Hi Guys, first real post here. So Ive always wanted a pair of high end wood finished speakers, they just look so nice imo, however I didnt want to pay the 1000s they usually cost.

So I have 2 pairs of mission M74 floor standing speakers which sound phenomenal but the vinyl wood effect didnt really tickle my fancy. It was a black effect and the speakers were knocked on the corners, not pretty overall but worth salvaging.

Never having dont any sort of wood work and researched and came across wood veneer. I wasnt worried about the species of the wood just that it had to be wood! So I found some cherry which wasnt too expensive and started work on my speakers.

20160417_212148 by joe blogggs, on Flickr

20160417_212148 by joe blogggs, on Flickr

All corners shaped

20160418_161513 by joe blogggs, on Flickr

20160418_161513 by joe blogggs, on Flickr

Then I first started sticking the veneer on with contact cement but this was proving to not be very economical with alot of cement used and the fact of once I set it down it was down for good. So I done some reading and came across the PVA and iron on method, so that was used the rest of the way. Then cut and sanded the veneer which ended up with this

20160802_180719 by joe blogggs, on Flickr

20160802_180719 by joe blogggs, on Flickr

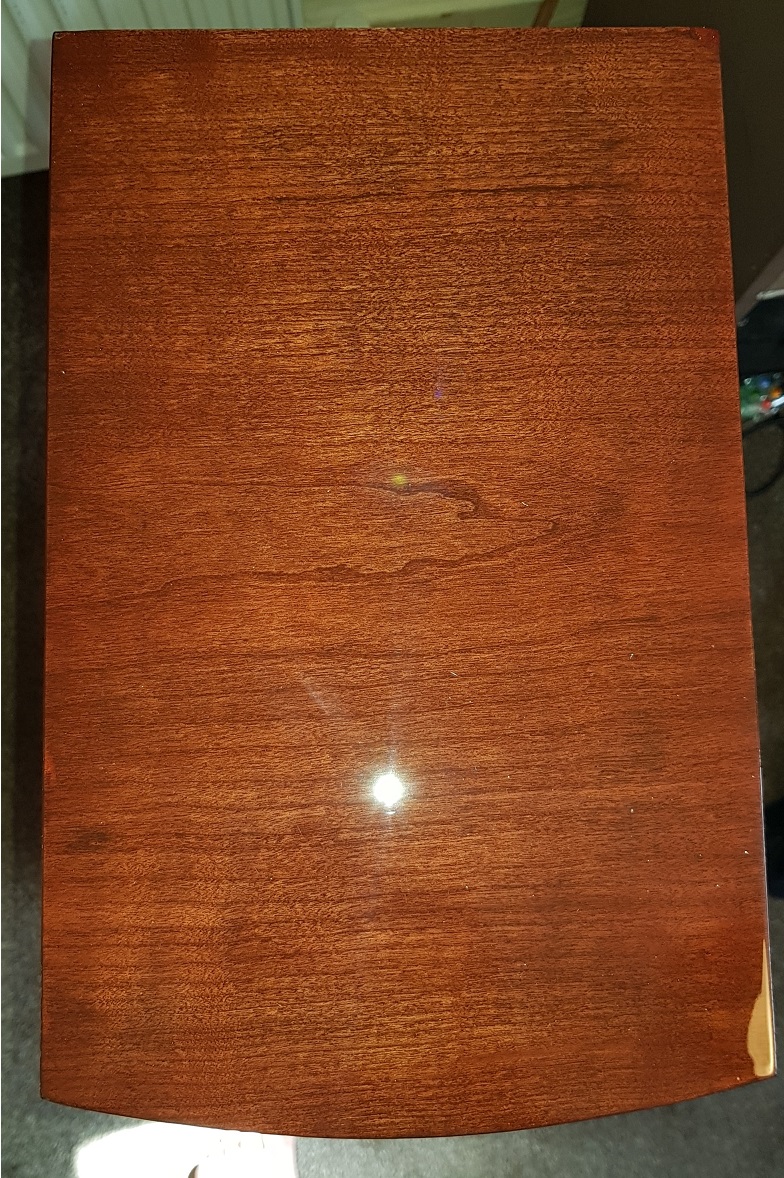

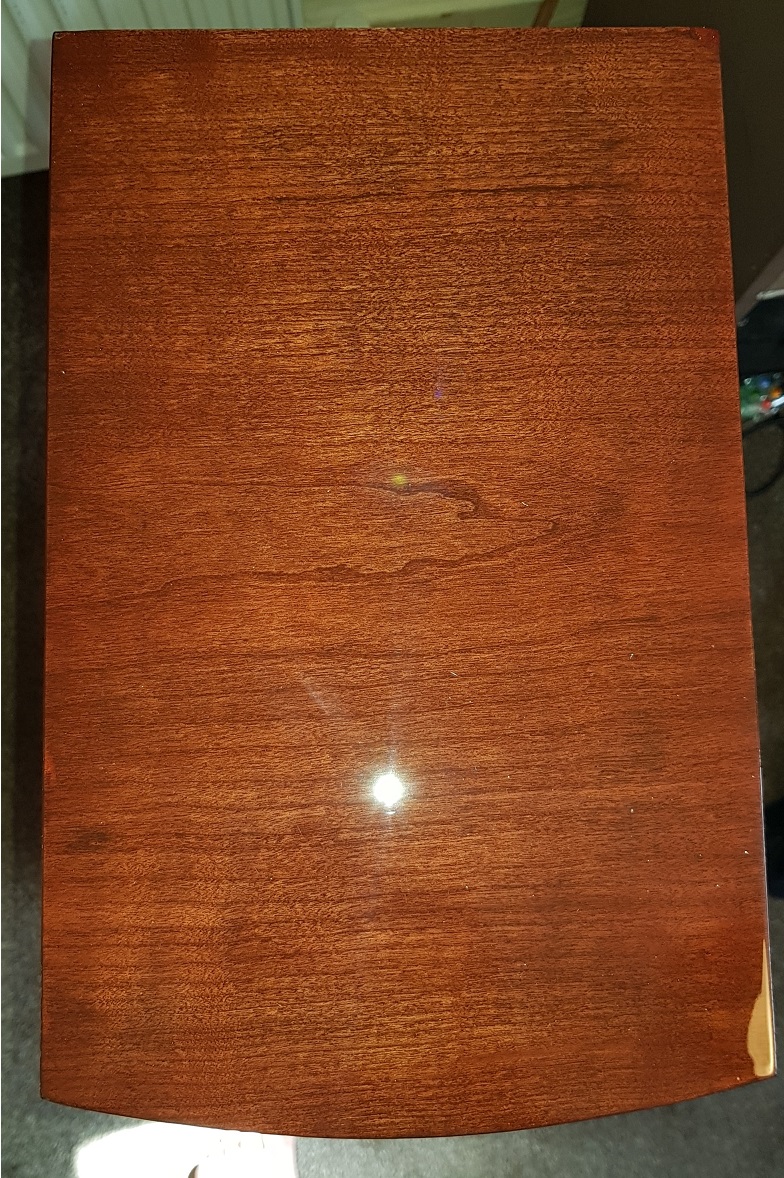

Now this was looking promising and I knew the colour of stain I wanted. However little did I know that cherry was supposed to be a porous and hard to stain wood with blochyness. So after more research I ended up ordering the General Finishes conditioner and rosewood gel stain. This worked really well and gave me no blochyness (atleast I couldnt see any, maybe you pros can?)

20160801_205744 by joe blogggs, on Flickr

20160801_205744 by joe blogggs, on Flickr

Now I wanted a high gloss finish. Knowing nothing about finishing wood to a high gloss finish, but being an enthusiast car detailer and car sprayer I though why not use 2k Automotive clear coat, its high build, high gloss, very hard wearing, UV resistant etc. So after 3 coats I ended up with a nice glossy albeit orange peely finish. Unfortunately no pictures of that but 3 days later I started flattening with 1500grit upto 3000 and started polishing.

Wetsanding testing

20170813_033046 by joe blogggs, on Flickr

20170813_033046 by joe blogggs, on Flickr

Then I used my car compounds and polishes to bring the finish to a high gloss, for any detailer that maybe here I used a Lake country purple foamed wool pad on rotary and Meguiars M101 cutting compound and finished with Carpro Reflect Finishing polish. Then coated with Bilt Hamber Double Speed Wax.

20170813_163336 by joe blogggs, on Flickr

20170813_163336 by joe blogggs, on Flickr

20170811_163349 by joe blogggs, on Flickr

20170811_163349 by joe blogggs, on Flickr

20170804_160027 by joe blogggs, on Flickr

20170804_160027 by joe blogggs, on Flickr

20170813_163405 by joe blogggs, on Flickr

20170813_163405 by joe blogggs, on Flickr

20170813_163303 by joe blogggs, on Flickr

20170813_163303 by joe blogggs, on Flickr

20170813_170326 by joe blogggs, on Flickr

20170813_170326 by joe blogggs, on Flickr

Thanks for reading if you got this far but I learned alot on this project and thoroughly enjoyed it, next time however If i do decide to veneer my other pair I will use peel and stick veneer for a smoother finish, unless you guys can recommend me something else?

So I have 2 pairs of mission M74 floor standing speakers which sound phenomenal but the vinyl wood effect didnt really tickle my fancy. It was a black effect and the speakers were knocked on the corners, not pretty overall but worth salvaging.

Never having dont any sort of wood work and researched and came across wood veneer. I wasnt worried about the species of the wood just that it had to be wood! So I found some cherry which wasnt too expensive and started work on my speakers.

20160417_212148 by joe blogggs, on Flickr

20160417_212148 by joe blogggs, on FlickrAll corners shaped

20160418_161513 by joe blogggs, on Flickr

20160418_161513 by joe blogggs, on FlickrThen I first started sticking the veneer on with contact cement but this was proving to not be very economical with alot of cement used and the fact of once I set it down it was down for good. So I done some reading and came across the PVA and iron on method, so that was used the rest of the way. Then cut and sanded the veneer which ended up with this

20160802_180719 by joe blogggs, on Flickr

20160802_180719 by joe blogggs, on FlickrNow this was looking promising and I knew the colour of stain I wanted. However little did I know that cherry was supposed to be a porous and hard to stain wood with blochyness. So after more research I ended up ordering the General Finishes conditioner and rosewood gel stain. This worked really well and gave me no blochyness (atleast I couldnt see any, maybe you pros can?)

20160801_205744 by joe blogggs, on Flickr

20160801_205744 by joe blogggs, on FlickrNow I wanted a high gloss finish. Knowing nothing about finishing wood to a high gloss finish, but being an enthusiast car detailer and car sprayer I though why not use 2k Automotive clear coat, its high build, high gloss, very hard wearing, UV resistant etc. So after 3 coats I ended up with a nice glossy albeit orange peely finish. Unfortunately no pictures of that but 3 days later I started flattening with 1500grit upto 3000 and started polishing.

Wetsanding testing

20170813_033046 by joe blogggs, on Flickr

20170813_033046 by joe blogggs, on FlickrThen I used my car compounds and polishes to bring the finish to a high gloss, for any detailer that maybe here I used a Lake country purple foamed wool pad on rotary and Meguiars M101 cutting compound and finished with Carpro Reflect Finishing polish. Then coated with Bilt Hamber Double Speed Wax.

20170813_163336 by joe blogggs, on Flickr

20170813_163336 by joe blogggs, on Flickr 20170811_163349 by joe blogggs, on Flickr

20170811_163349 by joe blogggs, on Flickr 20170804_160027 by joe blogggs, on Flickr

20170804_160027 by joe blogggs, on Flickr 20170813_163405 by joe blogggs, on Flickr

20170813_163405 by joe blogggs, on Flickr 20170813_163303 by joe blogggs, on Flickr

20170813_163303 by joe blogggs, on Flickr 20170813_170326 by joe blogggs, on Flickr

20170813_170326 by joe blogggs, on FlickrThanks for reading if you got this far but I learned alot on this project and thoroughly enjoyed it, next time however If i do decide to veneer my other pair I will use peel and stick veneer for a smoother finish, unless you guys can recommend me something else?