swagman

Established Member

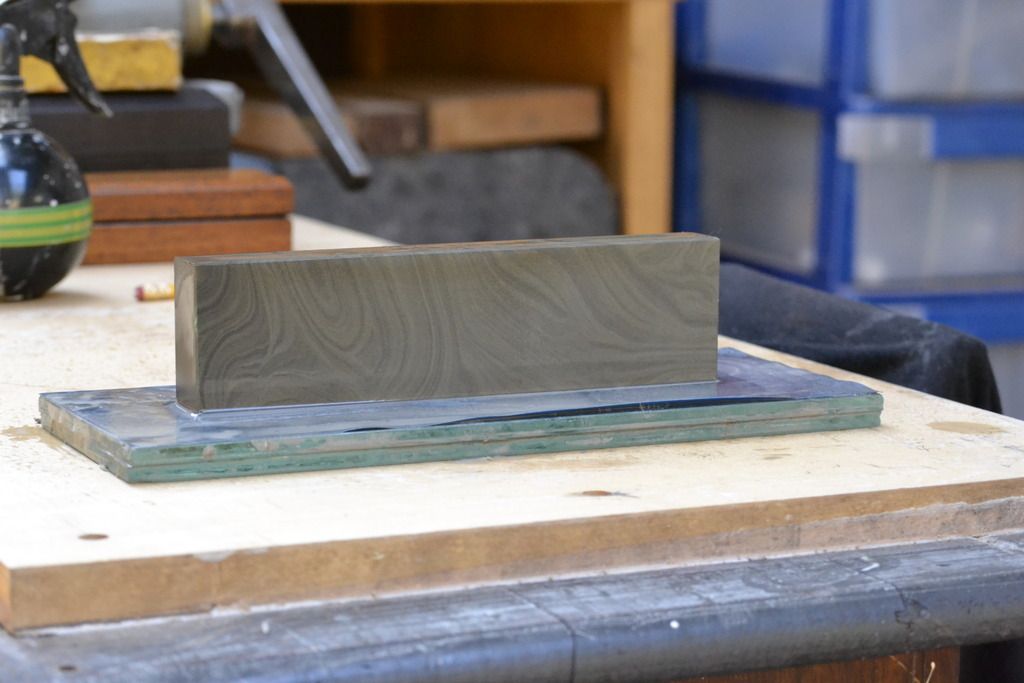

Another stone I recently purchased from the U.K. (Most likely the last honing stone I am going to purchase.)

The top surface of the stone showed no obvious signs to its origin.

But the underside was quite different, and the primary reason I chose to bid on this stone. The grain pattern indicated a natural stone, and not a man made stone.

Flat sanding with 220, followed by 400 grit w & d, highlighted it as being a quick release slurry stone, of a soft to medium hardness. The swirly grain pattern was now much more obvious to see after a light spray of water.

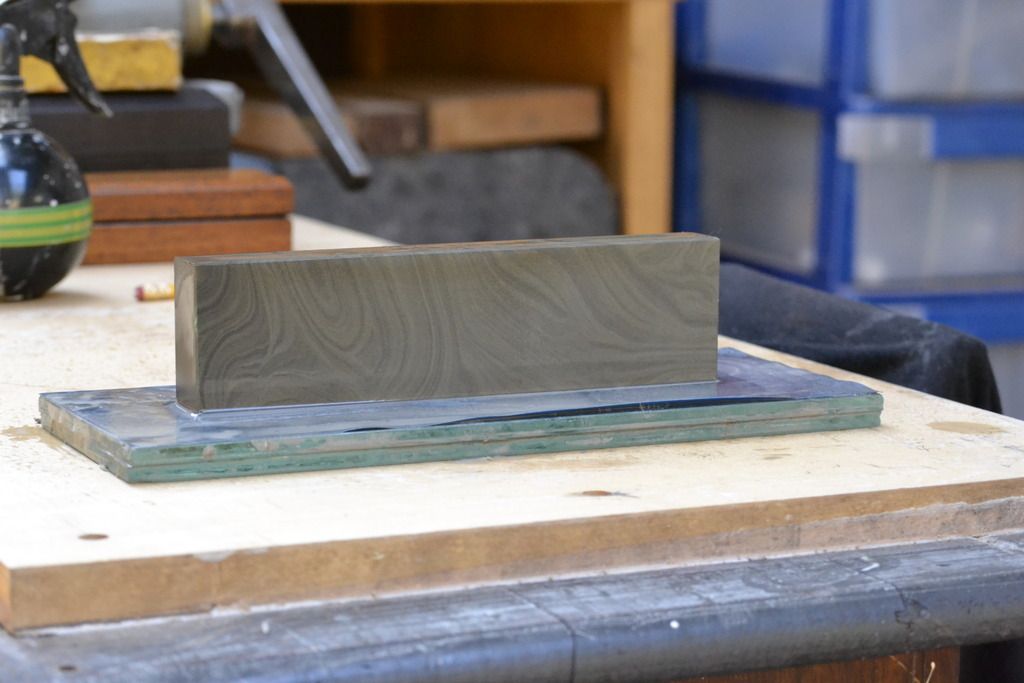

The next photo shows the sedimentary layering within the stones side grain.

Additional information;

Dimensions; 20.1 cm x 5.3 cm x 2.5 cm. (266 cm3)

Weight; 740 grams.

Specific Gravity (SF) = 2.78

Conclusion; the stone appears to be a highly featured Scotch Dalmore Blue. Possibly better suited to water as a lubricant than thin oil. A quick release slurry stone, suggesting a fast cutting stone. A high range in SF, indicating a large % of fine particles within its make up.

I would rate this as a high value/ high quality honing stone, purchased at a remarkably cheap price.

Stewie;

The top surface of the stone showed no obvious signs to its origin.

But the underside was quite different, and the primary reason I chose to bid on this stone. The grain pattern indicated a natural stone, and not a man made stone.

Flat sanding with 220, followed by 400 grit w & d, highlighted it as being a quick release slurry stone, of a soft to medium hardness. The swirly grain pattern was now much more obvious to see after a light spray of water.

The next photo shows the sedimentary layering within the stones side grain.

Additional information;

Dimensions; 20.1 cm x 5.3 cm x 2.5 cm. (266 cm3)

Weight; 740 grams.

Specific Gravity (SF) = 2.78

Conclusion; the stone appears to be a highly featured Scotch Dalmore Blue. Possibly better suited to water as a lubricant than thin oil. A quick release slurry stone, suggesting a fast cutting stone. A high range in SF, indicating a large % of fine particles within its make up.

I would rate this as a high value/ high quality honing stone, purchased at a remarkably cheap price.

Stewie;