that's absolutely gorgeousFinally finished my first ever piece of furniture using English brown oak and American black walnut. Can't take any credit for the design other than the custom drawer pulls given it comes from https://www.foureyesfurniture.com/. Definitely not covered in clutter already.

View attachment 192167 View attachment 192166 View attachment 192165

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post a photo of the last thing you made

- Thread starter DTR

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

duke

Established Member

Very nice look, functional and not to imposing.Finally finished my first ever piece of furniture using English brown oak and American black walnut. Can't take any credit for the design other than the custom drawer pulls given it comes from https://www.foureyesfurniture.com/. Definitely not covered in clutter already.

View attachment 192167 View attachment 192166 View attachment 192165

Blackswanwood

Still Learning

Keepsake box made from ABW and Red Cedar. The inlay is Snakewood and the lining Sycamore. SmartButt hinges used with avoids the ugliness of a square knuckle.

Doug B

Shy Tot

This was my HVLP set up when I first got an Oneida super dust deputy.

I rigged it up to my extractor like this as I figured it would be for the quickest & that it would be handy to keep it mobile on the existing wheeled base.

In the nearly 3 years since I did this I’ve not move it once so clearly mobility wasn’t a necessity, also as expected I experienced quite a reduction in suction not only because of adding the cyclone (which I was expecting) but also the extra pipe & bends I used to keep it fitted to the original base.

so clearly mobility wasn’t a necessity, also as expected I experienced quite a reduction in suction not only because of adding the cyclone (which I was expecting) but also the extra pipe & bends I used to keep it fitted to the original base.

My intention with re-jigging things was to reduce the pipework & by doing so increase the suction from its current 57% efficiency when measured against the impeller on its own.

First off I wanted to get as long & straight a piece of 5” spiral duct as I could to the cyclone as this is beneficial for the cyclone to work effectively, although I had to incorporate a 45 degree bend on the inlet that is followed by a 2.8m piece of ducting that runs to roughly the centre point of the long workshop wall. From there the duct drops to the floor & a piece of flexible pipe is attached to it long enough to reach all of my machines, in doing this I’ve halved the amount of 5” flexible ducting I had on the system.

A piece of 3/4” ply was fixed to the wall & floor then braced at the top onto which the impeller unit was bolted.

I built a simple unit for the fine filter to sit on the added bonus being it gave me some much needed storage space for a couple of systainers.

The streamlining of the system has taken it up to 72% efficiency a gain of 15% which I really pleased with as a fine filter & cyclone are always going to take a toll.

But the real proof as they say is in the pudding & on Thursday it got it first real workout & performed admirably

I rigged it up to my extractor like this as I figured it would be for the quickest & that it would be handy to keep it mobile on the existing wheeled base.

In the nearly 3 years since I did this I’ve not move it once

My intention with re-jigging things was to reduce the pipework & by doing so increase the suction from its current 57% efficiency when measured against the impeller on its own.

First off I wanted to get as long & straight a piece of 5” spiral duct as I could to the cyclone as this is beneficial for the cyclone to work effectively, although I had to incorporate a 45 degree bend on the inlet that is followed by a 2.8m piece of ducting that runs to roughly the centre point of the long workshop wall. From there the duct drops to the floor & a piece of flexible pipe is attached to it long enough to reach all of my machines, in doing this I’ve halved the amount of 5” flexible ducting I had on the system.

A piece of 3/4” ply was fixed to the wall & floor then braced at the top onto which the impeller unit was bolted.

I built a simple unit for the fine filter to sit on the added bonus being it gave me some much needed storage space for a couple of systainers.

The streamlining of the system has taken it up to 72% efficiency a gain of 15% which I really pleased with as a fine filter & cyclone are always going to take a toll.

But the real proof as they say is in the pudding & on Thursday it got it first real workout & performed admirably

Last edited:

duke

Established Member

Well that's a very good improvement to your dust control system, nice tidy modification and as you say, more storage is available.

duke

Established Member

My monstrosity uses up four times more room than yours.

£400.66

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Qwikfast Trade & DIY Supplies Limited

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£96.66

£101.95

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router

Amazon US

£30.95

£40.82

Tracer ProScribe Tool with Deep Hole Pencil, Lead Holster and Carry Case (DIY, Woodworking, and Carpentry Multi-Function Scribe Tool)

Build and Plumb Materials Online

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

robgul

Barry Bucknell is my hero

duke

Established Member

My monstrosity uses up four times more room than yours.

Blimey that dust extraction would take up most of my working space

duke

Established Member

I'm fortunate to have the space. It's a storage bay which is behind a set of doors, not in the actual shop. Helps minimize the noise.

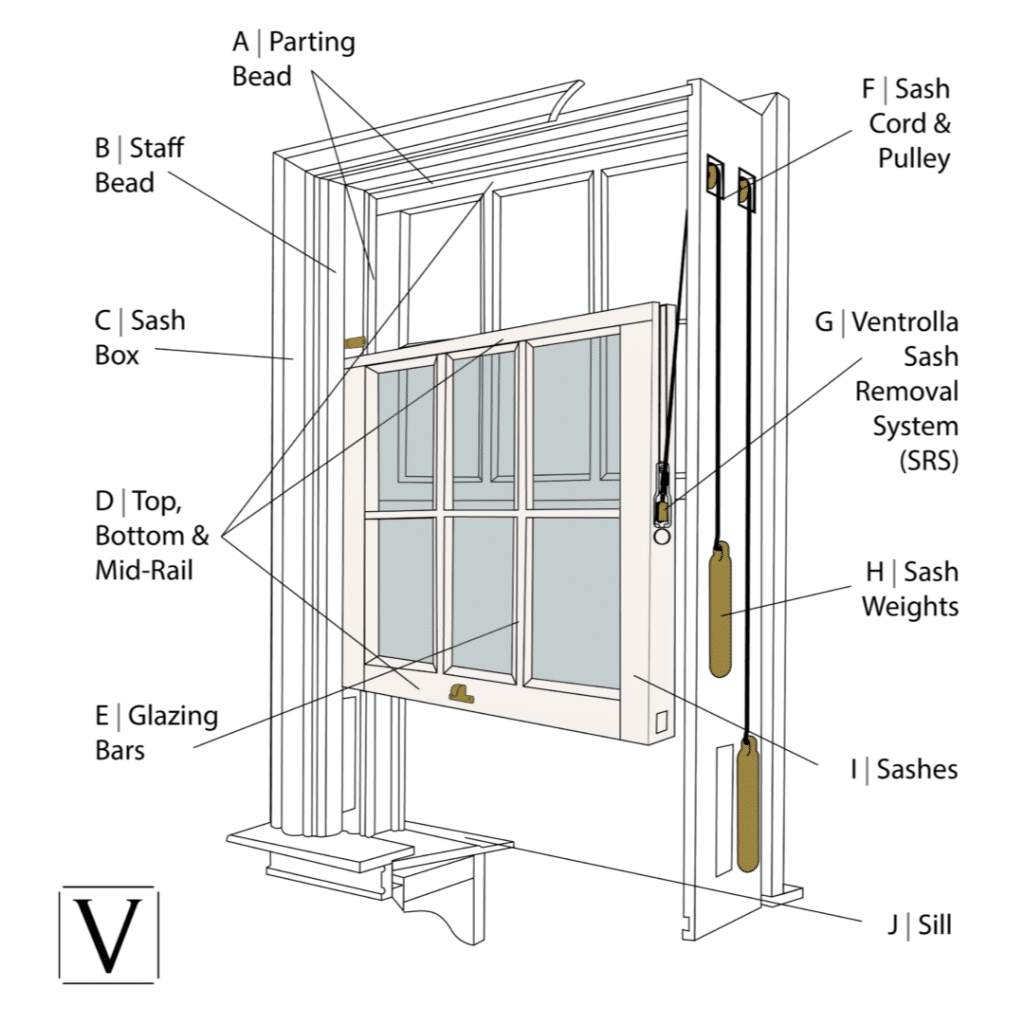

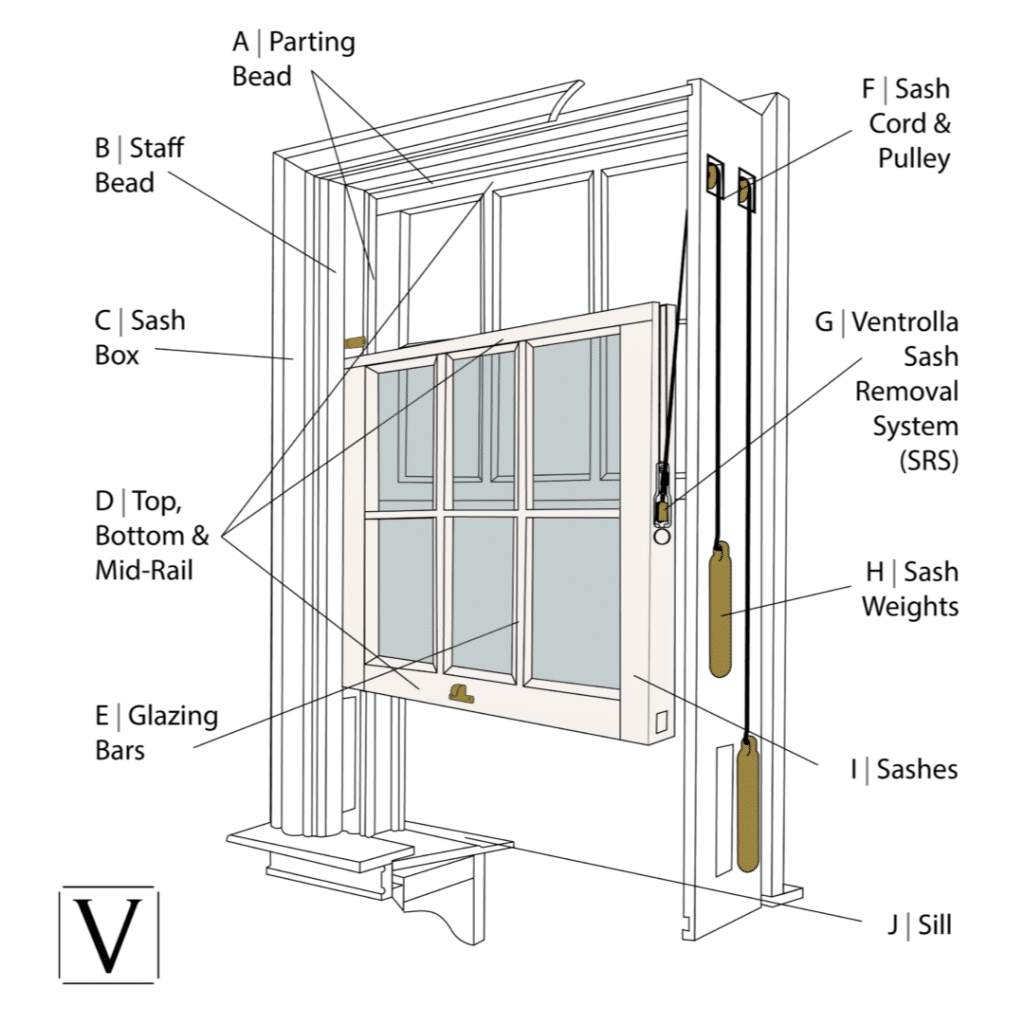

Having fixed up the router table and resigned myself that a spindle moulder will be in my future I’ve been cracking on with the sash window.

Worked out the parting bead slot and the spiral balance slots and covers.

I’m going to finish the slots above the sill to attempt to avoid/minimise water ingress points.

I was not confident with the saw down the side and bash out the pocket method, so I resorted to routing out the pockets and making covers for them.

Pulley recesses were also done with a router and template. The cordless palm router is my best friend.

Then I machined up all the staff and parting beads and the sill and head linings, as well as a couple of boards for secret Santa!

Sorry could get images in with the text, no idea why but they’re all petty obvious!

Fitz

Worked out the parting bead slot and the spiral balance slots and covers.

I’m going to finish the slots above the sill to attempt to avoid/minimise water ingress points.

I was not confident with the saw down the side and bash out the pocket method, so I resorted to routing out the pockets and making covers for them.

Pulley recesses were also done with a router and template. The cordless palm router is my best friend.

Then I machined up all the staff and parting beads and the sill and head linings, as well as a couple of boards for secret Santa!

Sorry could get images in with the text, no idea why but they’re all petty obvious!

Fitz

duke

Established Member

Fitz , what are the shiny brass thingys were the windows run ? I think I know the answer but not sure.Having fixed up the router table and resigned myself that a spindle moulder will be in my future I’ve been cracking on with the sash window.

Worked out the parting bead slot and the spiral balance slots and covers.

I’m going to finish the slots above the sill to attempt to avoid/minimise water ingress points.

I was not confident with the saw down the side and bash out the pocket method, so I resorted to routing out the pockets and making covers for them.

Pulley recesses were also done with a router and template. The cordless palm router is my best friend.

Then I machined up all the staff and parting beads and the sill and head linings, as well as a couple of boards for secret Santa!

Sorry could get images in with the text, no idea why but they’re all petty obvious!

Fitz

View attachment 192305

View attachment 192306

View attachment 192307

View attachment 192308

View attachment 192309

View attachment 192310

View attachment 192311

They are pulleys that the sash cord runs over, the window sashes are counterweighted so that they are balanced. The image below (credit Ventrolla) shows how the overall window works.Fitz , what are the shiny brass thingys were the windows run ? I think I know the answer but not sure.

It’s nice to see someone who can still make those windows so very well done

Hiya all

duke

Established Member

I see now, looking back at the pic didn't notice it was a pulley, time to get new glasses.They are pulleys that the sash cord runs over, the window sashes are counterweighted so that they are balanced. The image below (credit Ventrolla) shows how the overall window works.

Bumble

Established Member

Another box (same Japanese cedar construction waste stock); practice makes a slightly better box than the previous. Sometimes.

This time joined two pieces to make the base for a wider box (three pieces for the lid as I cut the sides short by two millimetres), reduced thickness to eight millimetres from ten and figured out that a sharper pencil helps to make better cuts for joints!

Another forty two metres of stock left...

I would like to do another round of chisel/plane sharpening now but minus two degrees C (about twenty eight degrees in old money) is quite prickly on the hands for water stones...

This time joined two pieces to make the base for a wider box (three pieces for the lid as I cut the sides short by two millimetres), reduced thickness to eight millimetres from ten and figured out that a sharper pencil helps to make better cuts for joints!

Another forty two metres of stock left...

I would like to do another round of chisel/plane sharpening now but minus two degrees C (about twenty eight degrees in old money) is quite prickly on the hands for water stones...

Nice box,

ozzpoz

Established Member

Spent the day making my 2nd set of coasters. Definitely better than my 1st set. And a wine gift box for a Christmas pressies. Made form yellow ceder. Smells great. Just not sure how to finish it. Or just leave it as it is.

Attachments

Similar threads

- Replies

- 1K

- Views

- 113K

- Replies

- 7

- Views

- 2K