DangerousDave

Established Member

Hello all,

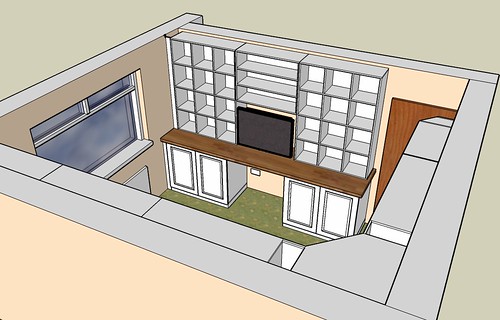

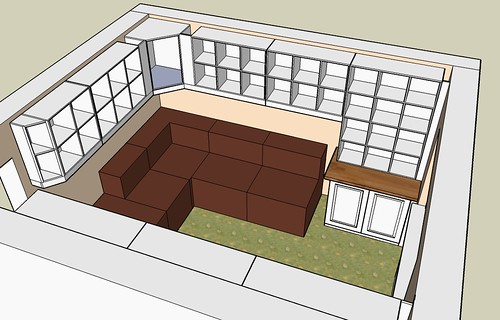

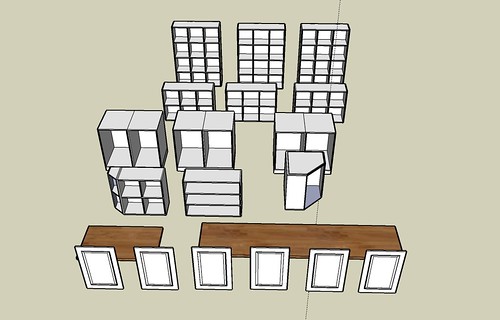

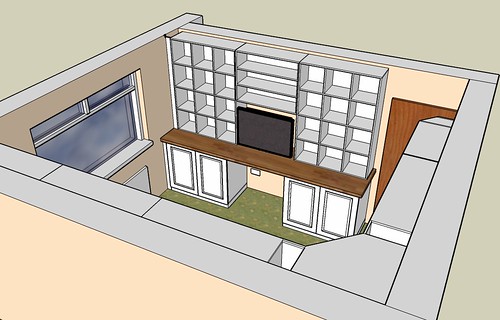

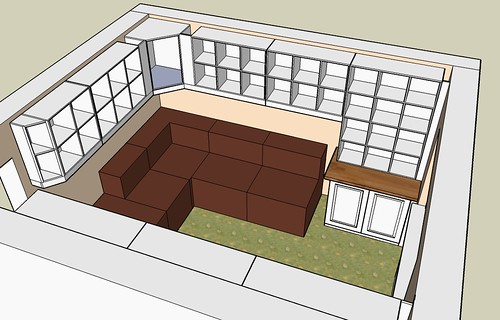

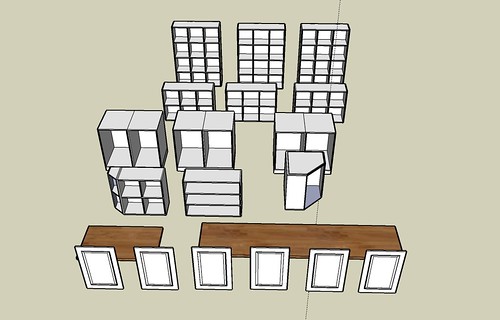

Inspired by Dan's latest creations in painted MRMDF, here's my SU design for fitted cabinets for a family room

The original plan was to use 15mm MRMDF but now I'm having second thoughts. I compiled a cutting list using the excellent WoodWorks optimization software (http://woodworks.at) and the MDF will be about £350. I'm now thinking about using solid wood (jointing up panels from narrow boards, faced ply for backs) perhaps Ash or Beech with a natural finish instead of painted. Its gonna take a bit of mental gymnastics to work out quantities from my original cutting list, not sure how much more expensive this will be but at least I can buy sawn boards as I'm able to plane and thickness. This one's for my own house and I'm really coming round to the idea of a timber finish as opposed to painted MDF. Also jointing up panels would make a nice change from cutting endless amounts of man made boards :roll: I would need to rejig the design a bit to account for the carcass joints (originally allowed for simple butt joints in the carcasses with the MDF). What would you guys do?

Inspired by Dan's latest creations in painted MRMDF, here's my SU design for fitted cabinets for a family room

The original plan was to use 15mm MRMDF but now I'm having second thoughts. I compiled a cutting list using the excellent WoodWorks optimization software (http://woodworks.at) and the MDF will be about £350. I'm now thinking about using solid wood (jointing up panels from narrow boards, faced ply for backs) perhaps Ash or Beech with a natural finish instead of painted. Its gonna take a bit of mental gymnastics to work out quantities from my original cutting list, not sure how much more expensive this will be but at least I can buy sawn boards as I'm able to plane and thickness. This one's for my own house and I'm really coming round to the idea of a timber finish as opposed to painted MDF. Also jointing up panels would make a nice change from cutting endless amounts of man made boards :roll: I would need to rejig the design a bit to account for the carcass joints (originally allowed for simple butt joints in the carcasses with the MDF). What would you guys do?