Estoril-5

Established Member

Hi guys,

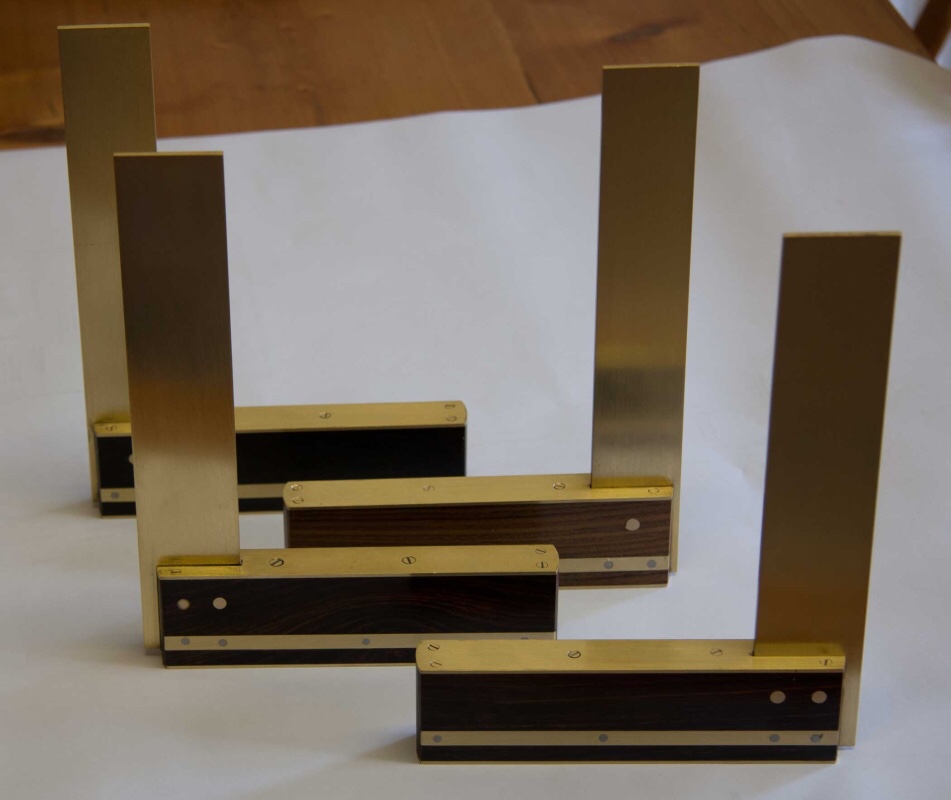

One basic hand tool that I'm lacking (well one with any accuracy) is a engineers or try square.

Marking out timber assuming it was square has landed to issues further down the build process.

Now I understand you get what you pay for, so;

1. how much do you spend to get a reasonable square, and

2. Is a square the right tool or do I need a t square or sliding bevel or something else.

Cheers guys

Sent from my Moto G (4) using Tapatalk

One basic hand tool that I'm lacking (well one with any accuracy) is a engineers or try square.

Marking out timber assuming it was square has landed to issues further down the build process.

Now I understand you get what you pay for, so;

1. how much do you spend to get a reasonable square, and

2. Is a square the right tool or do I need a t square or sliding bevel or something else.

Cheers guys

Sent from my Moto G (4) using Tapatalk