No. This is one of the reasons why I have to be really careful online, because people can take the detail and erroneously apply it to an extension, where it would be non-compliant. This applies only to non-controllable outbuildings, and it is critical that the upper part of the slab is above ground. The DPM here is really only helping the inner part of the slab, and the outer edges dry off by being exposed. The difficulty of trying to protect a path for a continuous DPM/ DPC in a simple outbuilding is just too much. Exposed polythene is very susceptible to UV and physical damage, and would last 5 minutes if dressed up around the edge of the slab and built in under the bricks.

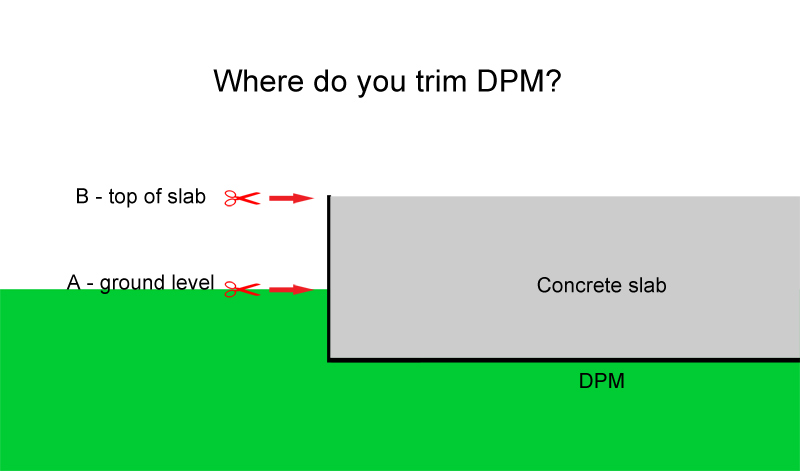

If you dress the DPM upwards at any point (your A or B) then water running down the face of the concrete would be trapped between the plastic and the concrete. Better to let that water go to ground, and for the edge of the slab to dry by being exposed. It's a compromise that works well, but which depends entirely on the slab being partly above ground.