Well I haven't had the call to 'pick me up from the airport' yet so I have done some more...

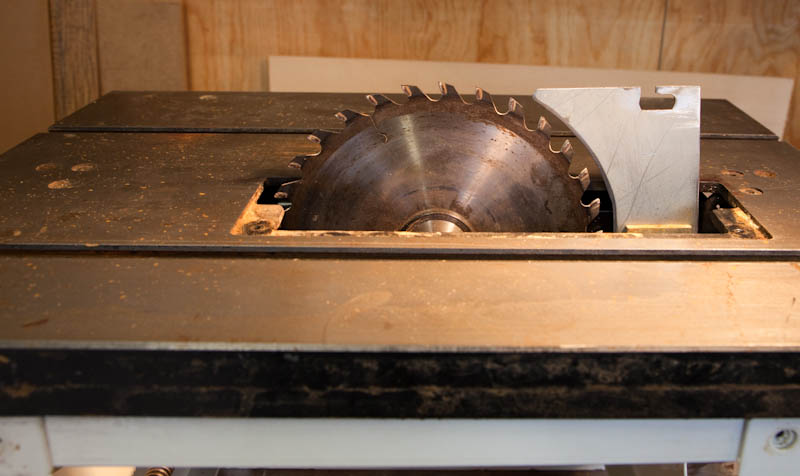

Made a 0.7 thick steel shim and fitted my riving knife. It lines up perfectly with the blade.

Lowered position

So moving on to blade alignment...

Now I thought this was going to be a bit of a pain but it turned out to be quite straightforward.

Putting a straight edge to the blade I could see it was out. Compare how much screw is showing at 80mm and 480mm on the rule -

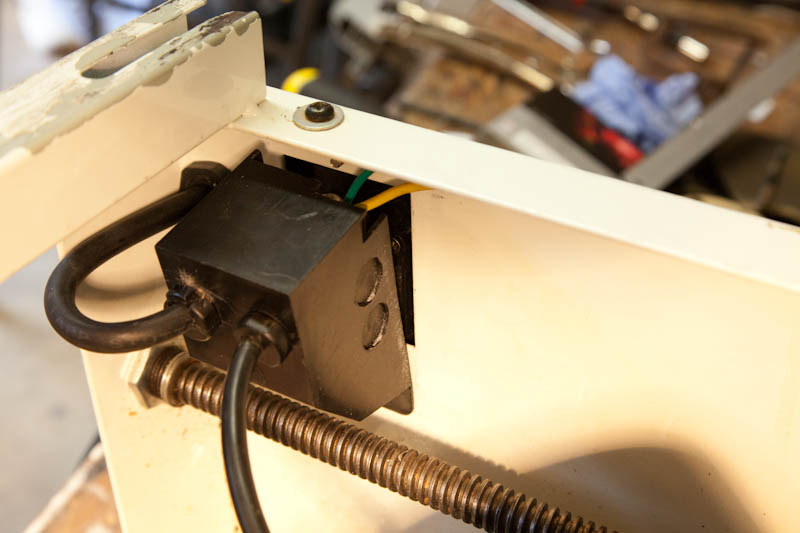

There are zinc plated steel hinge blocks that mount the saw carriage and 4 bolts in the corners of the white casing that hold the casing to the cast top.

You can see by this hinge block compared to the other end in the above picture things are well out.

just comparing the casing to the cast top it looks wrong too.

So using a combination of allen key in the screw head and spanner on the nuts I slackened off all the cast top fixings - except for the one hinge block that already looked nice and centrally mounted. I also left the saw bevel locking screw done up (the bristol lever thing above the depth adjuster handwheel) so the mechanism remained tied to the outer case.

Then it was just a matter of levering the movable end with a screwdriver until the blade was parallel with the table edge. I did check and the table edge is 100% true to the table slots.

Stuck a bit of tape near one tooth and measured the same tooth when front and back of the saw. After a few shoves on the screwdriver it is pretty near perfect. Tightened all the screws up again and re checked and still OK.

Case isn't 100% parallel to the table edge but is very close now... not that it matters really.