seanybaby

Established Member

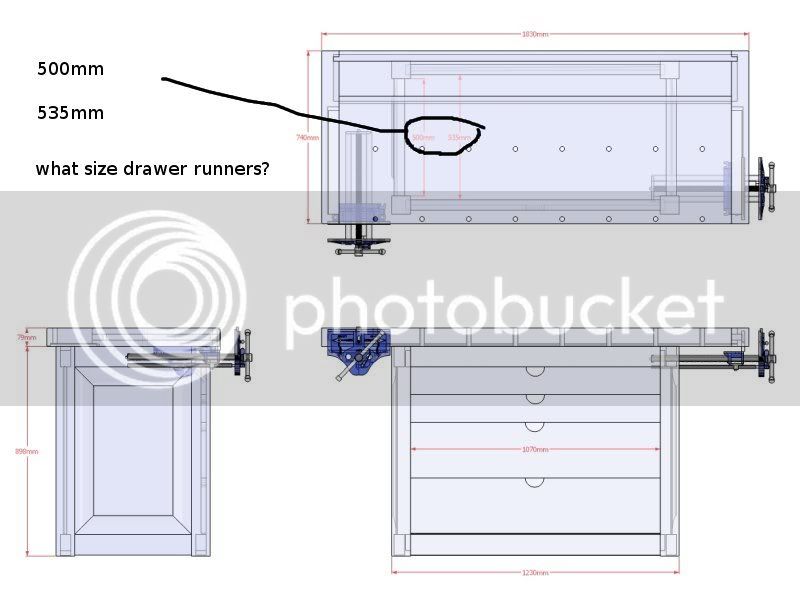

I thought i'd finished the designing bit of my bench, clearly i hadn't thought enough about it. :lol: Plus you lot keep giving me great suggestions.

I can see the advantages of having a bigger stand and also disadvantages of wide drawers.

From the points mentioned, i think i will have to go for half drawers and a cupboard. I can't afford to have more drawers than that.

I just have to work out how to do this incorporating the K/D construction techniques. Originally i was to go for bolts to connect the long rails to end pieces. Now i will need a partition in the middle for the drawer runners to attach to.

For the drawer runners do these from screwfix seem ok? http://www.screwfix.com/prods/19672.../Drawer-Fittings/Side-Fix-Drawer-Runner-450mm

My inside measurement for the drawers is about 500mm so do i go for the 450mm or 400mm runners?

I can see the advantages of having a bigger stand and also disadvantages of wide drawers.

From the points mentioned, i think i will have to go for half drawers and a cupboard. I can't afford to have more drawers than that.

I just have to work out how to do this incorporating the K/D construction techniques. Originally i was to go for bolts to connect the long rails to end pieces. Now i will need a partition in the middle for the drawer runners to attach to.

For the drawer runners do these from screwfix seem ok? http://www.screwfix.com/prods/19672.../Drawer-Fittings/Side-Fix-Drawer-Runner-450mm

My inside measurement for the drawers is about 500mm so do i go for the 450mm or 400mm runners?