You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Flattening" Chip Breaker

- Thread starter El Barto

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Paddy Roxburgh

Established Member

woodbrains":39tcvdjw said:Hello,

What is a chip breaker?

Mike.

They mean cap iron

woodbrains

Established Member

Paddy Roxburgh":2t72hihw said:woodbrains":2t72hihw said:Hello,

What is a chip breaker?

Mike.

They mean cap iron

Hello,

Indeed! I was being oblique. Perhaps we can write English instead, though.

Incidentally, the cap iron effect is not something new to me. I found out when I was a lad that closely set was helpful for cranky grain. It was just a matter of experimentation, as the setting recommended in books at the time, said close for fine work, but didn't say how close. I just tried closer and closer, until I actually got an effect. I have done it ever since, though I still prefer a fine mouth on my smoother and cottony shaving fine setting on the depth adjuster. Finishing strokes are super fine anyway on my work.

Mike.

woodbrains":2yzfb0k8 said:Indeed! I was being oblique. Perhaps we can write English instead...

'Oblique' is French though? 8)

Paddy Roxburgh

Established Member

NazNomad":237xkctv said:Mmmmnope, I meant chip breaker.

''Cap iron'' was used when Britain 'was' Great, but since the brexit vote we're going all 'murican now.

What, all cuts to be made on unguarded table saw with $5000 dollars worth of Lie Nielsen planes hanging on the wall behind us?

£13.99 (£2.80 / count)

VEVOX® FFP1 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.28 (£3.86 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

"...though I still prefer a fine mouth on my smoother and cottony shaving fine setting on the depth adjuster. Finishing strokes are super fine anyway on my work."

Yep. There's no need to hurry at this stage of the game, especially on projects that have been in process (not yours) for months on end, though we're likely about to be told how 'slow' and 'inefficient' this way of working is.

Yep. There's no need to hurry at this stage of the game, especially on projects that have been in process (not yours) for months on end, though we're likely about to be told how 'slow' and 'inefficient' this way of working is.

CStanford":3sm0kzu6 said:"...though I still prefer a fine mouth on my smoother and cottony shaving fine setting on the depth adjuster. Finishing strokes are super fine anyway on my work."

Yep. There's no need to hurry at this stage of the game, especially on projects that have been in process (not yours) for months on end, though we're likely about to be told how 'slow' and 'inefficient' this way of working is.

Put down the wine, Charlie. The cap iron doesn't do anything for a shaving a thousandth thick, and never has been claimed to.

Then again, neither does a fine mouth - but a fine mouth does prevent a mental error of letting a plane catch on the end of a workpiece at the beginning of a stroke.

El Barto

👍

Out of interest, when buying Bailey planers on eBay etc is there any way of telling if the item truly is one of the older models? I got a No. 5 planer off there a while back and it has moulded plastic handles... they reek of poor quality.

D_W":1sejtlsk said:CStanford":1sejtlsk said:"...though I still prefer a fine mouth on my smoother and cottony shaving fine setting on the depth adjuster. Finishing strokes are super fine anyway on my work."

Yep. There's no need to hurry at this stage of the game, especially on projects that have been in process (not yours) for months on end, though we're likely about to be told how 'slow' and 'inefficient' this way of working is.

Put down the wine, Charlie. The cap iron doesn't do anything for a shaving a thousandth thick, and never has been claimed to.

Then again, neither does a fine mouth - but a fine mouth does prevent a mental error of letting a plane catch on the end of a workpiece at the beginning of a stroke.

Put it down? Never! Wouldn't be efficient...

I'm trying to figure out a way to get the cap iron effect on a corkscrew.

El Barto":y6wv9ttw said:Out of interest, when buying Bailey planers on eBay etc is there any way of telling if the item truly is one of the older models? I got a No. 5 planer off there a while back and it has moulded plastic handles... they reek of poor quality.

http://www.hyperkitten.com/tools/stanley_bench_plane/

D_W":3n4enh4b said:CStanford":3n4enh4b said:"...though I still prefer a fine mouth on my smoother and cottony shaving fine setting on the depth adjuster. Finishing strokes are super fine anyway on my work."

Yep. There's no need to hurry at this stage of the game, especially on projects that have been in process (not yours) for months on end, though we're likely about to be told how 'slow' and 'inefficient' this way of working is.

Put down the wine, Charlie. The cap iron doesn't do anything for a shaving a thousandth thick, and never has been claimed to.

Then again, neither does a fine mouth - but a fine mouth does prevent a mental error of letting a plane catch on the end of a workpiece at the beginning of a stroke.

Dave, I got this little bit of all hand work done today before Happy Hour:

All from rough stock that had not been touched until today (granted, it's poplar), twenty mortises, haunched if applicable, twelve tenons (is that right?,,, damn wine!), legs tapered on the two inside faces, all glued up. This is for our kitchen. The back rail (not pictured) is also four squared and the tenons are laid out but not cut. The top rail and front apron (also not pictured) are also four squared but no joinery has been laid out on them yet. Oh yes, I also laid out the half template for the front apron design on Bristol board.

http://s804.photobucket.com/user/charli ... /Huntboard

Cheers!

I'd like to think so. I thought it was a rather productive day, all things considered and all before 3:00 p.m.

El Barto":80ohkbhp said:Out of interest, when buying Bailey planers on eBay etc is there any way of telling if the item truly is one of the older models? I got a No. 5 planer off there a while back and it has moulded plastic handles... they reek of poor quality.

Type 20 is probably the first type that's considered a dud (in the american made planes), but there can be duds of any year.

My advice would be to find a plane that looks clean and that has an iron with points at the top (not rounded corners), and where the frog goes all the way to the casting and leaves no gap. Points suggest something a little earlier and a bit more consistency with hardness.

I have had a lot of stanley 4 planes, but have one right now. It's a type 20. The iron was relatively soft, but I made an iron in the past and stuffed it in instead - you can always find something vintage wherever you are if you get stuck with a newer soft iron. The rest of the plane is wonderful - it adjusts smoothly and easily and the frog extends all the way to the casting.

At any rate, what I'm getting at is that the plastic handles are offputting from a visual standpoint, but I never minded them that much if they didn't have a seam. I have had bad experiences with planes that had them for reasons other than the handle, though.

Wood handles and irons like I mentioned and you should be fine. If you find you're not, sell what you got on ebay and try again.

CStanford":1f7t3n29 said:I'd like to think so. I thought it was a rather productive day, all things considered.

Planing poplar doesn't prove much in the context of getting a one plane does all kind of thing (custard's demonstration of flattening a ribboned bubinga slab did, though), but I must admit to being a little jealous that so far today, I haven't spent any time in the shop and definitely won't be able to until at least Saturday.

I have no wine at home, either - except fruity stuff that my wife likes, so I guess there will be no relief tonight. I prefer wines a little closer to my personality profile.

Well, Dave, I wasn't out to prove anything with regard to planing.

rafezetter

Troll Hunter

Pete Maddex":2aovyakm said:Its something I struggle with, I find the best way is to lap the cap iron on a diamond plate resting on the blade, the thickness gives you a clearance angle and by using the blade as a base it comes out parallel to the cutting edge.

If you don't get a good fit shavings will clog the blade very fast.

Pete

This is a brilliant idea, I have a few cap irons in my woodies that are not quite as snug as I'd like and several attempts hasn't really improved them much, I can use my small credit card diamond sharpener to finish off after checking the blades first.

bugbear

Established Member

NazNomad":148pvskb said:

Heh. That cap-iron is a little too close, even by D_W standards - it's covering the blade completely. :lol:

BugBear

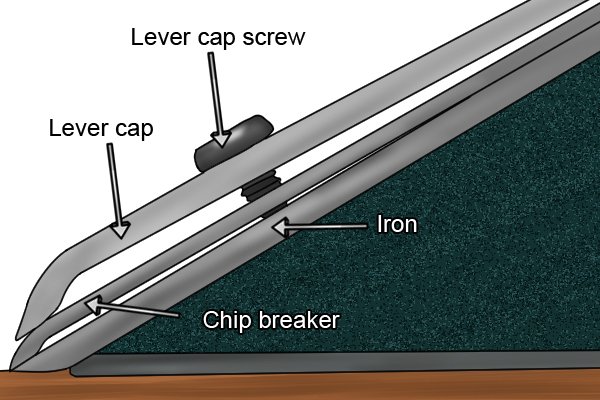

El Barto":qqme9s24 said:Doing a bit of sharpening today and on a couple of second hand planes the chip breakers don't sit perfectly flush with the iron.

A few goes on the stone gets an improvement but still got gaps on both sides. Is it just a case of working the breaker on the stone until it's square and flat?

I'm sure somebody must have already mentioned it but you need to figure out if the breaker is high in the middle or the plane iron has a bump or it's a little of both. Hopefully, it'll just be the breaker since the steel is soft and easy to remove. You can easily put selective pressure on the breaker where it's high while rubbing it on an oilstone or sandpaper on a flat surface.

This video may be of some help. Maguire has a no-nonsense, direct approach to getting tools ready for work and not making a career out of hand plane tuning. As with any woodworking instruction there will always be those who have quibbles. Judge it for yourself.

If your cap iron is just a wreck, sometimes it's easier to replace it on the vintage market or aftermarket new.

http://www.theenglishwoodworker.com/pre ... ker-video/

Similar threads

- Replies

- 61

- Views

- 7K

- Replies

- 7

- Views

- 2K