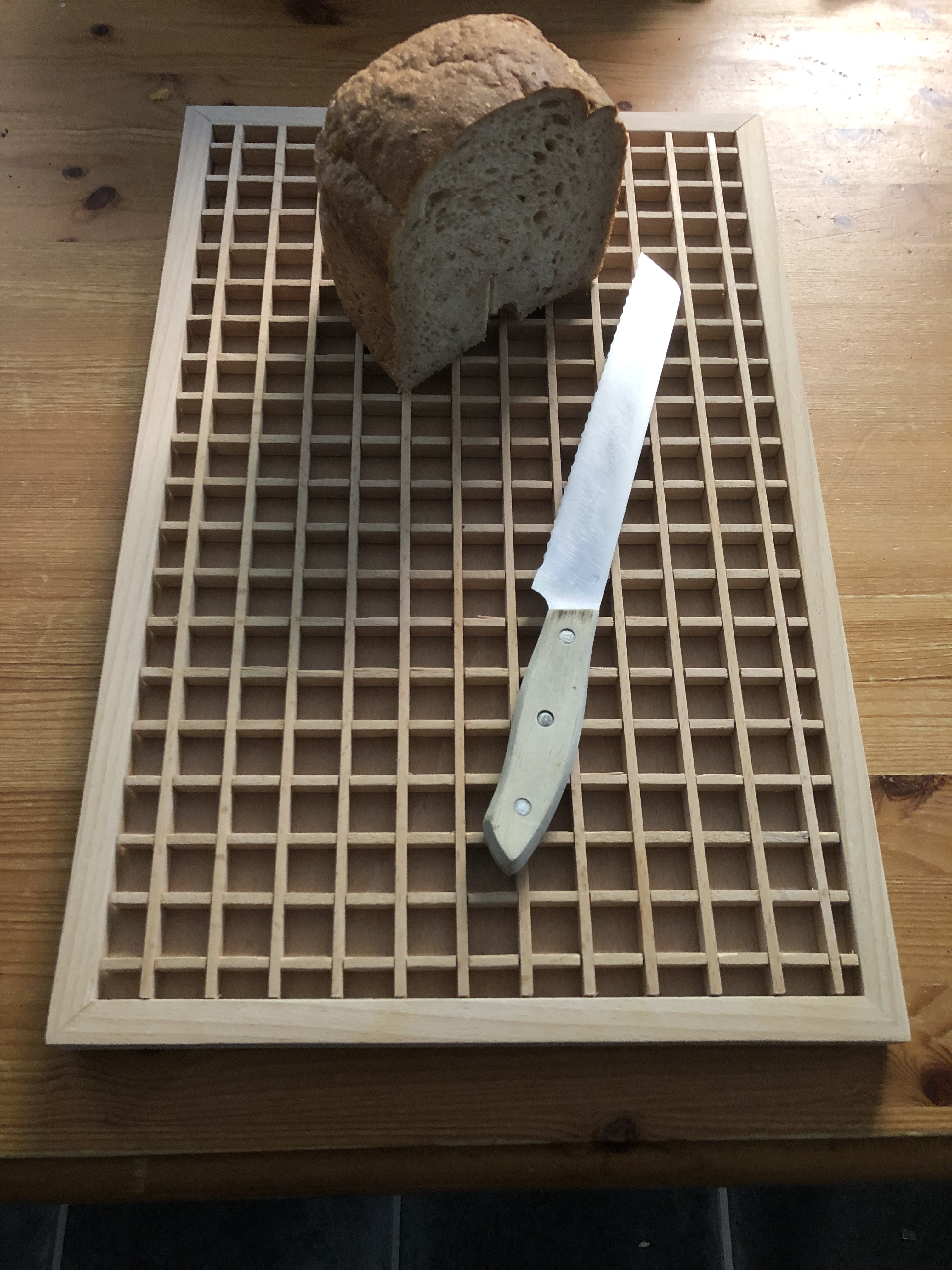

I love crusty bread , but the crumbs go everywhere when I cut it, so I decided to make a breadboard that catches the crumbs as I cut the bread. Beech with a beech faced ply base. The grid is jointed using half lap joints. The grid lifts out for emptying the crumbs.

Not so thick Mike.

That's a great idea.

I'm going to steal it BTW.