devonwoody

Established Member

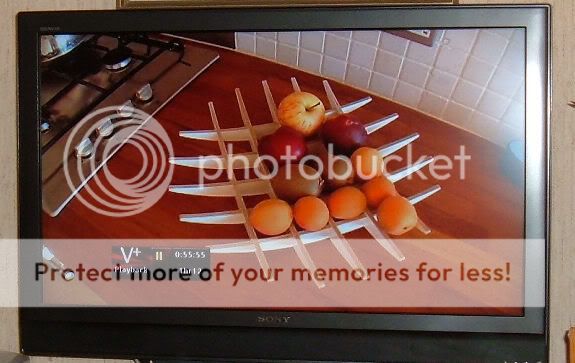

I like it so will use idea to make a fruit stand of my own.

OPJ":jyb9rx6q said:That actually looks dead simple to make... Leaving everything square, cut them all to the same length and cut the notches. After that, do all the shaping and cut them to their individual/paired lengths.

I look forward to seeing what you come up with, though, as you often have good ideas in your box designs.

Dave R":cwds3r3o said:DW, I'll see what I can do. You probably don't want to build from what I drew last night. The curves are compound in my drawing.

Steve Maskery":3h94hdjm said:If I have a criticism it's my concern that that is quite a deep cut to make in one pass, and if you are doing it in two or three then you have the problem of ensuring that the workpiece is in exactly the same place each time. A stop on the fence would sort that out.

Cheers

Steve

Enter your email address to join: