The slab is down!

Not without a bit of a fight, but it's solid and (mostly) flat which is the important bit.

I calculated that I would need 2.6 cubic metres of concrete, it was a slightly complicated calculation because I was putting the old garage sections into the base to save money, but I was very surprised to unload the full 2.6 metres and still apparently be a long way short of filling the base! Myself and my dad were on wheelbarrow duty while my father in law was doing his best to spread the material out, so we didn't get a chance to start tamping the slab straight away. Well I needed to finish the slab so the guy just kept pouring us more concrete and we kept pouring it in until it looked filled, I ended up using 3.2 cubic metres, which is a hell of a miscalculation!

It turns out, when you only have 3 people on the job and one of them with a bad back and you don't tamp the concrete as you go, it's very easy to end up with what looks like a flat slab of concrete when it is in fact quite a bulging pile of material.

My calculations were pretty spot on and we had to shovel probably the full extra 0.6 cubic metres back out, I now have a step base in front of my shed, a 300kg hot water tank shaped lump of concrete, and an entirely unplanned 2m x 1m slab to one side of the workshop.

It's annoying because it was a huge waste of effort barrowing the material in and then shovelling it back out, not to mention the extra cost, it could all have been avoided if I'd had one more person on site to help out, ah well.

I hired a bull float to try and get a decent finish to the surface, wow those things are good. I floated it while it was still very wet (and there was still daylight left) and got a pretty decent result on the first pass:

I made another pass when it had set a little, trying to improve the finish further, unfortunately this required floating it by headtorch, as it was now 9pm at night. It probably wasn't the smartest idea I've ever had, it's a toss-up as to whether that pass helped or hindered.

I wanted to do a final pass with a magnesium float once it had gone off further, but due to the autumn weather, it was setting very slowly and I wasn't prepared to go out at 1am to do it, by the morning it had gone off enough that no more floating was possible, it's a pretty decent finish generally with a few scars here and there, but should look fine when painted. It doesn't quite meet my vision of a perfect, polished slab, but it's ok for a first go I reckon.

I set a little shuttering in the middle to accept my floor mounted sockets, I may have forgotten to cover it before the rain came in...

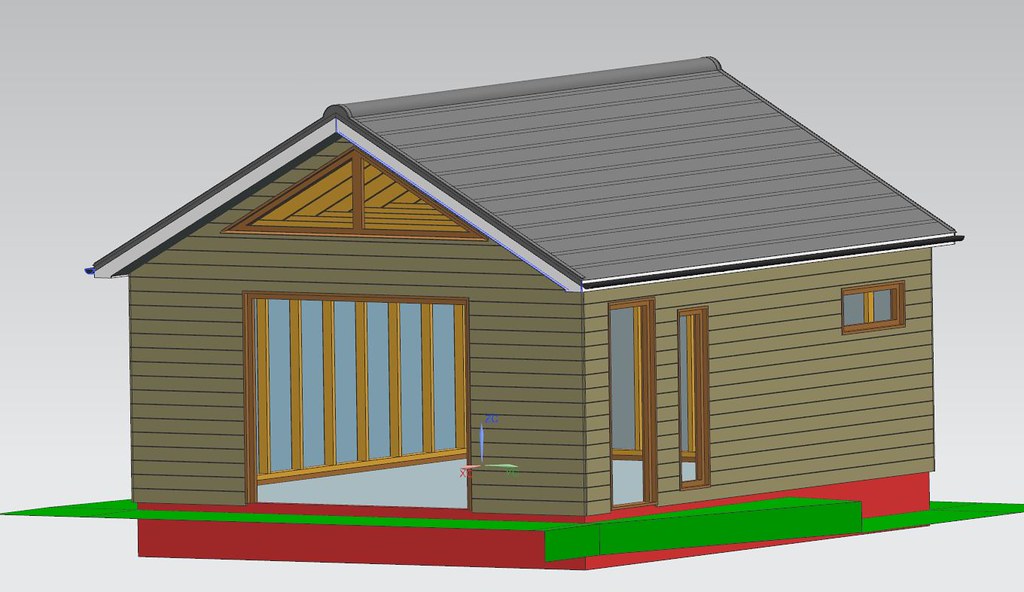

You know what this means though, the next instalment might involve some wood!

Oh, I also got some awesome freebies this week, my dad moved into a new house and the previous occupant left all sorts of gear behind, I bagged a load of new electrical cable, a 110v transformer (in case I ever end up with a 110v tool) and this little puppy:

(it has a compressor too)

It's a little tatty but in perfect working order, I never planned to have air tools in the workshop but it would be rude not to now!