jimi43

Established Member

Today I decided to see if this old Marples steel was up to scratch...and so I set about sharpening the bevel.

Now there are probably as many views on how to sharpen bevels as there are chisels so I won't go into the best way of doing this...rather just show how I choose to do it and the results.

After roughing out the bevel on the side of the Tormek...just rolling it flat...I polished it on a flat piece of MDF with some MAAS as the abrasive.

Then for the important bit...the inside of the gouge. I have been meaning to find a suitable candidate to test a new honing idea I picked up from the Sweeney Todd brigade...that is using the powder from a hone flattening session to create a lapping paste. I came up with this kit:

Using the theory that any old carrier fluid/paste will do I chose Baby Oil because it was handy (and as others say, smells nice!). I placed a pinch of powder into the gouge near the edge...added a few drops of oil to the (suitably sized) dowel and mated the two....

Rubbing back and forth whilst taking care to keep the dowel flat created a very sharp edge indeed.

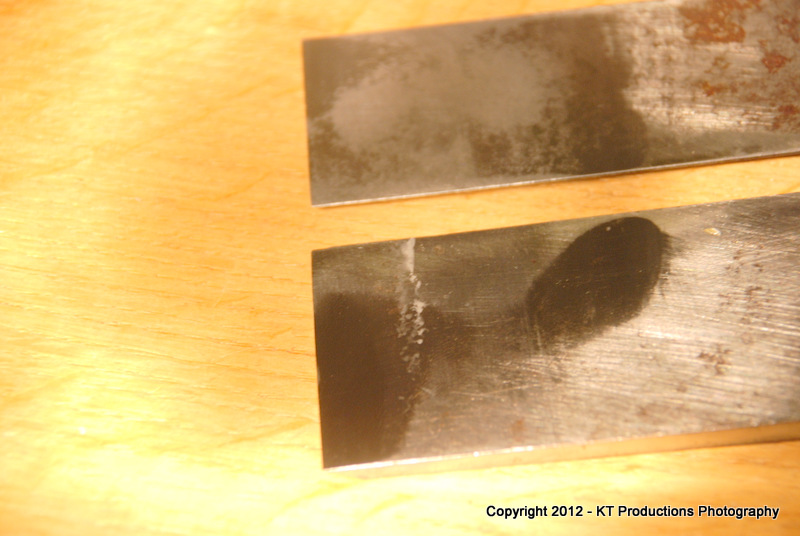

You can just see the highly polished band here:

...and following two pencil lines, the gouge made a nice job of this softwood. It was very controllable and needed just hand pressure...no tapping at all....

I'll test it on some hardwood but I have no doubt that it will be fine. After this workout, the edge was just as sharp and so holds up well.

Jim

Now there are probably as many views on how to sharpen bevels as there are chisels so I won't go into the best way of doing this...rather just show how I choose to do it and the results.

After roughing out the bevel on the side of the Tormek...just rolling it flat...I polished it on a flat piece of MDF with some MAAS as the abrasive.

Then for the important bit...the inside of the gouge. I have been meaning to find a suitable candidate to test a new honing idea I picked up from the Sweeney Todd brigade...that is using the powder from a hone flattening session to create a lapping paste. I came up with this kit:

Using the theory that any old carrier fluid/paste will do I chose Baby Oil because it was handy (and as others say, smells nice!). I placed a pinch of powder into the gouge near the edge...added a few drops of oil to the (suitably sized) dowel and mated the two....

Rubbing back and forth whilst taking care to keep the dowel flat created a very sharp edge indeed.

You can just see the highly polished band here:

...and following two pencil lines, the gouge made a nice job of this softwood. It was very controllable and needed just hand pressure...no tapping at all....

I'll test it on some hardwood but I have no doubt that it will be fine. After this workout, the edge was just as sharp and so holds up well.

Jim