mailee

Established Member

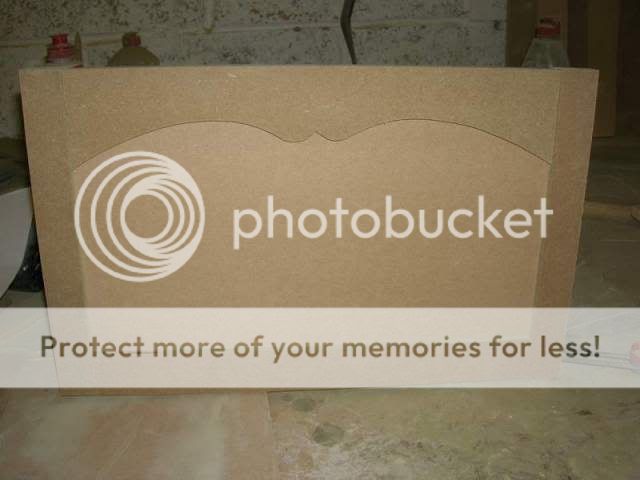

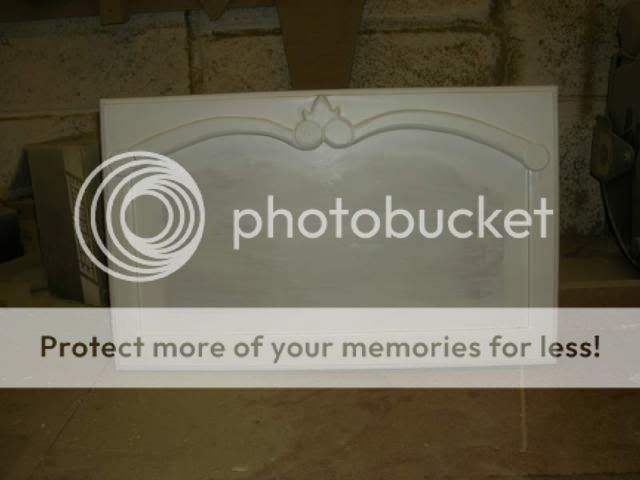

I made a start on the Shabby chick bedroom suite today. After returning from the timber merchants with three sheets of MRMDF I got cutting and started putting pieces in place:

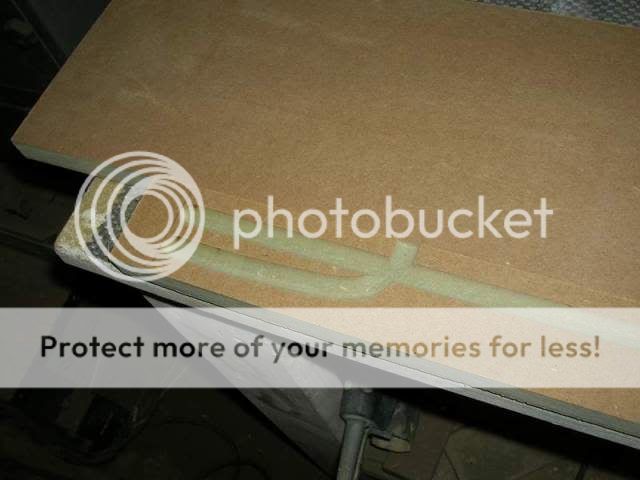

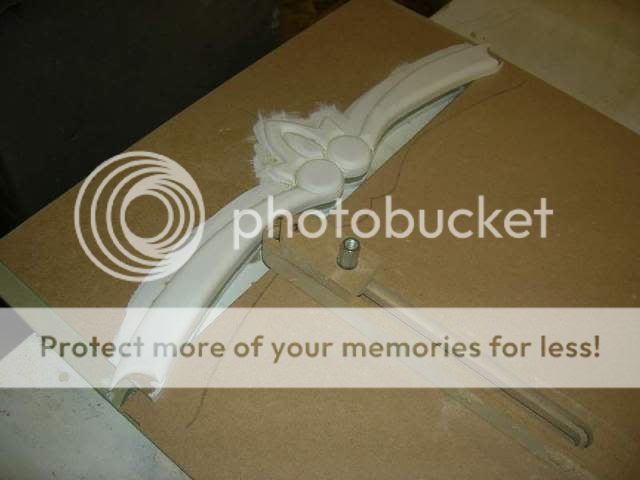

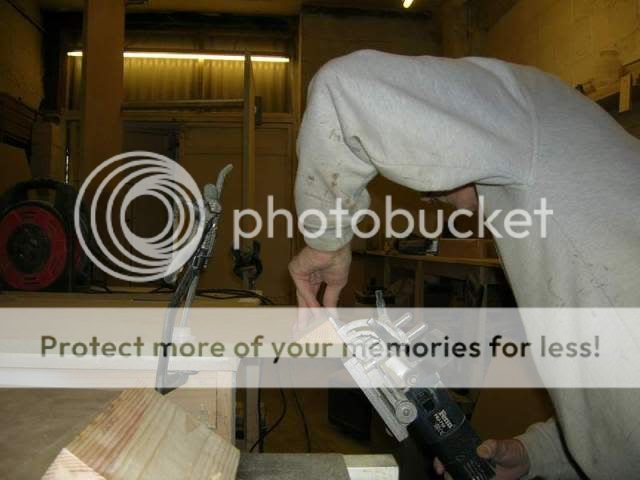

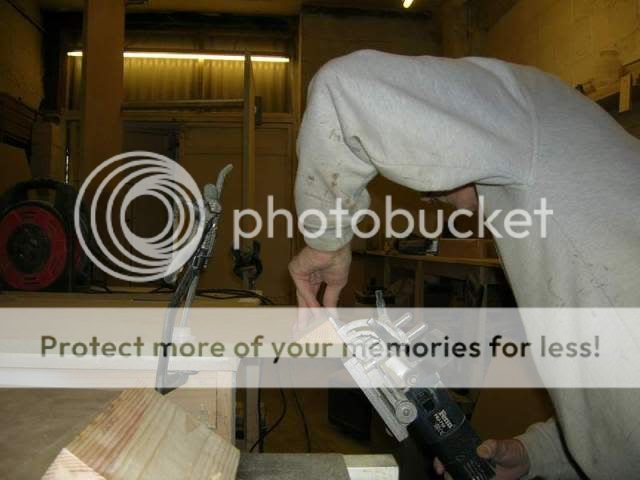

I did have some fun and games with the biscuit angles on the left hand unit top but resorted to using a block to angle the jointer.....very carefully making sure the depth was correct: :lol:

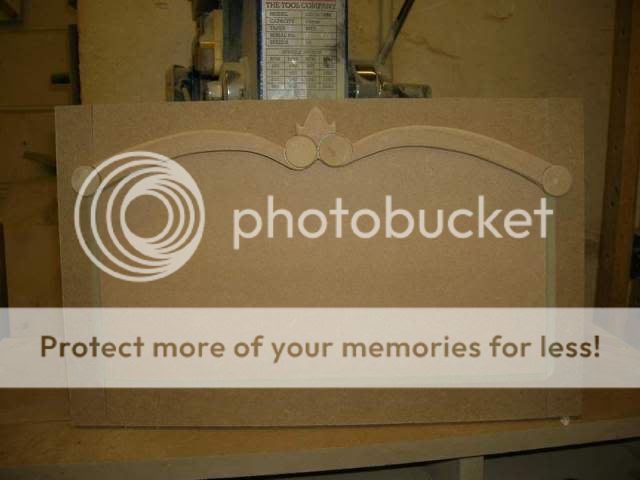

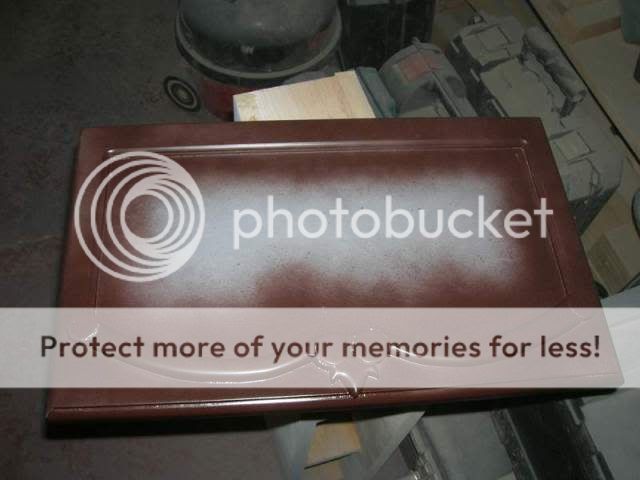

I then made a start on making up a face fame for the front. This will also be made out of MDF as it's main use is to be used as a scribing strip to the left and top. I also have to space it off to miss a radiator.

I will have to get some more MDF tomorrow to carry on. I NEED a van desperately, it is in hand though.

I did have some fun and games with the biscuit angles on the left hand unit top but resorted to using a block to angle the jointer.....very carefully making sure the depth was correct: :lol:

I then made a start on making up a face fame for the front. This will also be made out of MDF as it's main use is to be used as a scribing strip to the left and top. I also have to space it off to miss a radiator.

I will have to get some more MDF tomorrow to carry on. I NEED a van desperately, it is in hand though.