Dandan

Established Member

Hello all,

I'm a newcomer to woodworking, but I've been a long time lurker, so I know some of the incredible stuff that you lot get up to, i've read all 25,390 pages of Steve Maskery's workshop build so I'm under no illusions that i'll be blowing your minds with my construction skills but thought you might like to see my build anyway. (mostly so I can ask you all lots of questions I should imagine)

I want to get into woodworking as a distraction therapy from messing around with cars, I got a bit tired of laying on cold driveways hammering ineffectually at bits of rusted metal so I wanted a hobby that was a bit more intricate and precise but still hands-on. I thought it might save me some money too until I found the Axminster website...

As a man who can't put down a tool catalogue until every page has been turned, i've already started a collection of hand tools and a few power tools, so I thought I had better build somewhere to put them, and maybe even one day use them!

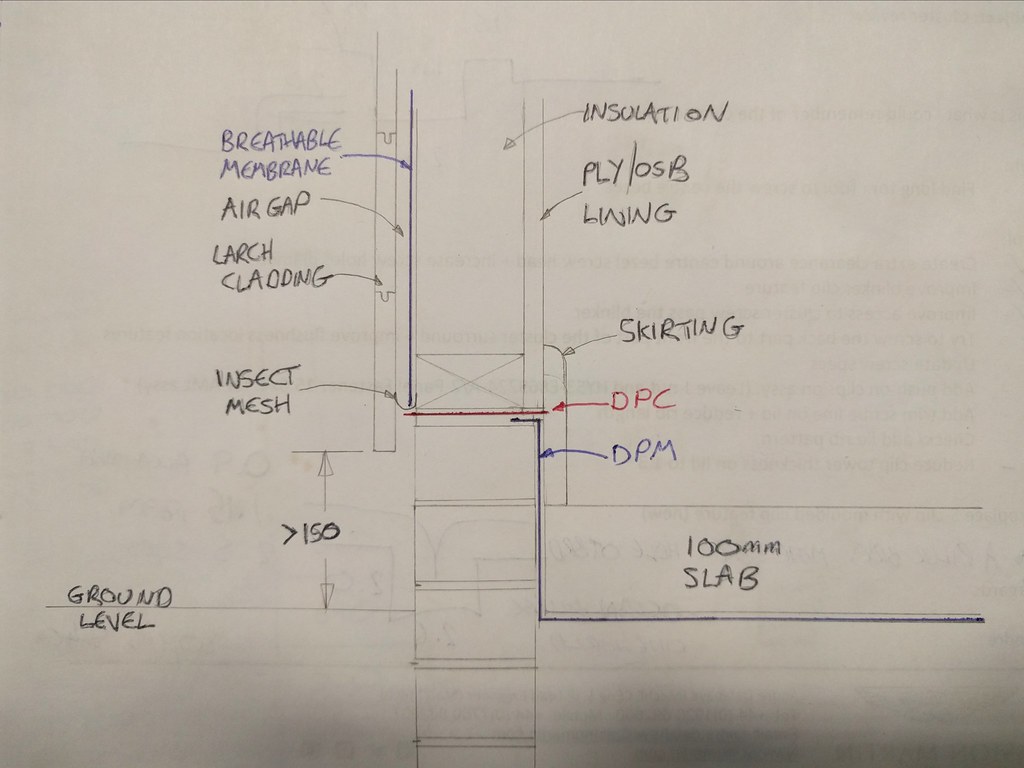

I can't post pictures until I have made 3 posts, so I thought I should start with a question, the workshop will be timber frame on a slightly raise concrete slab with larch cladding, insulation and ply internal cladding, should I get the carcassing timber pressure treated or not?

I'm a newcomer to woodworking, but I've been a long time lurker, so I know some of the incredible stuff that you lot get up to, i've read all 25,390 pages of Steve Maskery's workshop build so I'm under no illusions that i'll be blowing your minds with my construction skills but thought you might like to see my build anyway. (mostly so I can ask you all lots of questions I should imagine)

I want to get into woodworking as a distraction therapy from messing around with cars, I got a bit tired of laying on cold driveways hammering ineffectually at bits of rusted metal so I wanted a hobby that was a bit more intricate and precise but still hands-on. I thought it might save me some money too until I found the Axminster website...

As a man who can't put down a tool catalogue until every page has been turned, i've already started a collection of hand tools and a few power tools, so I thought I had better build somewhere to put them, and maybe even one day use them!

I can't post pictures until I have made 3 posts, so I thought I should start with a question, the workshop will be timber frame on a slightly raise concrete slab with larch cladding, insulation and ply internal cladding, should I get the carcassing timber pressure treated or not?