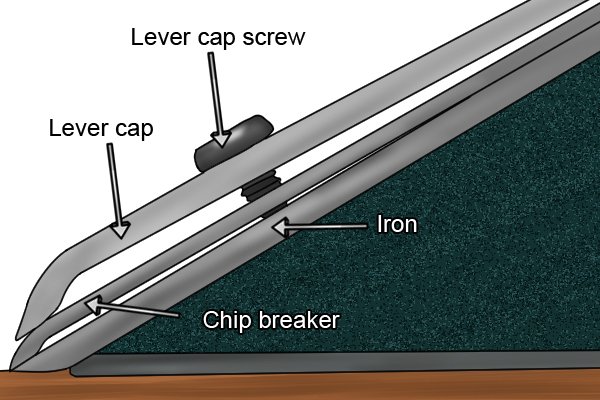

I wonder if it's this issue more than any other that pushes so many woodworking newcomers towards expensive LN/Veritas planes or Bevel Up planes? If you have even the slightest gap between cap iron and blade then planing becomes a horrible chore as you end up with the cap iron way too far back and you still spend most of your time picking out trapped shavings. That's such a dispiriting scenario that it wouldn't be surprising if many aspirant woodworkers just pack it in as a bad job and spend the money on a premium tool that generally works okay straight from the box.

I've been around experienced furniture makers most of my life and the only solution I've ever heard is meticulous flattening to resolve the problem, but IMO that's not really appropriate for most newbies, flattening a crowned plane iron requires quite a delicate touch if you're not to rock the blade from side to side, which then means you could make the problem worse rather than better.

Paul Sellers has a brutal but effective solution for thinner Stanley or Record plane irons, place the iron bevel down on a piece of softwood and bash it once about an inch back from the cutting edge and dead centre with a nylon headed hammer.

I tried this a few times but couldn't get it to work. Turns out I was being too timid. I repeated the exercise with a piece of 6mm MDF on top of the iron and hit it moderately hard with the ball end of a ball pein hammer. This produced an iron with a minute hollow on the cutting face, which made flattening very fast and the cap iron then closed up to give an air tight seal.

I've since repeated the exercise on about four or five thin Bailey style plane irons, returning to a nylon faced hammer but hitting it much harder, it's now worked every time. Make sure there's a piece of flat softwood under the iron, and make sure you're proficient enough with a hammer to get it dead centre.

With that problem sorted cheap Stanley and Record planes are superb tools, toss in DW's closely set cap iron trick and one or two budget priced Record or Stanley tools are all the bench planes that most woodworkers will ever need.

Incidentally, I've sometimes become unstuck with flattening a cap iron because the metal's so soft you can quickly raise a massive wire edge that's tricky to then get rid of, the soft metal means it doesn't just float away like with harder steel and just bends back and forth for ages. I've found that stropping can help, and not to use too aggressive a stone in the first place.