eoinsgaff

Established Member

Alf, perfect deduction. I found Cosman a good start but I hope to be able to change his method to suit my technique as I progress. I'm saving the saw dust from the dovetail cutting in case of an emergency...

Andy, that would have been the sound approach but I'm hell bent on using only glass on the door.

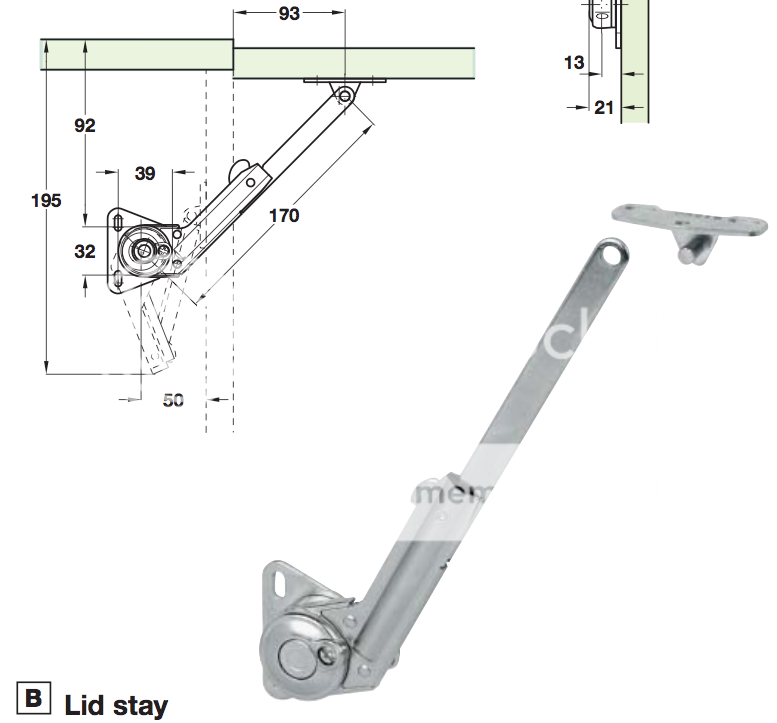

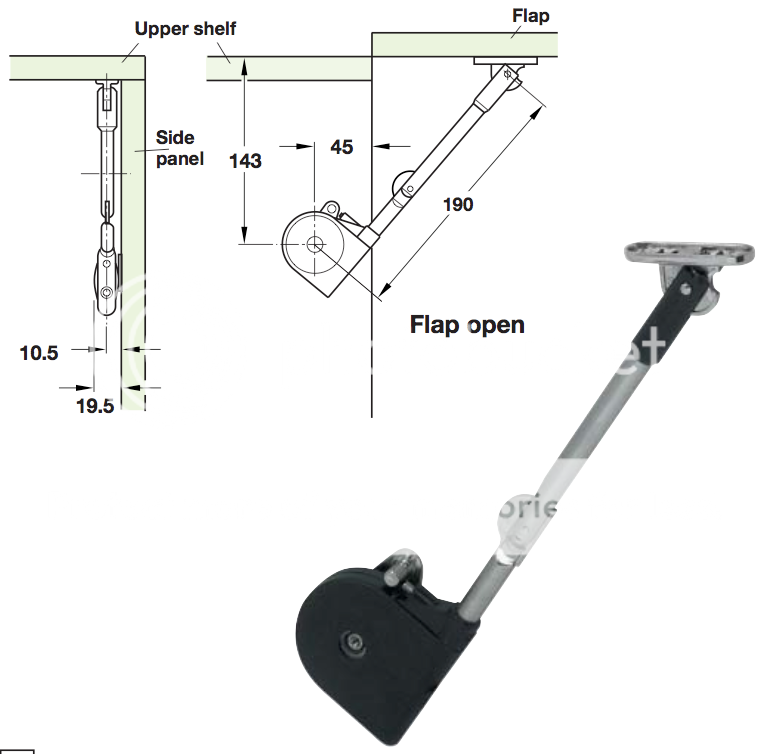

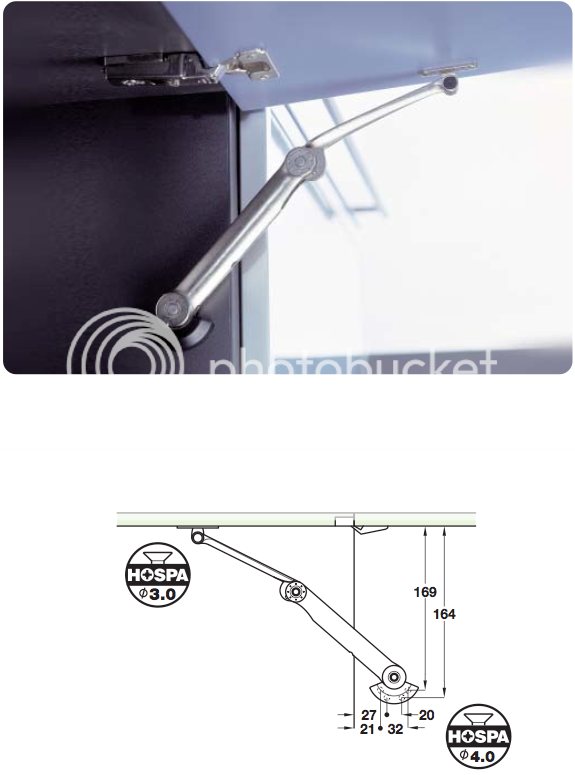

I've seen a type of hinge for glass thats almost identical to the standard kitchen door hinges. The glass would need to be drilled however. There's a cheap and reasonably common type of 'catch' for vertical kitchen doors. I don't know the name of it but its basically a bar that holds the door open and then a little push up releases the vertical door. Does this sound familiar to anyone and would it work? I've been looking on Issac Lord and a few other sites but I can't find it.

As an aside, any other Wallander fans out there?

Andy, that would have been the sound approach but I'm hell bent on using only glass on the door.

I've seen a type of hinge for glass thats almost identical to the standard kitchen door hinges. The glass would need to be drilled however. There's a cheap and reasonably common type of 'catch' for vertical kitchen doors. I don't know the name of it but its basically a bar that holds the door open and then a little push up releases the vertical door. Does this sound familiar to anyone and would it work? I've been looking on Issac Lord and a few other sites but I can't find it.

As an aside, any other Wallander fans out there?