transatlantic

Boom!

chiokli":2iqza1lr said:So I bought one of these last week from FFX, and initially I was happy with it after being able to set it up and get it nice and level and square (after also discovering that the leg assembly did not have any fixings included).

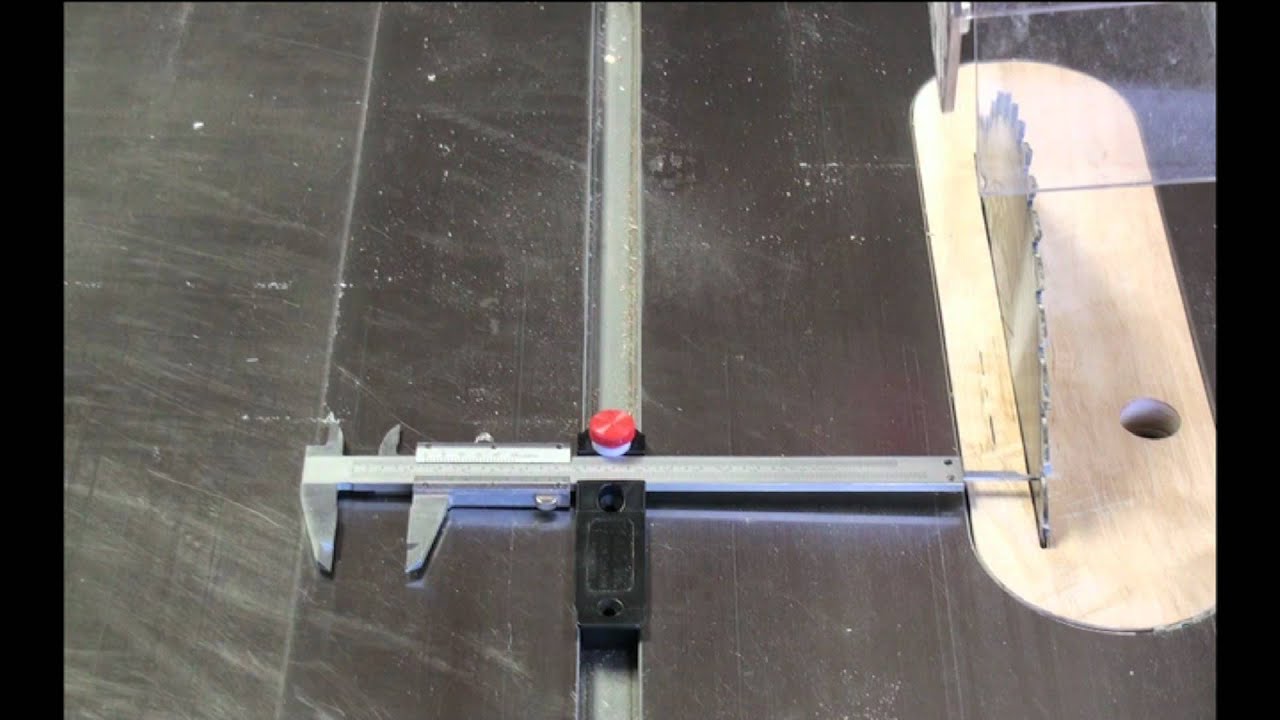

On using it today, I've discovered that the top is not flat specifically on the right side between the blade and the mitre slot. It is flat front and back, but across the centre of the table (parallel to the axle), it has a bit of a "bulge". This has made checking the blade for 90° to the table problematic, especially as the insert plate isn't perfectly flush with the table either. The top is cast aluminium, and I'm not sure how to solve this, if at all.

I realise paying £229 for a table saw is expecting some fettling, but I don't how if I can fettle this issue.

How big of a bulge are we talking? how 'high' above the rest and over what size of area?

I have had good success in improving the flatness of my cheap surface planer by attaching Wet/Dry to some float glass (that I already had) and using circular motions to average things out. Obviously it won't be perfect, but it is much better than it was. This was easier in my case as I wast able to take the infeed table to the float glass (it's a very small planer).

The table has some thickness, you might be able to try it. Assuming we're only talking about fractions of a mm .. In your case, you might get better results by using some thick MDF and a roll of 180 grit paper. Maybe also with some steel tubing attaching to the MDF to keep it flat. But I suspect you won't want to do this due to voinding the warranty.

Have you also checked it's not something underneath pushing up too much that might be causing the buldge?