RogerS

Established Member

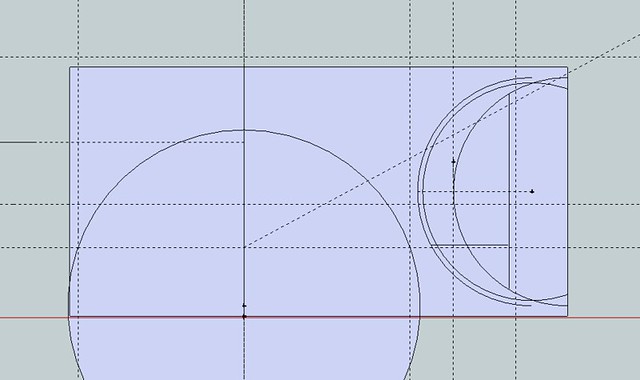

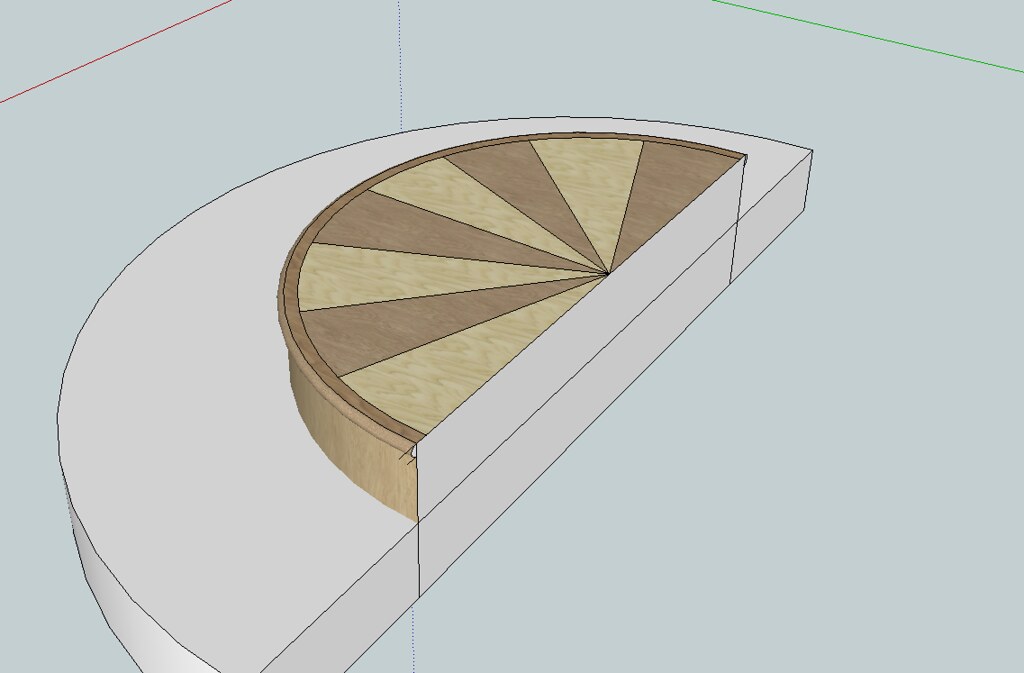

I'm making up this pair of steps to manage the transition in level between two floor levels thus.

Please note...that ghastly colour of the floorboards is not like that in real life !

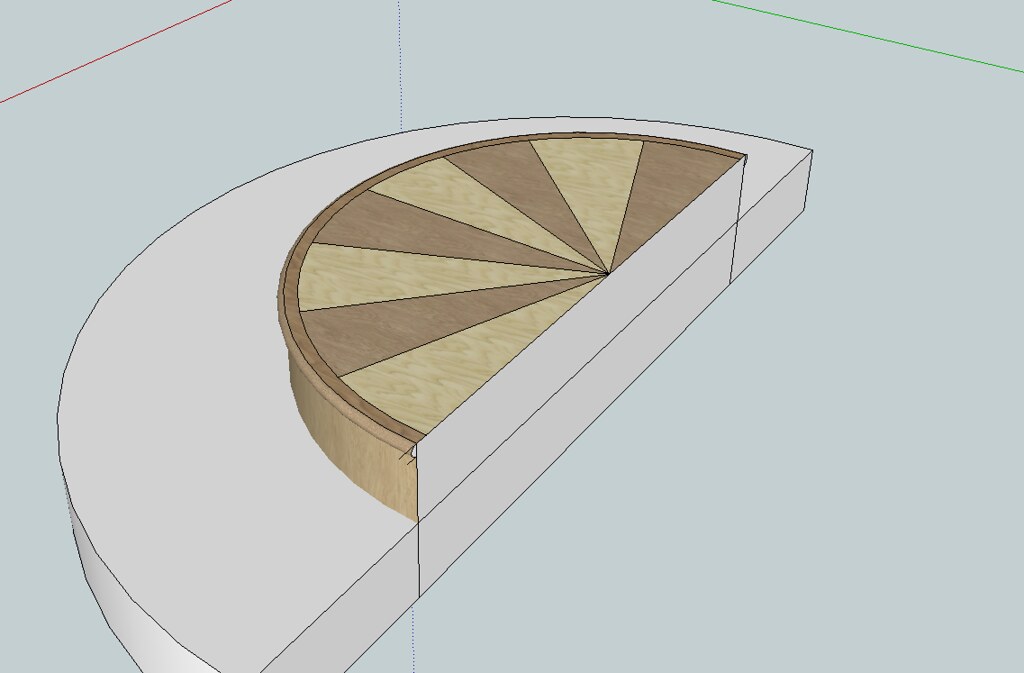

This was my original design but veto'd by CD (Chief Designer)

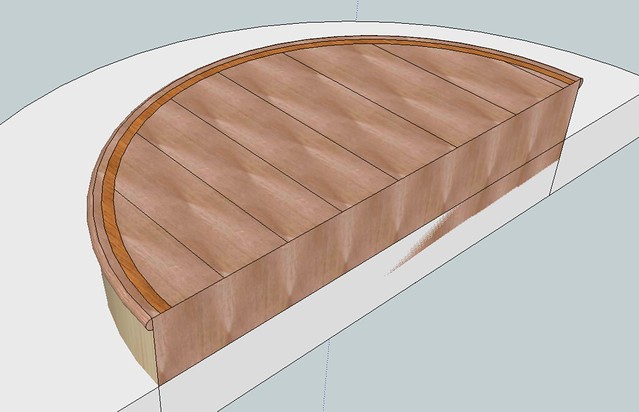

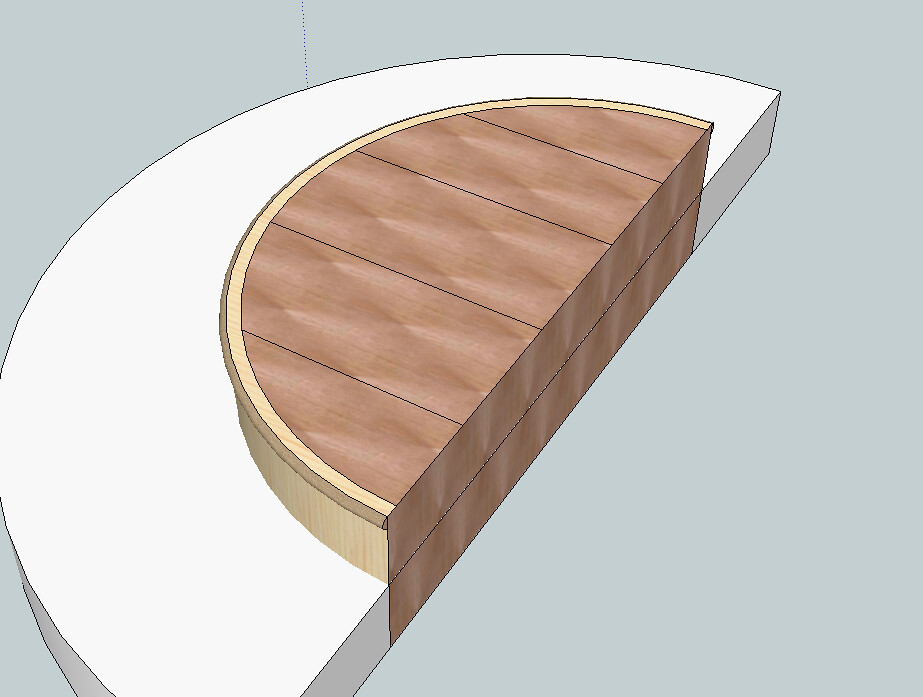

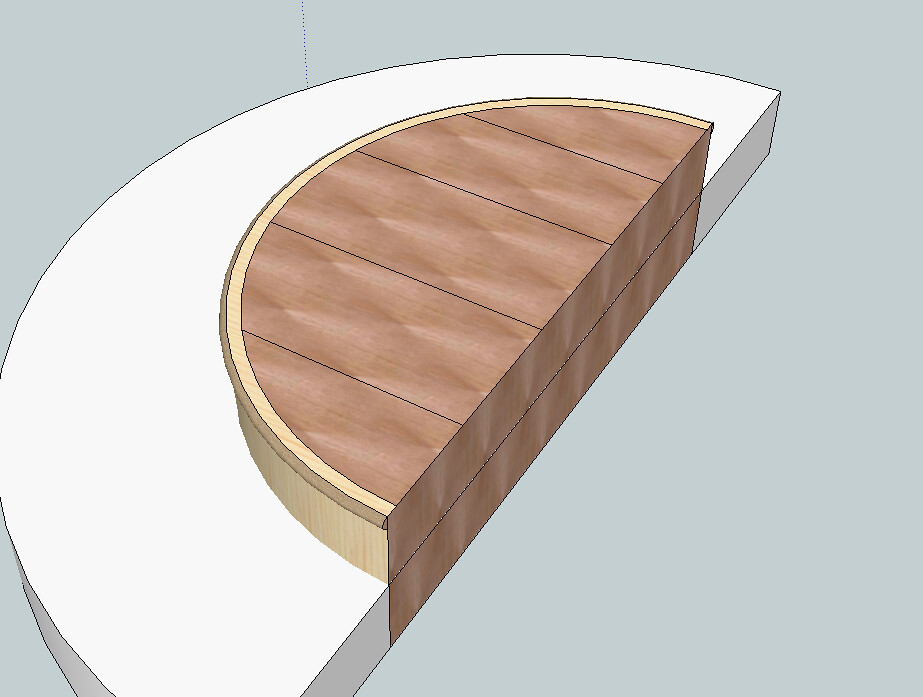

and now the idea is to continue the new floorboards on the higher level continuing through and into the top step as here

NB The floorboards won't be all cutoff in a straight line at the RH side....

I like the idea of that transitional semi-circle to indicate or draw attention to the edge of the step. I planned to have a half-round oak bead then applied on the outer face. All repeated on the lower step. Radii of steps being 550mm and 850mm. Pretty sure that beading off-the-peg could be bent round to fit those radii without too much bother.

But I'm coming round to thinking that beading will look too 'skinny' and that I should have a bullnose moulding instead.

But here's the rub. The overhang of the bullnose doesn't want to be that great otherwise fixing it solidly becomes problematic IMO as there will be leverage from bodyweight. But if I make it too small then I'm struggling to see how I'd make it up (segmented obviously but in as large size segments as I can manage to minimise seeing the breaks ...ideally it would be one single piece. I do have a quote for it to be steam bent but it's a bit eye-watering.

I can mould the half -round using either the spindle moulder or a template trim router bit and a suitable template affixed. But then how do I achieve a smooth curve on the inside radius.....unless the front-to-back width of the bullnose is several cm to give me some sort of flat area to fix down.

But if I make that too large then that transitional half-circle mentioned above gets pushed back inwards towards the centre of the step which then upsets the aesthetics IMO.

Hope this lot is making sense !

Please note...that ghastly colour of the floorboards is not like that in real life !

This was my original design but veto'd by CD (Chief Designer)

and now the idea is to continue the new floorboards on the higher level continuing through and into the top step as here

NB The floorboards won't be all cutoff in a straight line at the RH side....

I like the idea of that transitional semi-circle to indicate or draw attention to the edge of the step. I planned to have a half-round oak bead then applied on the outer face. All repeated on the lower step. Radii of steps being 550mm and 850mm. Pretty sure that beading off-the-peg could be bent round to fit those radii without too much bother.

But I'm coming round to thinking that beading will look too 'skinny' and that I should have a bullnose moulding instead.

But here's the rub. The overhang of the bullnose doesn't want to be that great otherwise fixing it solidly becomes problematic IMO as there will be leverage from bodyweight. But if I make it too small then I'm struggling to see how I'd make it up (segmented obviously but in as large size segments as I can manage to minimise seeing the breaks ...ideally it would be one single piece. I do have a quote for it to be steam bent but it's a bit eye-watering.

I can mould the half -round using either the spindle moulder or a template trim router bit and a suitable template affixed. But then how do I achieve a smooth curve on the inside radius.....unless the front-to-back width of the bullnose is several cm to give me some sort of flat area to fix down.

But if I make that too large then that transitional half-circle mentioned above gets pushed back inwards towards the centre of the step which then upsets the aesthetics IMO.

Hope this lot is making sense !