I used to hone freehand, cause that was the way it was done in my day, but I always wondered if I could make something that would make the job easier. In those days grinding followed by honing on the 'India' oilstone, was the norm and I have to say until recently that was how I did it. Now, due to unforeseen circumstances, I have to do it differently.

The greatest thing, to me, was finding a diamond sharpening plate (my 'India' oilstone having been nicked) a very cheap (£3.99 I think) medium grit 6"x2" steel plate about 5/16" thick, which I glued onto a piece of mahogany. This worked very well, improving my blade stock quite considerably, but once I got a honing jig (Faithful, cheap from Amazon and free delivery) I've never looked back. I have recently acquired a set of three diamond honing sheets, c/w dust holes, which are crimped to coloured plastic sheets

£2.99 from Lidl's I siliconed them onto a piece of mahogany (with heavy plane on top to assure flatness) as they are quite light and flexible, cheap and cheerful didn't expect much,

boy was I wrong

![ATTACH]](https://proxy.imagearchive.com/4a5/4a5179c073dbb8e5c6f85757fa50d4c1)

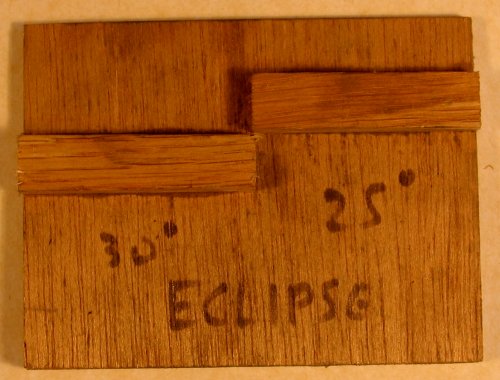

With the coarsest grit sheet and the honing jig, I have taken all the blades in my shop to a suitable single bevel, even a 1/8" chisel which I griped below the recommended jaw positions, touching the guide bars and setting to angle by sight. No grinder has been used, normally it takes 10-20 mins to cut the bevel of a plane iron to say 35 deg. which isn't bad considering it only needs doing once, I have become so proficient that I can now set the blade in the jig protruding almost exactly right, a quick measurement confirms the exactitude (either 48 or 45mm in one instance) square and straight almost to the point of clinical, in fact I have to remember the need to take the outer points off the blade to prevent marks on the wood planed. This is done almost in the mind for my smoothing, try and bench planes, but physically sighted on the jacks and roughing planes to get a nice easing camber. I polish my single bevels on an 'Escher' waterstone (possibly the finest, according to some oficiados, I couldn't comment) and achieve the sharpest blade edges ever.

That's my story for what it's worth, I think my message is have an open mind mind "one man's meat is another man's poison" etc. so don't be scared to try whatever you've read so far, if it sounds right to you go for it...bosshogg

"Ethical axioms are found and tested not very differently from the axioms of science. Truth is what stands the test of experience." A.E. 8)