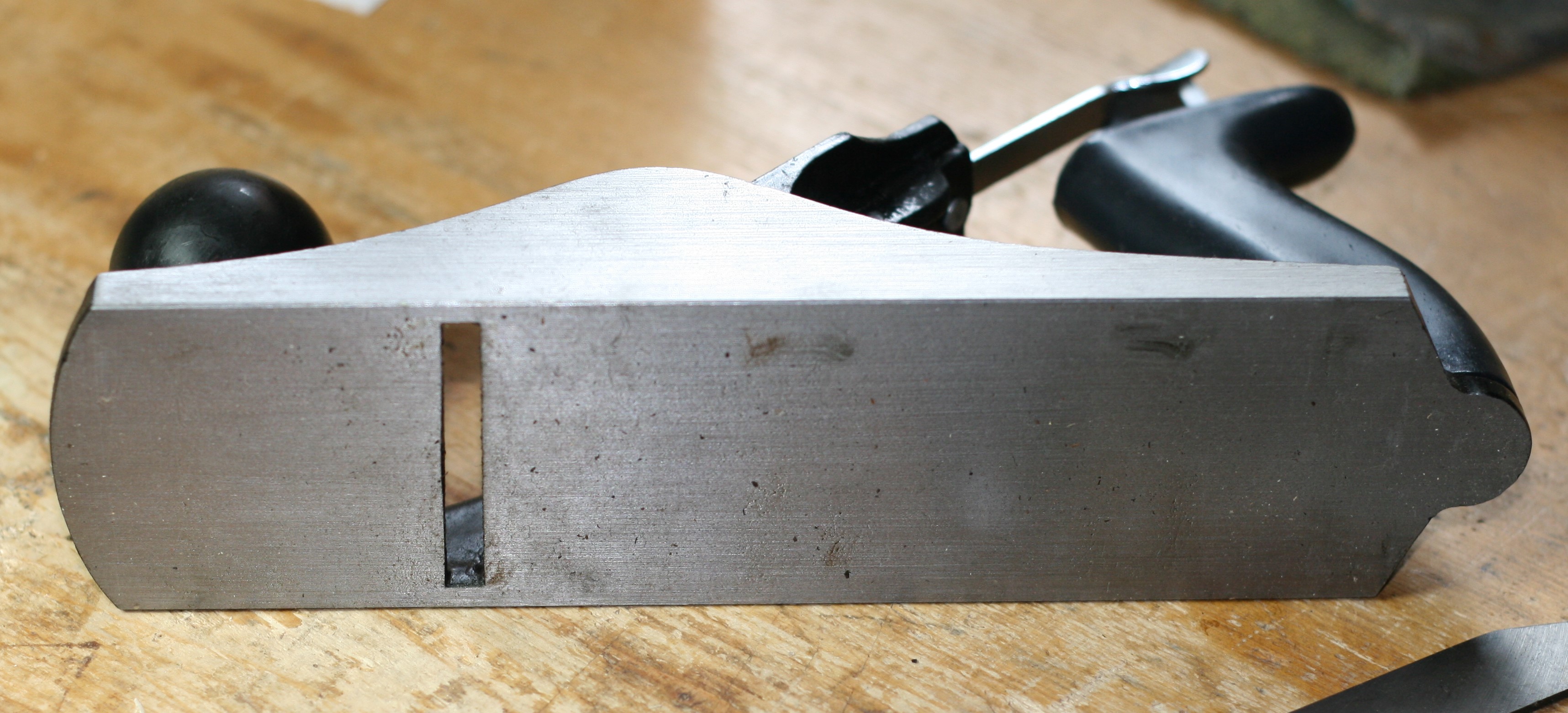

I've just been given a new plane!

The story is this was recovered from the company skip, by a friends son who worked there at the time.

Unfortunatly there are no instructions with it, nor are any easily available on the internet.

So I will go with the normal "Needs sharpening out of the box"

Impressions.

It's cheaply made, will need a bit of work to get it working, and comfortable to use.

The lateral adjuster is very stiff.

The depth adjustment is very loose, the two parts of the yoke are not firmly joined together, and there is a great amount of slack in the blade movement.

There is the grinding angle information on the cap iron, the frog adjustment system, and lateral lever style of the later Record planes. But it's not a "Record".

Do I just hone the bevel as is, or flatten the back of the blade to give it a real chance of working properly?

I do not intend at this point to put a square or straight edge over it. Only to see if it will work "out of the box"

This is my first chance to use a new No 4 plane, all my others have been previously owned, the oldest being a Sweetheart stanley, the youngest a mid 1950's Record, via a 1946-52 WS.

Have I missed much by not having new?

Bod.

The story is this was recovered from the company skip, by a friends son who worked there at the time.

Unfortunatly there are no instructions with it, nor are any easily available on the internet.

So I will go with the normal "Needs sharpening out of the box"

Impressions.

It's cheaply made, will need a bit of work to get it working, and comfortable to use.

The lateral adjuster is very stiff.

The depth adjustment is very loose, the two parts of the yoke are not firmly joined together, and there is a great amount of slack in the blade movement.

There is the grinding angle information on the cap iron, the frog adjustment system, and lateral lever style of the later Record planes. But it's not a "Record".

Do I just hone the bevel as is, or flatten the back of the blade to give it a real chance of working properly?

I do not intend at this point to put a square or straight edge over it. Only to see if it will work "out of the box"

This is my first chance to use a new No 4 plane, all my others have been previously owned, the oldest being a Sweetheart stanley, the youngest a mid 1950's Record, via a 1946-52 WS.

Have I missed much by not having new?

Bod.