HI Steve,

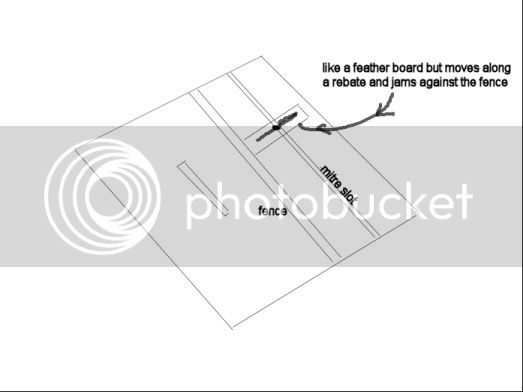

Yes, it's for the 10" SIP CI saw. I spent some more time with it yesterday, sorting out the tops and calibrating the mitre gauge and tape measure for the fence. I have now got the measure within .5 of a mm so it's now quite accurate, although I still hate the fence - maybe I'm doing something wrong, but it seems a bad design. The fence rides along the top of the rail at the front, with just a small plastic thingy holding against the rear rail, therefore there is about 20-30mm of deflection possible unless you move the fence from the middle rather than the handle, even when tightened down I've notice it's quite easy to deflect the fence by about 5mm. I would have thought a fence would be better to run a long a rod shaped rail so that it cannot deflect - am I doing something wrong here?