Right now I am not sure about the very old American Stanleys with the thinner castings, but on everything made in the UK, Jacob is right. The sole provides valuable support to the blade. Way back, I had a similar discussion with Jacob, even tried to "prove" him wrong with some trigonometrics, but I made the same mistake you are making. The edge isn't touching the wood in your example.

Morfa, the Stanleys are not very prone to clogging, unless there is a problem with the fitting of the chipbreaker to the blade. Moving it 2mm out of the way does indeed "cure" the problem, but you loose all valuable effects from the chipbreaker. First it supports the edge (which isn't a bad idea with the thin Stanley blades) and second it won't help you to break the chips in order to prevent tearout.

Now, first you should decide how you want to use the plane. is it going to be a roughing tool, a big jack plane so to speak? The 5 1/2 is very heavy and wide for this task, but it can be used as a foreplane to flatten panels after a jack. In that case add a camber about 10" to 12" radius to the edge. I you want to use it as a jackplane, add a camber about 8". In both cases the chipbreaker isn't much help to break chips, but it can still help to stabilise the edge, so don't move it too far away.

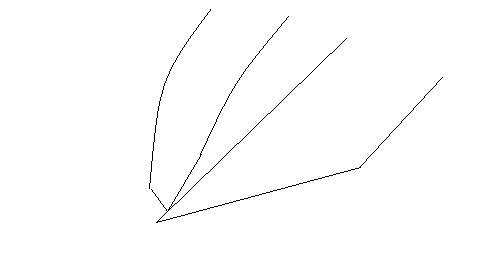

If you want to take thin shavings with this plane, like a smoother (or if you want to learn something for your nr. 4) then you will have to prepare your chipbreaker with much more care. First it should sit flat over the entire width of the blade. No light visible through the gap! Most any old plane I get is defective in this department and it really makes your plane clogging. I would also make sure your jack, fore and jointer is repaired in this area, beacuse it it so important to prevent clogging. Also make sure the edge of the chipbreaker ends in a rather sharp edge with some relieve behind it, like in this picture:

[/URL]

In this picture you can see something else, a small steep front bevel. It really should be small, I've seen 0.2 to 0.3 mm mentioned. This is optional! But it improves the chipbreaker's ability to break the chips. In order to actually break the chips it should be set very very close to the edge, just a bit more then shaving thickness. Especially on smoothers and jointers. On a jack or a foreplane it can be a bit further away.

Closing the mouth helps to avoid tearout, but only when it is very tight, just open enough to pass the shaving. You loose the support of the blade from the sole of the plane, and the little helpfull steep part on the front of the chipbreaker gets in the way. And more important, when you learn how to use the chipbreaker, you don't need a tight mouth. So, if you really, really, really want a tight mouth, then by all means, set the mouth tight. But know that you don't really need it so tight and it has adverse effects too.