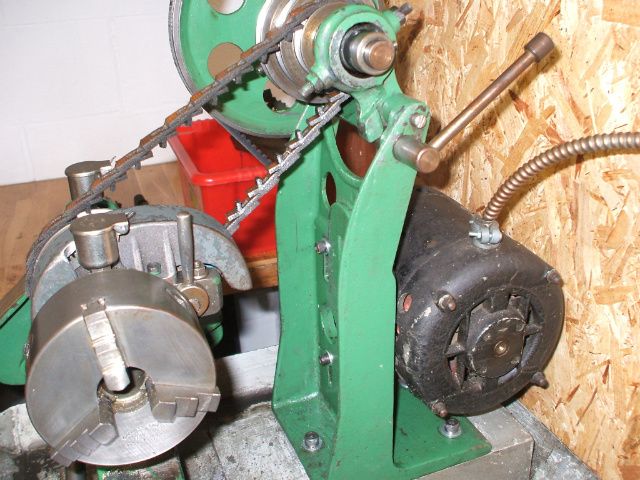

Ok, here's a photo of my latest acquisition. On reflection it may be an ML3, I'm not sure what the difference is.

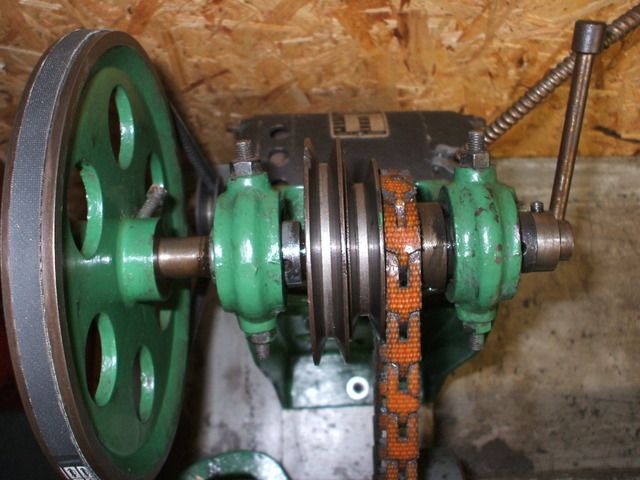

Sorry about the naff photos, my Nikon is in storage at the mo. my main question is about the stand. It's not a standard stand for an ML4, as far as I can tell. Here are the parts:

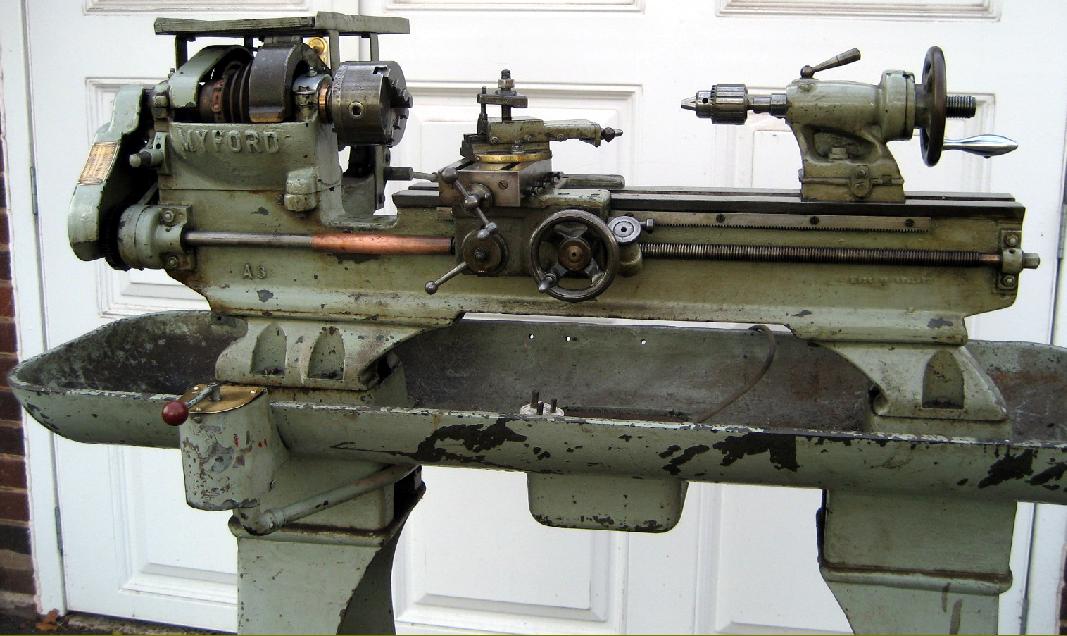

When assembled it looks like this (borrowed from lathes.co.uk, the lathe is a precision 4"):

Curiously, the lathe was mounted to something resembling (but is not) a larger lathe bed, which in turn sits on the chip tray. The "lathe bed" and stand appear to be matched. Here is the "lathe bed". There are no mounting holes on top of it except for four tapped holes that take the ML4:

I'm not sure whether to persevere with this stand or build something a bit smaller.