Rod...there are times when I can be so green with envy...that I could disappear against a bush!

Stunning saws indeed mate...and thanks for the education.

CC...thanks also for your research...I have to get a micrometer on the plate on the Hill....interesting indeed.

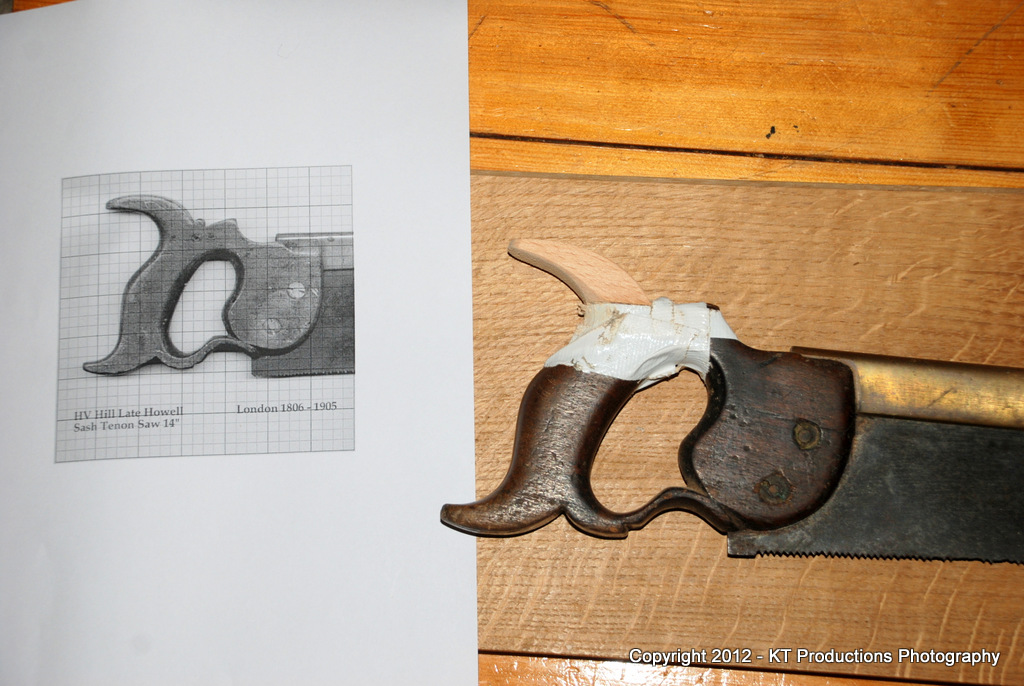

Ok....now...my patience being what it is and my confidence in Pedder's ability being very high...I decided not to wait but fix that horn...as the imbalance was doing my head in!

So...once again a few WIP pictures.

I gave up on the idea of the dovetail. That was silly! Only one shot at it and no going back...I didn't want to hack anything more than I had to out of what was left of the old handle.

So...rule no.1 of repairing using a butt joint...flatten the stock.....

The disc sander is perfect for this as long as the saw was supported horizontally it was easy to sand the stub down....

...this left a nice flat surface to mate the new piece to....

Just a little more to come off the right side as you can see.

Ages ago when I was trading antiques...I saw on Freecycle a post offering a "commode". Thinking this would be an antique one...I asked for it...was successful and picked it up.

To my horror it was one of those beech framed ones with a plastic potty in it....but I didn't have the heart not to take it so I threw away the plastic bit in the nearest bin and chopped up the wood....some nice beech indeed was revealed. This is a leg:

Not quite as old as the saw but nice all the same...and after a quick skim with the old panel plane...perfectly flat.

I then cut a piece of with the grain going in the right direction and tested it against the handle:

A perfect mating....

I always use a lot more stock that I need...I once used a tiny bit too little and now go a bit over the top... :mrgreen:

Titebond Original is the glue that I have always used for these joints...it really works for me and it stronger than the wood under tests that I have done on scrap stock with a hammer. It split the wood.

This applies even to a butt joint..which doesn't have any physical lock like a dovetail.

Careful clamping is a must with these old handles..I don't want to bruise the old wood...

Luckily the bottom curves join to form a nice stable lock....and add a pad with duct tape and cotton wool helps protect the wood further.

Ages ago at a bootfair I picked up what I thought was a set of very old celluloid French curves...

Digging them out of the drawer...I discovered that they matched the shapes on the handle perfectly!!!

This one has a very old No.4 stamped on it....and I wonder if these were a set actually used by a saw maker. A bit of a coincidence if not!

From a Howel template on the Net....I discovered that the other way round matched the top horn...brilliant! I can use it as a guide!

I made a couple of pencil marks to compare to the template so that I got the right one and then ran it through the Burgess with the Tuffsaw blade which made swift work of the excess...

....but tracked the line perfectly..with a little bit over to make adjustments as I finish the stock with rasps and shaves...

Not a bad profile....

The internal curve needs a bit of adjustment to line up in a nice curve with the handle...

....constantly checking against the template. Note at this stage the extreme of the old handle is taped up to protect the finish as much as possible.

That's better!

A number of layers of stain are used to try to lay a foundation that will match the original when polish is added and blended in...

This is locked in with a thin layer of button polish and this helps blend the two parts.

Once dry...000 wire wool is used to blend the finish...and a single layer of button polish is used over the whole handle.

And the other side....

Once this has hardened off...I will take the shine off the whole thing and distress it further to match...but for now...

I'm quite pleased with the outcome and a bit of my wax formula will later tone everything down to original.

Now all I need is to get the blade fixed! :wink:

Jim