transatlantic":wqc7827j said:I'll try and get some photos for you

:mrgreen: :mrgreen: thanks!!

transatlantic":wqc7827j said:I'll try and get some photos for you

Nygie":1jy7snyv said:Ok got the hole in the saw shelf and a boxy type (triangle shape) attached underneath and a hole for sticking the vac in.

The next thing I was thinking was should I cut an inch off the extractor port on the saw and cover the curved hole (to reduce dust exit) and rely on extraction fom the collector box. Or do people remove the shroud under the table?

Still use the extracor port on the back of the saw?

AS you might guess this is my first table saw

Cheers

Arvacon":160ko46x said:Any news about that photos?

transatlantic":2lreql93 said:I think you'll have to experiment. My thoughts would be to use the extraction port as it was designed (as there is a "sealed" container around the trunnion mechanism), and just let any other dust fall through the hole with gravity (empty it out when needed), and cover as many other gaps as you can.

I assume you made something like this ? I'd go with a box, as I'd guess it'll fill up pretty quickly.

The gap around the angle adjustment will be an issue. For that, most people cover it with tape, and then cut a line for the shaft to move along (the tape will bend).

Nygie":3j5ym4e3 said:transatlantic":3j5ym4e3 said:I think you'll have to experiment. My thoughts would be to use the extraction port as it was designed (as there is a "sealed" container around the trunnion mechanism), and just let any other dust fall through the hole with gravity (empty it out when needed), and cover as many other gaps as you can.

I assume you made something like this ? I'd go with a box, as I'd guess it'll fill up pretty quickly.

The gap around the angle adjustment will be an issue. For that, most people cover it with tape, and then cut a line for the shaft to move along (the tape will bend).

Thanks for that, my box looks similar but rougher.

I think I'll try the tape method as described. Cheers.

transatlantic":3h1jbopu said:Arvacon":3h1jbopu said:Any news about that photos?

Sorry dude, haven't had a chance as when I leave for work, it's dark, and when I come back it's dark. So will have to wait until weekend. I'll try taking some tonight with my garage light to see how bad it is, but usually, my camera won't focus

Arvacon":w8d2yz7x said:Hi transatlantic, thanks for the photos.

I haven't check this thread since last time you told me about the pictures, so I just saw them.

For some reason the forum platform doesn't send me email notifications about new posts.. I have checked the box of "Notify me when a reply is posted" choice.

Arvacon":35khgszp said:Yes they have enlighten the things a lot.

Mine is on the road now.

Arvacon":2x8xtjt3 said:Hi transatlantic and everyone.

I have received mine finally. First impression was ok, although I had a disappointment with the package, as the German eshop sent me a probably returned or expository item, as the box was already opened and the items were removed from the plastic bags too. Because I live in Greece, after I inspected the saw I decided to not argument with them and just keep it, as it would be difficult to send this back and take my money without having troubles, so I was feeling discouraged to do this and tired of waiting to do my work.

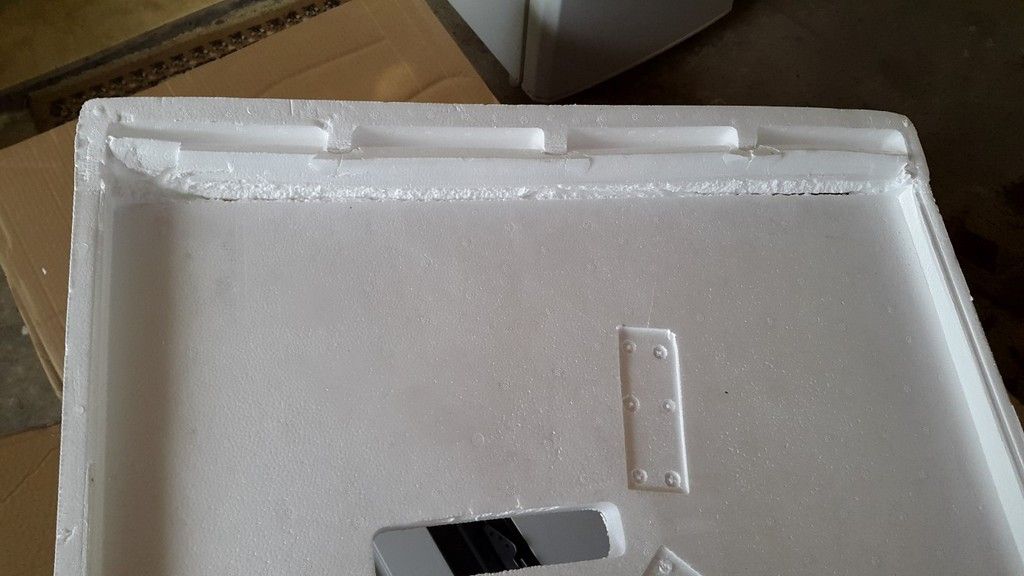

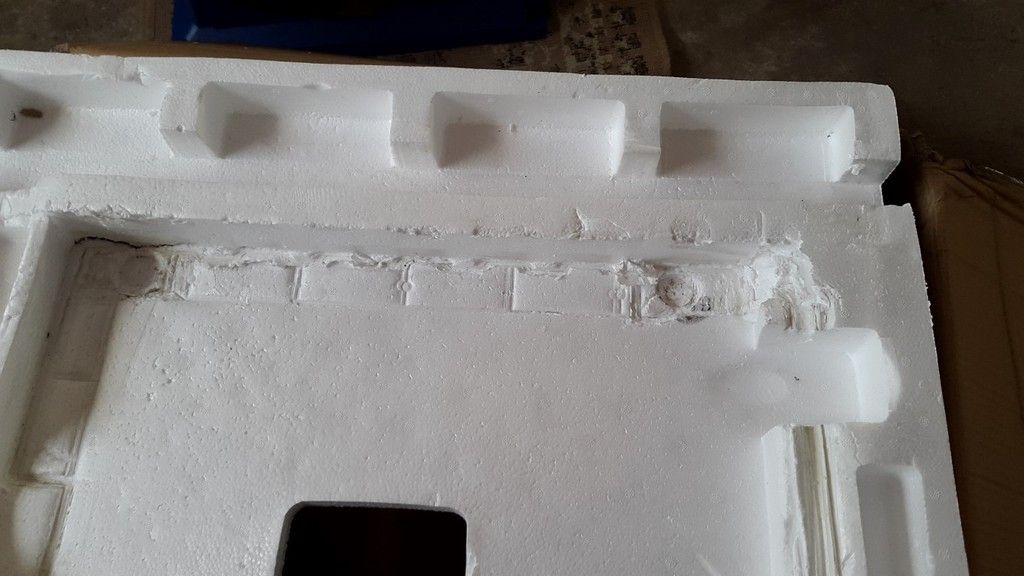

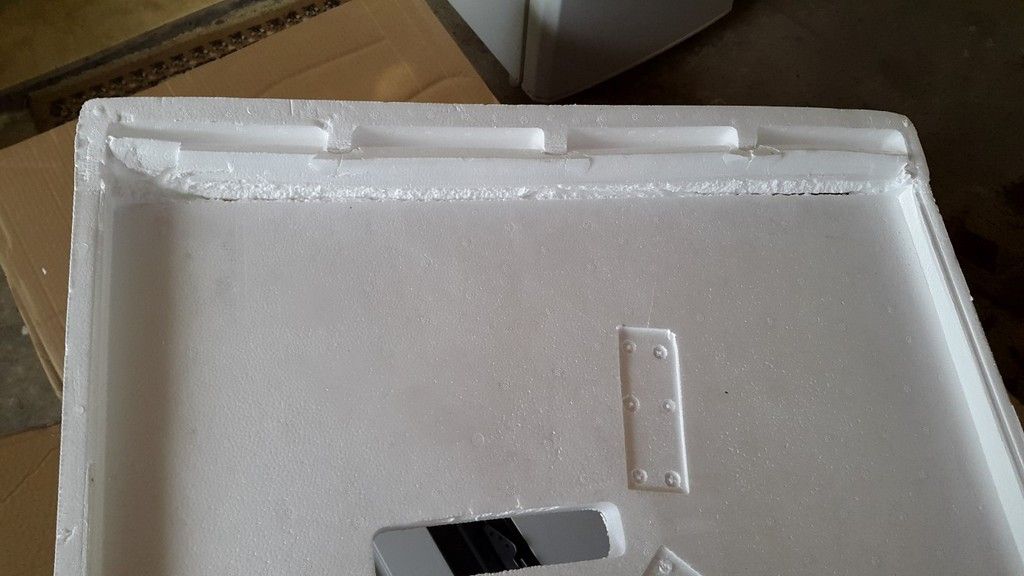

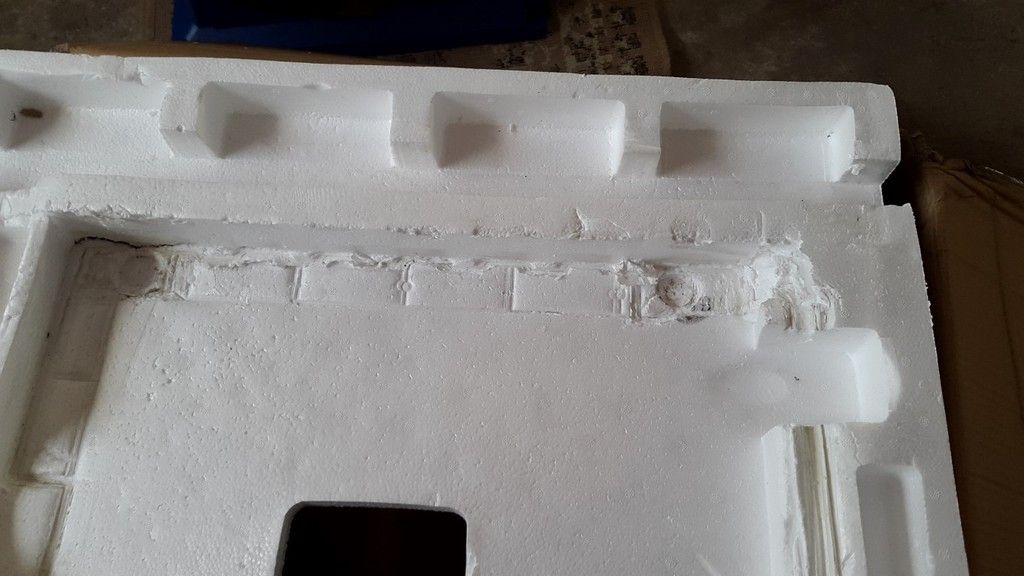

The box came almost open, with old unglued packing tape that it was passed several times up to the top. This guy didn't bother even to use some new packing tape at all, although he promised me that he would taking extra care of the parcel to be very carefully protected, but finally he did the opposite, so that was very frustrating. The box came without pallet, it had a strong hit at one side, but fortunately the styrofoam even it has broken from the impact, it saved the saw. Only the rip fence is a little bend at the back side (but I will fix this), because it was not at safe position, as they had just throw all the spare parts beside the saw randomly.

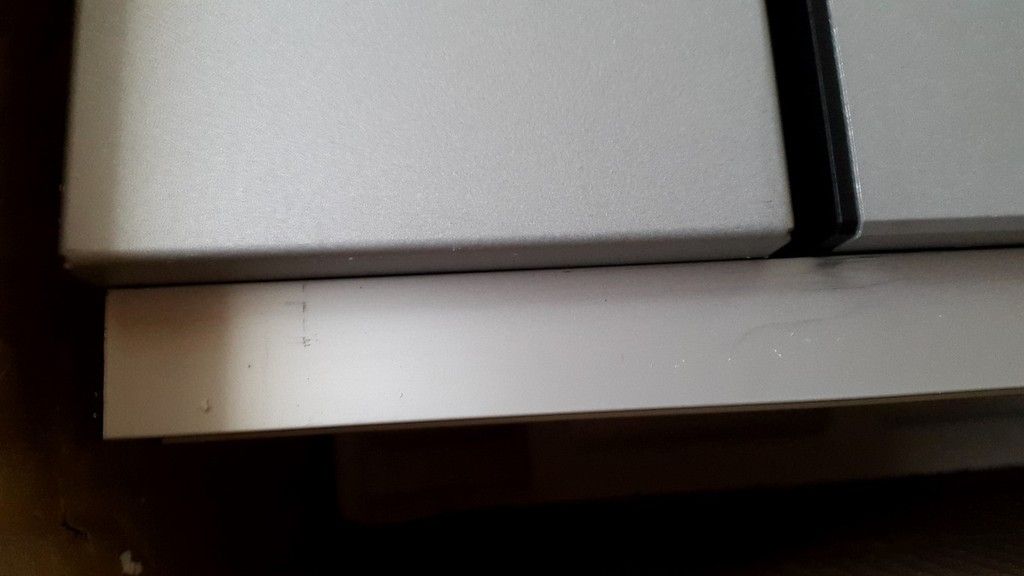

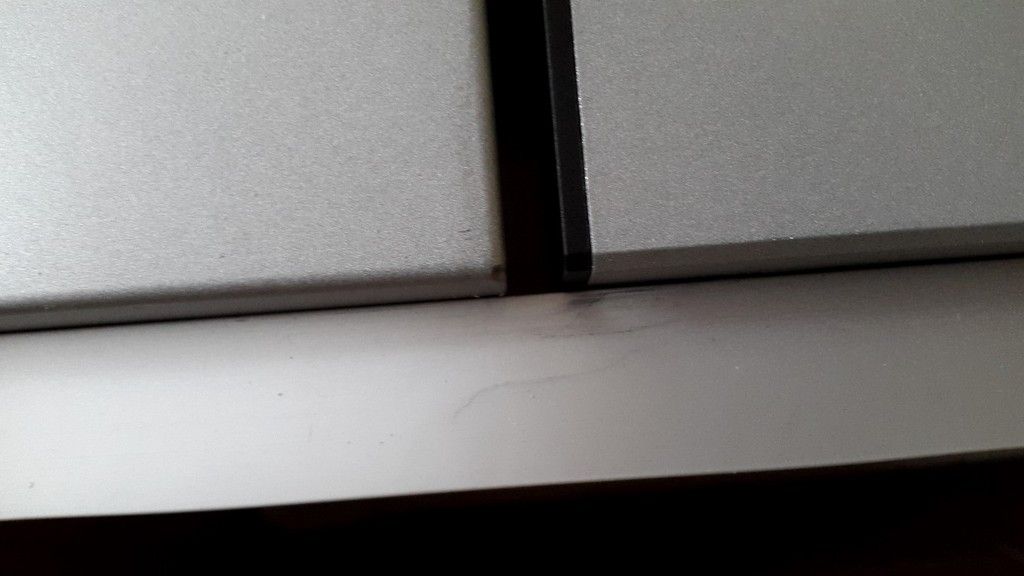

At least the machine seems it had never been working again. I checked for the blade and it runs true. The table seems flat with a small gap at the left and right end sides, but this is under 0.5mm I think. This divergence seems to be at the parts that they are at the out side of the mitre guides. The blade is not parallel with the guides, so it need some work to become aligned and ready for use. The lift mechanism seems to need some improvement too, as it needs a little force to turn the handle. I noticed also the little change of the disk's angle, in the last ~5% of the height adjustment mechanism, that you had mentioned before, but there is a way to fix this problem and use the 100% of high I think.

I decided to disassemble everything and start assemble all the parts from the beginning, to be sure that everything is aligned correctly. I am used to doing this when I buy new Chinese tools, as at the past I have found a lot of unscrewed screws and misalignments. Indeed in this saw I found some important screws unscrewed too.

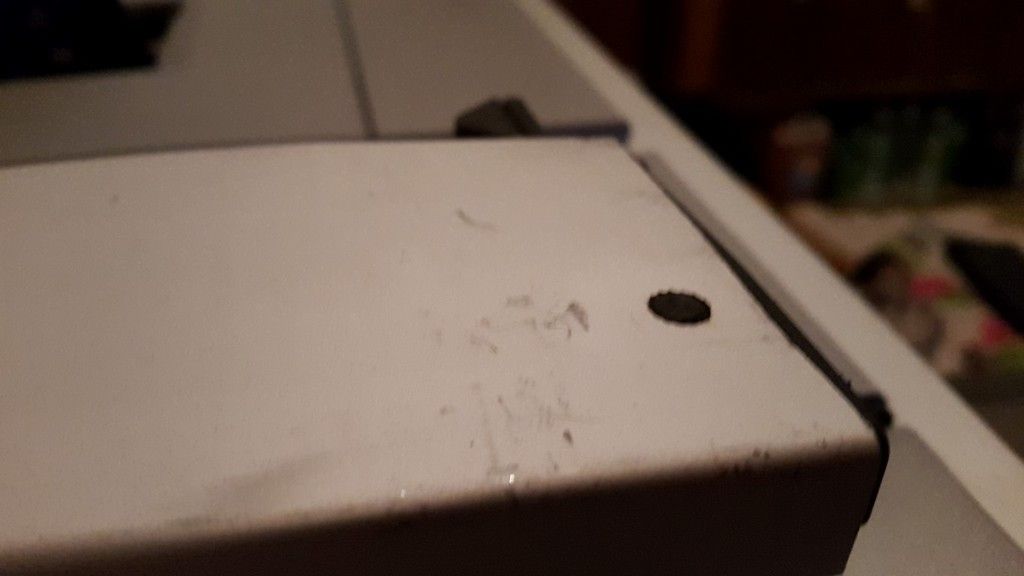

Finally I have disassembled everything now and I am thinking about how to improve the lift mechanism for the moment. What I also found is, that the main frame metal body at mine, is not painted and as I was watching today your photos again, I think as I can see, that yours is painted black! Dear transatlantic, can you confirm this? Mine has oil everywhere at the metal part and probably it needs painting, as if the oil will dry with the wood dust, it will become rusty. Did they forget to paint mine? Go figure!

Anyway, overall the motor seems powerful, the table seems solid, the plastic base and the metal stand also seems robust and if this saw was coming correctly aligned from the factory, it would be a nice choice. It seems to be a copy of the American Bosch 4100 table saw, as it has almost identical design, so that is good thing IMHO. If you are fan of DIY, Chinese always leave some homework for you with these cheap saws, but you must wish that this homework is easy to repair and not a malfunction that you can't fix it at all, so first you need to inspect it carefully and if you see that the castings or other important things seems straight, then if you have appetite, keep it and make it better.

A last note only, you must keep in mind that there is not any perfect Chinese cheap table saw (or other machines too), this is almost a rule! So don't search for the perfect one, but for the "I want become perfect" one.

PS: I will upload some pictures soon.

It might be a lot of money, but it isn't a lot of money for a Tablesaw unfortunately.Arvacon":16j5drve said:Yep that's right, it's a lot of money and I was expect at least something properly sealed.

Sometimes when I disappointed, I don't feel the appetite to argument with these kind of sellers. I sent them an email to take extra care about shipping and handling of this device and they answered me that everything will be as I requested and they will extra care about this. Bulls*#t!

I have seen a lot of times unscrewed screws at important parts in other machines, straight out of the box, so that's why I decided to dismantle it, as I trust more myself than the Chinese workers. It was not that hard, the only difficult was to remove the plastic base without unscrew the trunions, but if you remove it diagonally, it comes off finally.

You are lucky that they treated you with this way. Maybe I should try to contact with them now that I have calm down, but it's been more than 10 days that I have received it and maybe it is a little late to complain now.

I will make some improvements at high adjustment axis and I will try maybe to seal the gear parts from the dust, but we will see. The trunions have plenty of play, so you can adjust the blade's base. I will probably make a new topic about these improvements and I will upload photos when I will have make a progress.

Sorry for the full sized pictures that they made this post too long, but I tried to upload them at forum's server and it has not enough space. At the last photos you will see the metal base part that I was talking about, as it is bare metal without paint and with visible grinding marks from the factory.