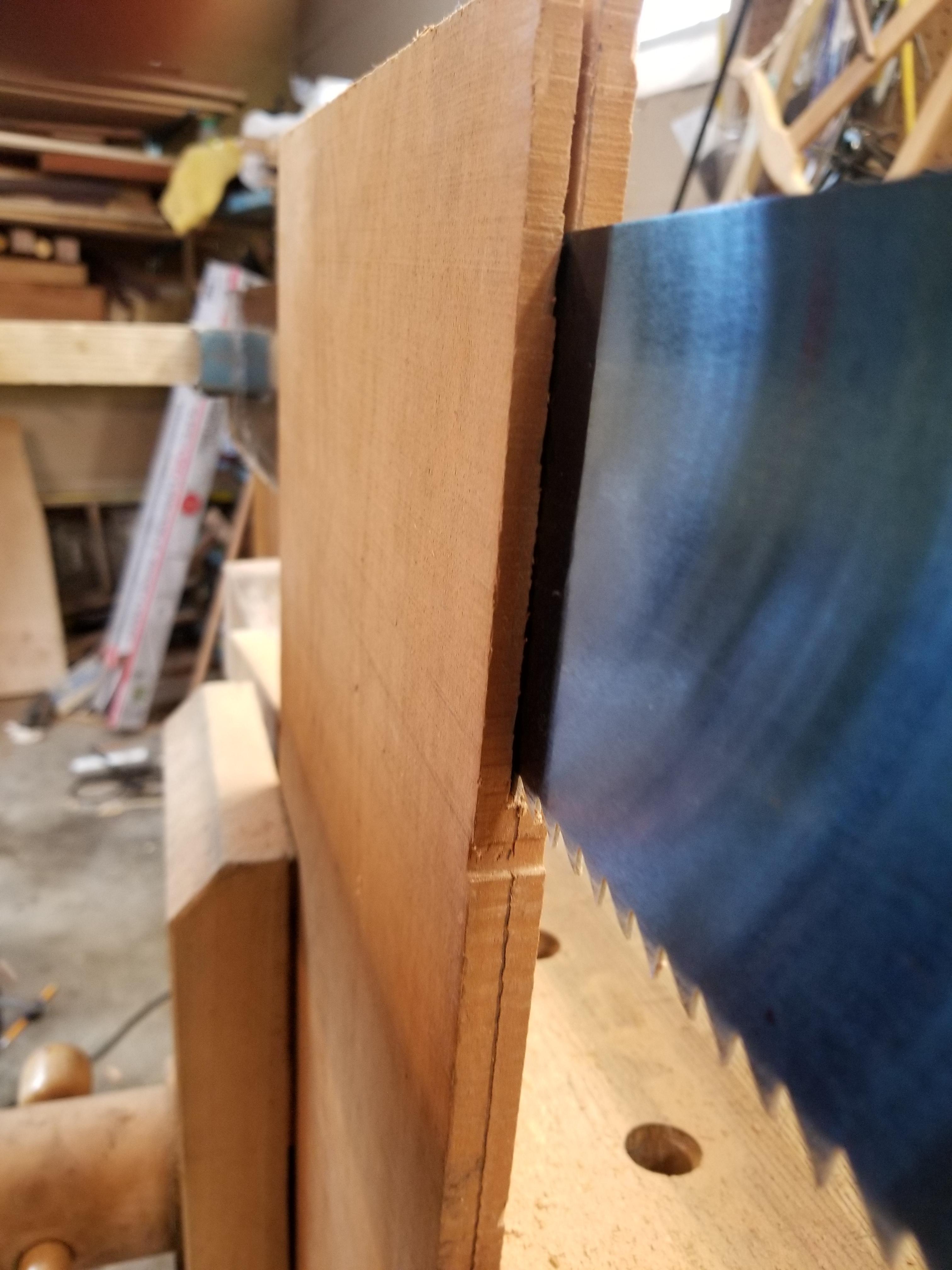

Sawing 8/4 cherry to make the base. A workout. I saw with both arms, and then as I get toward the end of the board, I'll sit if the board allows (cuts right down the middle of the board are ideal - like this one).

I saw with both arms as this takes something like 7-10 minutes (ideal sawing in cherry is about a minute foot, but some allowance for moving the board around). There's absolutely no way I could make a continuous cut with one arm for 7 minutes, but ripping with your non dominant hand is very easy within not-many cuts. Your brain already knows what it wants to see and feel from the other hand and you'll feel plenty powerful when your dominant arm is tiring.

I do have a TS - it's the kind that you can hang on a wall. It's not great for this, and nothing else that I have is accurate. Also, I'll be hand dimensioning this so it's really just a matter of busting it out of this large board and then doing as little as I have to with it to make it suitable to be cut into a base. The top will get a cove with steps at the edge. The top of each case piece will also get a moulding, but I haven't decided yet what it will be. I fancy a roman ogee with a sharp step in the middle, but it pains me to say that I'll have to sand this thing, which ruins the crispness of mouldings. If I don't, they won't take stain and pigment evenly (you read that correctly - the mrs. wants dark, and the only way I found to get dark enough without several steps of dye - which I don't like - is to buy micronized pigments and sprinkle them on while staining - the effect is wonderful).

(at this point, some folks on here are thinking that they'd never waste 7-10 minutes sawing this out, but they would try to figure out how to cut this entire board down and manhandle it around on a table saw or jointer, etc. It will take a little bit longer in total to work this by hand, but not much). The result should be uniform - each stroke of the handsaw is about 1/8th of an inch of cutting - it's pleasant work.

a good result isn't as good as a jointer then tablesaw (like good large good quality tools), but it should be fairly level along its length. Whatever I'm out of square or very slight dips with this will come out easily while planing this to finish, anyway.

The sawdust is appreciable, but not much of it is in the air.

The culprit - an old disston #7. 4 point (3 teeth per inch).

90% of the folks here and on other forums at this point are thinking "big deal". It's not, but the other 10% here who might think that you can't work by hand, and who are already bored with exercising in the first place, this is an awfully good way to go. I don't have a large machine jointer, and I don't fight a small one. The table saw doesn't have to come off of the wall and if you do manage to work on something not time critical, you can split the making and the dimensioning so that dimensioning is exercise and you can come to the shop fresh to do your normal woodworking.

(No dust collection plumbing, either).