Got my 6mm grooving cutter for the spindle moulder, and had an hour to spare this afternoon so decided to get the grooves cut in all the top, bottom and side panels to receive the back panels.

I've never used a spindle moulder before this year and I took advantage of Brad's offer to show me some basic usage. I also bought a DVD from Axminster, which was very instructional, but made me laugh as the presenter was an old timer (and the DVD was made in 1989!) and he kept on referring to the "Cockpit Drill" of the safety checks to go through before pressing start on the machine. It was funny, but it stuck with me.

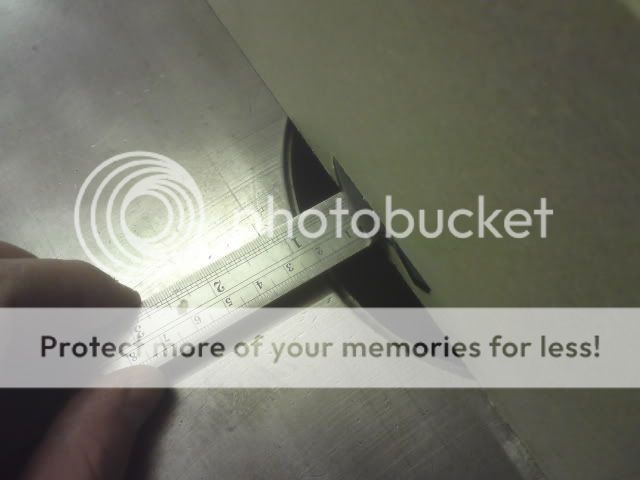

Anyway, the grooving cutter was installed and the spindle set at the correct height. I then attached a couple of MDF fences to the ali fences, and the attached a sacrificial piece of 6mm MDF.

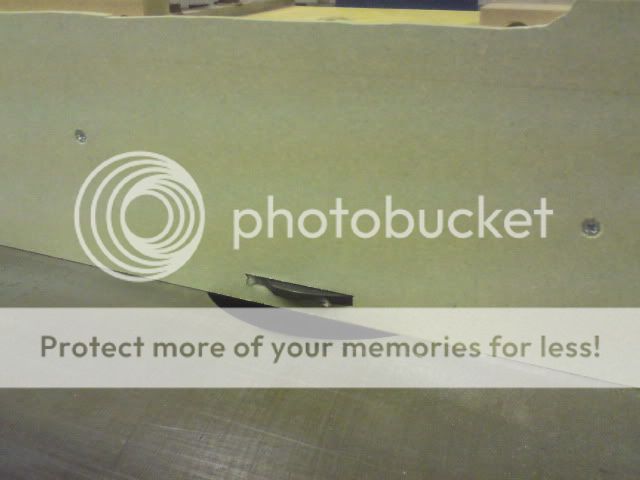

The fence locking mechanisms are then released and the machine started up. The whole fence arrangement is then slid back onto the rotating blade. The cutter cuts through the sacrificial fence and the machine turned off when the correct cutting depth is achieved - in this case 6mm.

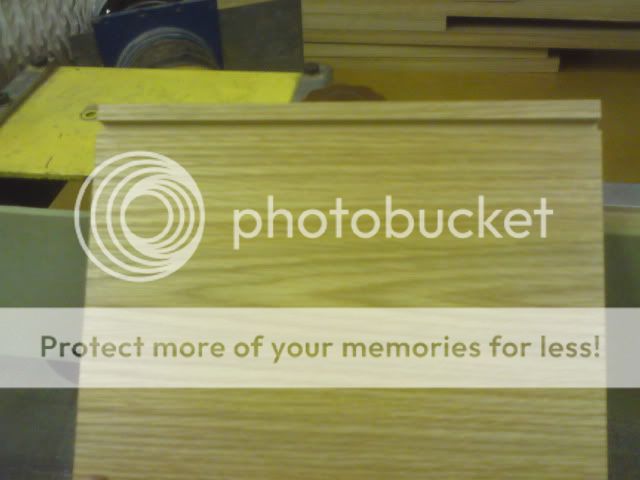

All the panels were then run over the blade, resulting in a nice clean groove and a tight fitting panel.

Tomorrow i'm going to size up all back panels and start on the finishing.

Another hour today brings total project time to date to 14 hours.

Cheers

Karl