Hello to all,

We have talked a lot about chisels nowadays… Some posts raised a question in me. How many types of chisels do you use, and at which bevel angles?

I use mortising chisels, driven with a wooden mallet, and sharpen them to approximately 32 deg. I use bevel edged and firmer chisels to chop dovetails and the like, and drive them with a wooden mallet, and sharpen them to approximately 28 deg. I use bevel edge chisels for hand paring, drive/push them with my hands and body, and sharpen them to approximately 23 deg. My chisels are a mixed lot, accumulated over the years. Most of them are carbon steel or simple tool steel. I hand sharpen all of my chisels and plane blades with a simple flat bevel.

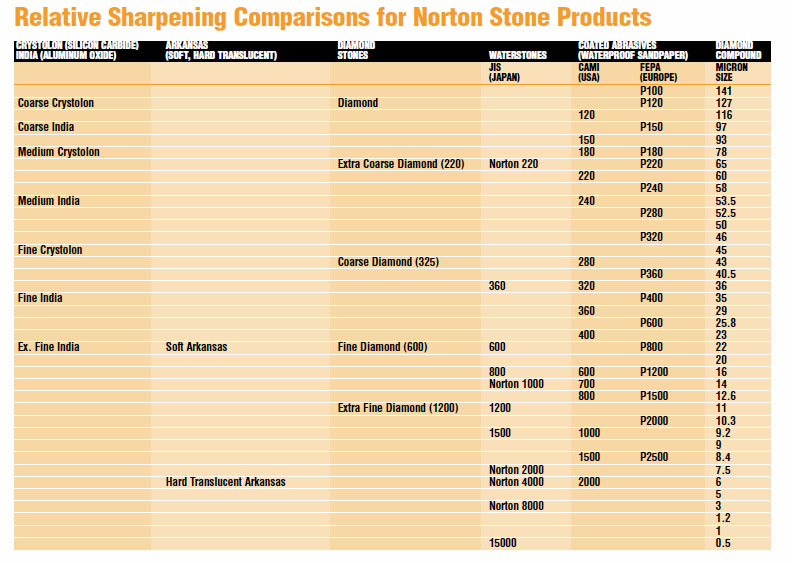

And a further question: some of you mentioned sharpening on “8000 grit”. 8000 grit on what scale? The European standard for bonded abrasives goes to F2000, the particle size of which is 1,2 micrometer +/-0,3 and that is extremely fine.

Have a nice day,

János

We have talked a lot about chisels nowadays… Some posts raised a question in me. How many types of chisels do you use, and at which bevel angles?

I use mortising chisels, driven with a wooden mallet, and sharpen them to approximately 32 deg. I use bevel edged and firmer chisels to chop dovetails and the like, and drive them with a wooden mallet, and sharpen them to approximately 28 deg. I use bevel edge chisels for hand paring, drive/push them with my hands and body, and sharpen them to approximately 23 deg. My chisels are a mixed lot, accumulated over the years. Most of them are carbon steel or simple tool steel. I hand sharpen all of my chisels and plane blades with a simple flat bevel.

And a further question: some of you mentioned sharpening on “8000 grit”. 8000 grit on what scale? The European standard for bonded abrasives goes to F2000, the particle size of which is 1,2 micrometer +/-0,3 and that is extremely fine.

Have a nice day,

János