OK, so Mel has been nagging me about "Name that Machine", but I decided to do something a wee bit different. "How about a quiz or two with a few NTM's thrown-in for good measure?", I thought. So here's the first part, just a quiz with a NTM to appear tomorrow. These are a mixture of hand tool woodworking, machine woodworking, history, etc. and are in no particular order. The ones in blue have not yet been solved, those in red are soloved with the answers in green. Enjoy!

1. Bearded, Manchester, Merrick and Turpentine are all forms of which tool?

Answer (Alf): Axes (who's been looking in Salaman, then? :wink: )

2. In British practice on which machine would one normally find a lengthing saw?

*** Well nobody even tried this one. C'mon joiners, where were you? The answer is, of course a single-end tenoner and a lengthing or cut-off saw is used to trim the tenon to length after it has been worked by the tenoning and scribing heads.

3. What was Jack Millet better known as, and why?

I'll give you a clue - the answer is in Salaman - somewhere......

Answer (Alf):

4. What is the correct peripheral speed required for a circular saw sawing timbers?

Answer (woodbloke): According to 'The Woodworkers Pocket Book' by Charles Haywood the peripheral speed of a tooth on a circular saw..... 'should be in the region of 3,000m per minute'

5. This well-known English brand name once traded under the "Shamrock" brand. Who were they?

Answer (woodbloke/Alf): Marples who had the Shamrock as a logo... and yes, Alf, it was William not Joseph (corrected)

(corrected)

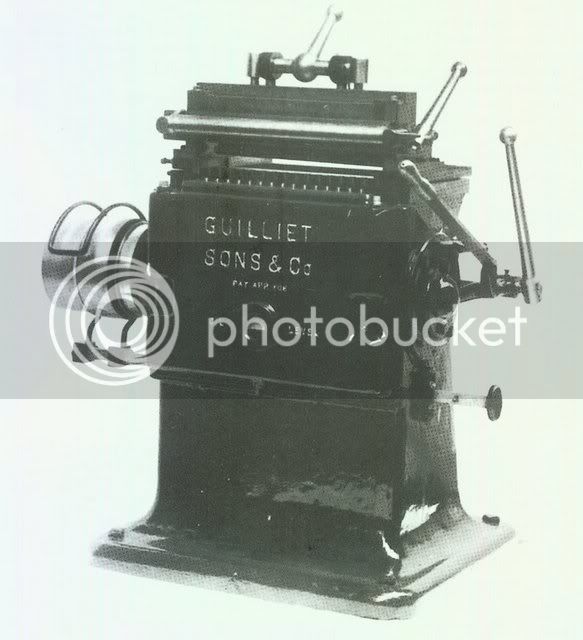

6. Probably my most famous machine was originally designed and made for Guillet et Fils in the days of lineshaft drive. Later machines carried my name and the last machines were branded with the name of another British stalwart. The machine I am referring to was, amazingly, in production from the 1920s for more than 70 years and still commands good prices today. Who was I and what was the machine?

Clue: Tools for this machine are still mentioned specifically in both Titman and Trend catalogues. OK, so this is a bit "Name That Machine"-ish..... :?

*** Again no takers, although I suspect that we have one or two people on here who would recognise the name of R. S. Brookman who's well-known semi- and fully-automatic dovetailers are still in use all over the world. Brookman originally designed his machine for Guillet & Fils of France

and that was back in 1929. the machine was still being manufactured into the 1990s and was laterly sold as a Wadkin-Brookman, Wadkins having purchased the Brookman firm in the late 1980s I believe. So many of these are still in daily use that Titman and Trend both offer replacement tooling, as do a number of the Continental manufacturers such as CMT.

Brookman's other innovative designs included a hydraulically operated chain and chisel mortiser regarded by many as the best machine of its' type ever constructed

7. A famous English toolmaker some of my designs have passed through several hands and were still made until recent years. The main portion of my business eventually became part of an American business whilst another arm of my business ended-up with one of their one-time rivals. What was my business name?

Answer (Alf, 2nd stab!): "Well I almost said Edward Preston..... ". In fact spot on. Edward Preston were taken over by the Birmingham rulemakers, Rabone (now part of Stanley, an American company - "the main portion of my business (rule making) eventually became part of an American business") during the Depression. Rabone's weren't really interested in the plane side of the business and disposed of it to the Hampton family (aka Record), who these days are just another brand name of American Tool (aka Irwin)

8. One for the wood machinists. Name four methods of machine mortising (I know of five, so this could prove interesting.....)

Answer (Alf): Hollow chisel mortiser, slot morticer......

Answer (JasonB): ... you can add a chain morticer..... and he also got the Maka (swing or oscillating chisel) mortiser

OK, so we're up to four. The last one is French and like Hoover is frequently named after it's original manufacturer. It is mentioned specifically by technical books on the subject of wood machining.......

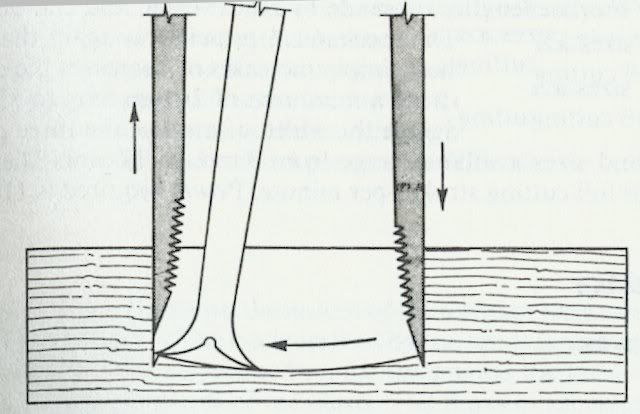

*** The fifth method I was looking for is generically referred to as an Alternax mortiser after it's originators. Whilst this is a French specialty these machines are extremely quick and have spread throughout the world since the 1960s with companies such as Sauterau manufacturing thousands of machines. the principle can be seen here:

The ends of the mortise are formed by two stabbing which are stabbed into the work and withdrawn whilst the waste material between is removed by a swing chisel. Unlike the Maka mortiser these devices will allow the cutting of through mortises (Makas only accommodate stopped mortises, but they can have tooling made to cut a mortise and a haunch in one operation).

As both the Maka and Alternax types can cut at up to 1500 strokes/minute even taking just 0.5mm/stroke means that mortises are machined incredibly quickly

9. What is the effect of unprotected iron or steel in contact with walnut in an exterior setting?

Answer (Alf): It rusts. Maybe something happens to the walnut too, but the metal will definitely rust... (partial answer only)

*** The other bit missed is that walnut, like oak, contains tannin. So water reacting with the tannin in the timber may well cause black staining.

10. Why should the name of Hermann Steiner be familiar to many modern woodworkers? (It isn't, but he invented something significant)

Answer (Alf) : The biscuit jointer. Sadly Hermann passed-away last year. There's a page on Steiner-Lamello's history here

Answers, please, on a £20 note to.....

Scrit

PS I'll post the missing answers to this quiz tomorrow when I post the next "Name that Machine"

PPS For those who are avid "Googlers", I've checked - some of the answers can't be found that way :wink:

1. Bearded, Manchester, Merrick and Turpentine are all forms of which tool?

Answer (Alf): Axes (who's been looking in Salaman, then? :wink: )

2. In British practice on which machine would one normally find a lengthing saw?

*** Well nobody even tried this one. C'mon joiners, where were you? The answer is, of course a single-end tenoner and a lengthing or cut-off saw is used to trim the tenon to length after it has been worked by the tenoning and scribing heads.

3. What was Jack Millet better known as, and why?

I'll give you a clue - the answer is in Salaman - somewhere......

Answer (Alf):

Well, allright, I never said it would be easy......... Now I'm not sure who is sadder, me for knowing in the first place, or..... :wink:Scrit, you're an evil, sadistic swine! The answer's almost right in the middle of the damn book, you, you...

Anyway, better known as "Pincher Jack" 'cos he was a travelling smith who went all over England and Wales stopping at forges to make pincers out of old files and rasps for farriers and others.

4. What is the correct peripheral speed required for a circular saw sawing timbers?

Answer (woodbloke): According to 'The Woodworkers Pocket Book' by Charles Haywood the peripheral speed of a tooth on a circular saw..... 'should be in the region of 3,000m per minute'

5. This well-known English brand name once traded under the "Shamrock" brand. Who were they?

Answer (woodbloke/Alf): Marples who had the Shamrock as a logo... and yes, Alf, it was William not Joseph

6. Probably my most famous machine was originally designed and made for Guillet et Fils in the days of lineshaft drive. Later machines carried my name and the last machines were branded with the name of another British stalwart. The machine I am referring to was, amazingly, in production from the 1920s for more than 70 years and still commands good prices today. Who was I and what was the machine?

Clue: Tools for this machine are still mentioned specifically in both Titman and Trend catalogues. OK, so this is a bit "Name That Machine"-ish..... :?

*** Again no takers, although I suspect that we have one or two people on here who would recognise the name of R. S. Brookman who's well-known semi- and fully-automatic dovetailers are still in use all over the world. Brookman originally designed his machine for Guillet & Fils of France

and that was back in 1929. the machine was still being manufactured into the 1990s and was laterly sold as a Wadkin-Brookman, Wadkins having purchased the Brookman firm in the late 1980s I believe. So many of these are still in daily use that Titman and Trend both offer replacement tooling, as do a number of the Continental manufacturers such as CMT.

Brookman's other innovative designs included a hydraulically operated chain and chisel mortiser regarded by many as the best machine of its' type ever constructed

7. A famous English toolmaker some of my designs have passed through several hands and were still made until recent years. The main portion of my business eventually became part of an American business whilst another arm of my business ended-up with one of their one-time rivals. What was my business name?

Answer (Alf, 2nd stab!): "Well I almost said Edward Preston..... ". In fact spot on. Edward Preston were taken over by the Birmingham rulemakers, Rabone (now part of Stanley, an American company - "the main portion of my business (rule making) eventually became part of an American business") during the Depression. Rabone's weren't really interested in the plane side of the business and disposed of it to the Hampton family (aka Record), who these days are just another brand name of American Tool (aka Irwin)

8. One for the wood machinists. Name four methods of machine mortising (I know of five, so this could prove interesting.....)

Answer (Alf): Hollow chisel mortiser, slot morticer......

Answer (JasonB): ... you can add a chain morticer..... and he also got the Maka (swing or oscillating chisel) mortiser

OK, so we're up to four. The last one is French and like Hoover is frequently named after it's original manufacturer. It is mentioned specifically by technical books on the subject of wood machining.......

*** The fifth method I was looking for is generically referred to as an Alternax mortiser after it's originators. Whilst this is a French specialty these machines are extremely quick and have spread throughout the world since the 1960s with companies such as Sauterau manufacturing thousands of machines. the principle can be seen here:

The ends of the mortise are formed by two stabbing which are stabbed into the work and withdrawn whilst the waste material between is removed by a swing chisel. Unlike the Maka mortiser these devices will allow the cutting of through mortises (Makas only accommodate stopped mortises, but they can have tooling made to cut a mortise and a haunch in one operation).

As both the Maka and Alternax types can cut at up to 1500 strokes/minute even taking just 0.5mm/stroke means that mortises are machined incredibly quickly

9. What is the effect of unprotected iron or steel in contact with walnut in an exterior setting?

Answer (Alf): It rusts. Maybe something happens to the walnut too, but the metal will definitely rust... (partial answer only)

*** The other bit missed is that walnut, like oak, contains tannin. So water reacting with the tannin in the timber may well cause black staining.

10. Why should the name of Hermann Steiner be familiar to many modern woodworkers? (It isn't, but he invented something significant)

Answer (Alf) : The biscuit jointer. Sadly Hermann passed-away last year. There's a page on Steiner-Lamello's history here

Answers, please, on a £20 note to.....

Scrit

PS I'll post the missing answers to this quiz tomorrow when I post the next "Name that Machine"

PPS For those who are avid "Googlers", I've checked - some of the answers can't be found that way :wink: