motownmartin

Established Member

Gary":2vkdc3gg said:Is that table top not finished yet? :lol::lol:

:lol:

No, it's not even started

Martin

Gary":2vkdc3gg said:Is that table top not finished yet? :lol::lol:

:lol:

Martin I covered my top with a piece of this It's about three times thicker than formica type laminates, infact perfect for router table tops. It comes in many colours two sided, the colours of mine was white/cream one side and black marble on the other side. Because it is so thick it's flat to start with, just evo stick it to a piece of mdf and your done, no bumps and to cut it just use a router, dead easy. :lol:motownmartin":1ob7vpz8 said:Just realised that I had to throw it away as it got damp and bowed

Martin

Lord Nibbo":gzjrce49 said:Martin I covered my top with a piece of this It's about three times thicker than formica type laminates, infact perfect for router table tops. It comes in many colours two sided, the colours of mine was white/cream one side and black marble on the other side. Because it is so thick it's flat to start with, just evo stick it to a piece of mdf and your done, no bumps and to cut it just use a router, dead easy. :lol:motownmartin":gzjrce49 said:Just realised that I had to throw it away as it got damp and bowed

Martin

Thanks Niki, another option for me to think about.Niki":3kwbqntx said:Hi Martin

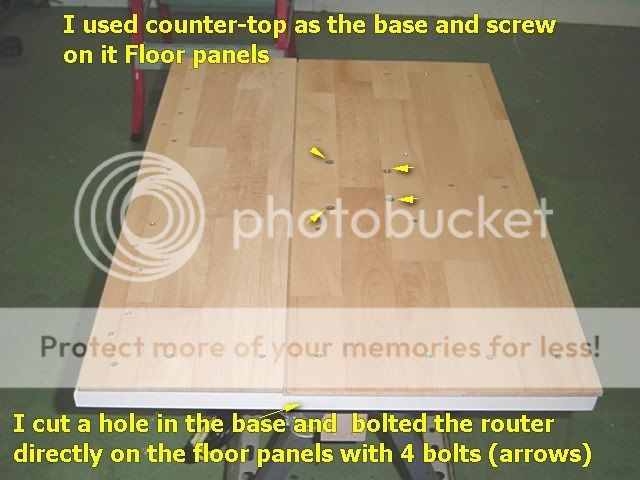

On my first router table I used 21mm plywood as a top and covered it with 8mm "floor panels" (Classen) that are laminated from both sides.

On the new one, I used 30mm counter top and also covered it with 8mm floor panels.

The floor panels are connected to the top with screws.

niki

motownmartin":36cvn7l6 said:Lord Nibbo":36cvn7l6 said:Martin I covered my top with a piece of this It's about three times thicker than formica type laminates, infact perfect for router table tops. It comes in many colours two sided, the colours of mine was white/cream one side and black marble on the other side. Because it is so thick it's flat to start with, just evo stick it to a piece of mdf and your done, no bumps and to cut it just use a router, dead easy. :lol:motownmartin":36cvn7l6 said:Just realised that I had to throw it away as it got damp and bowed

Martin

Thanks LN, seen this stuff in B&Q but wasn't sure about it, but if you have used it then it's good enough for me, how thick was the MDF you used :?:

Martin

I'm trying Tony, if you are good I might even let you come round and help me :lol: :wink:Tony":mkcg0lud said:Come on Martin, get it built :wink: :lol:

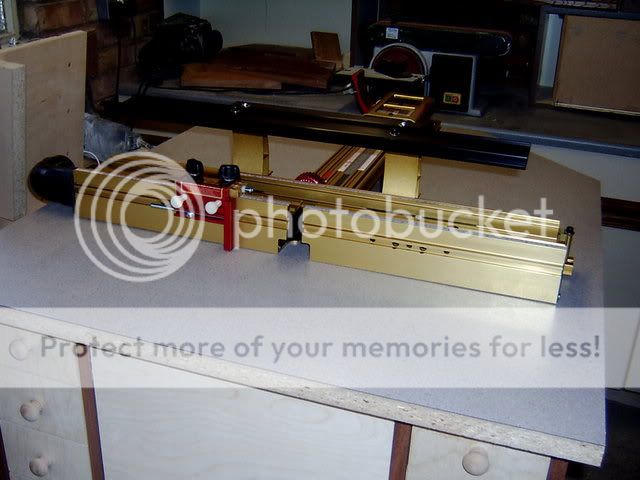

That's the top in the photo's, it'll be fine once I have waved the magic wand :lol:Gary":3kxuy7c2 said:Still got no top to attach it to though. :lol::lol:

:lol:

At this rate you problem will be solved when someone buys you one for christmas.

Mike.C":3iz0uqbv said:Very nice Martin, well done mate, it looks a right treat =D> =D> =D> =D> =D> =D>

Cheers

Mike

motownmartin":1sfsxq2b said:I'm trying Tony, if you are good I might even let you come round and help me :lol: :wink:Tony":1sfsxq2b said:Come on Martin, get it built :wink: :lol:

motownmartin":rny7t459 said:it doesn't look as good as Lord Nibbo's but not bad for a beginner

Lord Nibbo":2bg3m9g1 said:motownmartin":2bg3m9g1 said:it doesn't look as good as Lord Nibbo's but not bad for a beginner

Well it look ok to me =D> The only difference is I glued on the hardwood edges first, covered it all with the laminate then routered the edge of the laminate back to the hardwood, doing that way made it easier to glue on the laminate.

PS ... I used Evostick contact adhesive and put two coats on both surfaces.