Dandan

Established Member

More progress with the door, the elbow seems to be doing well so I decided to risk cutting a mortice or two, which went pretty well.

These mortices have definitely been the fastest and straightest that I have cut yet, the new wide japanese chisel is great for paring down the inside faces. I managed to put together 3/4 of a door:

The cladding panels were a little snug so I shaved a little more off the ends of some to allow a bit of movement top to bottom, but aisde from that it is all ready bar the last stile.

I've not cut the mortices in the last stile yet but I did fit the hardware for the bifold mechanism. The bottom has a runner, the edge of which will be visible when the door is closed but i'm ok with that:

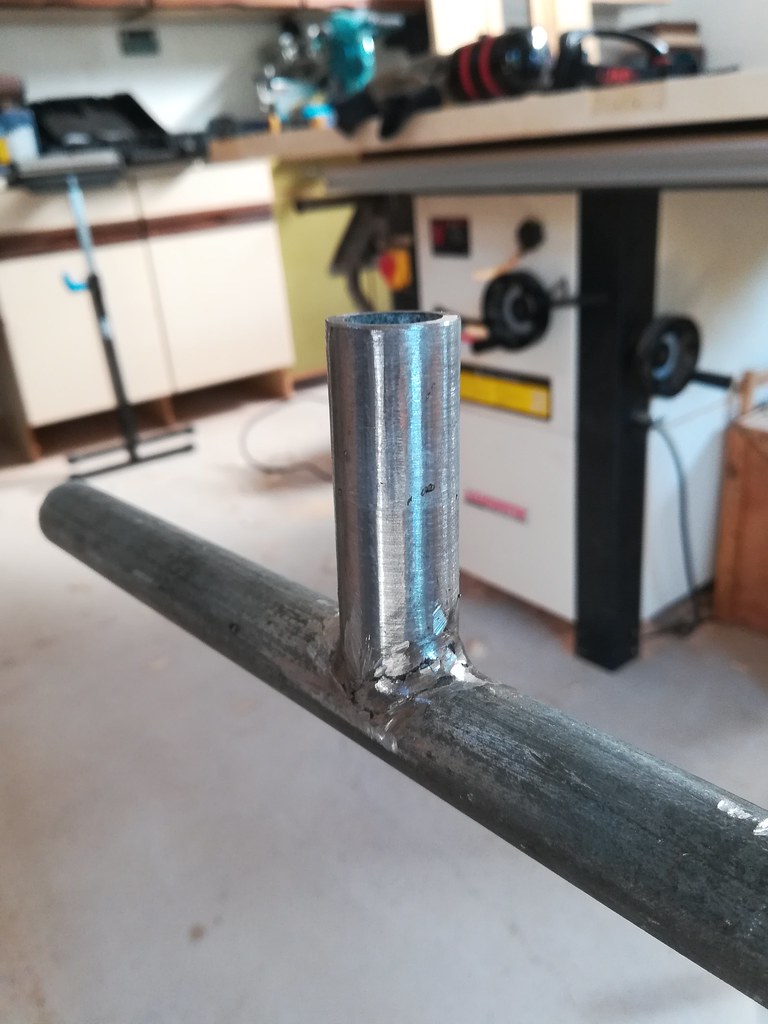

The top required a bit more faff, I actually ground the edge off the bracket so that I could leave some material on the outside face of the door, otherwise i'd have had a gaping hole into my workshop. From the back it looks like this:

But from the front/outside it looks a little neater:

I did a test fit into the rail to check I hadn't got some calculation horribly wrong but it fits well. It did highlight that I need to pack out the top rail a little at one end though, i'm glad I checked as that is easy to do now but would be really hard to do after installing nearly 100kg of doors...

I'll try to get this glued up this week then I can do a test fit!

These mortices have definitely been the fastest and straightest that I have cut yet, the new wide japanese chisel is great for paring down the inside faces. I managed to put together 3/4 of a door:

The cladding panels were a little snug so I shaved a little more off the ends of some to allow a bit of movement top to bottom, but aisde from that it is all ready bar the last stile.

I've not cut the mortices in the last stile yet but I did fit the hardware for the bifold mechanism. The bottom has a runner, the edge of which will be visible when the door is closed but i'm ok with that:

The top required a bit more faff, I actually ground the edge off the bracket so that I could leave some material on the outside face of the door, otherwise i'd have had a gaping hole into my workshop. From the back it looks like this:

But from the front/outside it looks a little neater:

I did a test fit into the rail to check I hadn't got some calculation horribly wrong but it fits well. It did highlight that I need to pack out the top rail a little at one end though, i'm glad I checked as that is easy to do now but would be really hard to do after installing nearly 100kg of doors...

I'll try to get this glued up this week then I can do a test fit!