You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Files and Filing

- Thread starter AES

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AES

Established Member

Agreed, there ARE "proper" lathe files, and they do (usually) have 2 safe edges. In wasn't aware that ArcEurotrade have them (good company IME BTW, usual disclaimers) and I thought lathe files were pretty rare these days. I have just a couple I inherited from my dad.

Within reason, IMO you can use just about any file on the lathe (NOT a Dreadnought for example!) and I believe that jewellers & watchmakers often use Swiss and needle files on the lathe for final dimensioning of small pivots and the like. But as said, using a sensible lathe speed, a suitable file for the job and its material (basically you're fine finishing), you can use just about any file that suits. Or even emery of wet n dry wrapped round a file. And if you must have a 2nd safe edge on a file you can of course grind it away for all (or part) of its length.

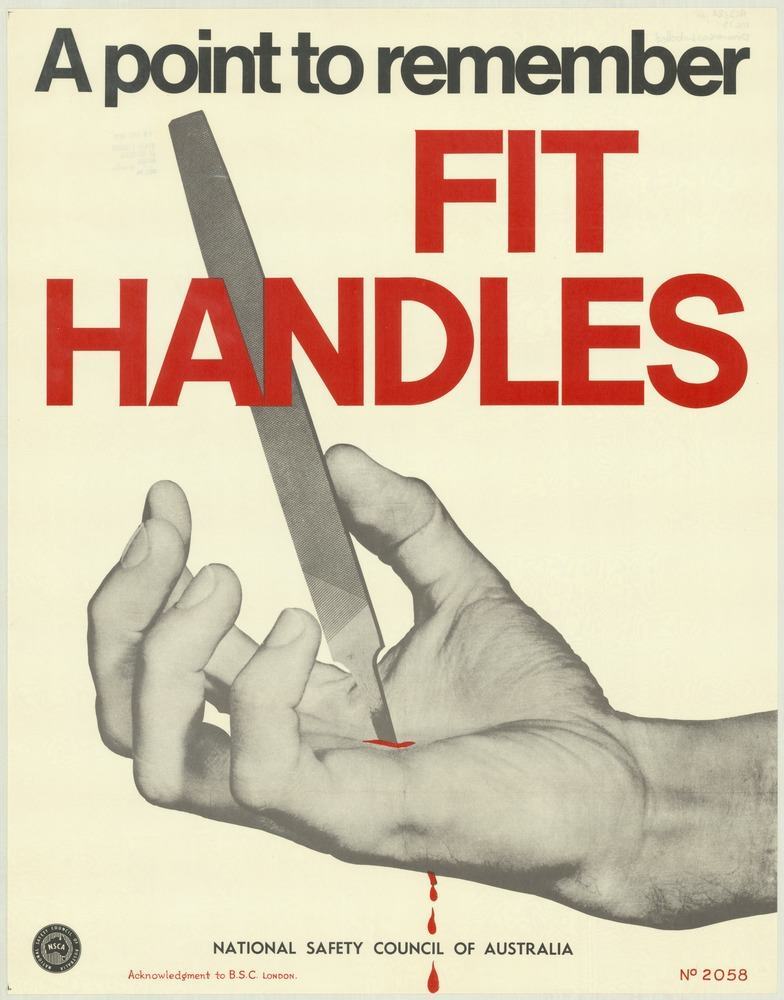

BUT, PLEEZ, whatever file you use, DO be careful and ALWAYS use a handle and NEVER just a bare tang - catches can occur sometimes and if they do they WILL happen at a speed which will definitely NOT allow you to react in time. Same applies to using a file in the pillar drill.

"Lecture rant" over.

P.S. @TFrench. Thanks for the "proper engineer" cachet above, but looking at your current thread "you ain't no slouch yerself mate"!

Within reason, IMO you can use just about any file on the lathe (NOT a Dreadnought for example!) and I believe that jewellers & watchmakers often use Swiss and needle files on the lathe for final dimensioning of small pivots and the like. But as said, using a sensible lathe speed, a suitable file for the job and its material (basically you're fine finishing), you can use just about any file that suits. Or even emery of wet n dry wrapped round a file. And if you must have a 2nd safe edge on a file you can of course grind it away for all (or part) of its length.

BUT, PLEEZ, whatever file you use, DO be careful and ALWAYS use a handle and NEVER just a bare tang - catches can occur sometimes and if they do they WILL happen at a speed which will definitely NOT allow you to react in time. Same applies to using a file in the pillar drill.

"Lecture rant" over.

P.S. @TFrench. Thanks for the "proper engineer" cachet above, but looking at your current thread "you ain't no slouch yerself mate"!

I'm just a YouTube educated bodger! I got this lathe file a couple of weeks ago, it's a beauty. NOS and with an integral handle.

Link to the arc lathe files

https://www.arceurotrade.co.uk/Cata...ra-Files/Special-Files/Long-Angle-Lathe-Files

Sent from my SM-G973F using Tapatalk

Link to the arc lathe files

https://www.arceurotrade.co.uk/Cata...ra-Files/Special-Files/Long-Angle-Lathe-Files

Sent from my SM-G973F using Tapatalk

AES

Established Member

Yup, that's very much what the 2 from my dad look like. Really didn't realise they're still made/available.

Just to "reinforce" the above safety message - this type clearly does not need a handle, but EVERY other type does, including Swiss & needle files (for which little wooden handles are available).

Just to "reinforce" the above safety message - this type clearly does not need a handle, but EVERY other type does, including Swiss & needle files (for which little wooden handles are available).

Trevanion

Greatest Of All Time

Robbo3

Established Member

A visitor to my shed wanted to know how to de-gunge a file so I showed him my file card. This begged the question as to whether fine, medium & coarse file cards were required, to which I didn't know the answer & said I would try to find out.

Although I've had a cursory search I can see no reference to any types or sizes of files that a file card is suitable for.

Hence my asking the question here.

Although I've had a cursory search I can see no reference to any types or sizes of files that a file card is suitable for.

Hence my asking the question here.

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£19.33 (£3.87 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£13.99 (£2.80 / count)

VEVOX® FFP1 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

For when a file card isn't enough (e.g. metal blobs) a piece of copper pipe, flattened at the end, makes for a good deep clean. The file eats away the copper to form a matching set of teeth that [Madonna]get into the grooves[/Madonna] and clean it out pretty well.

AES

Established Member

AFAIK, there are no different grades of file cards.

Agree with a bit of copper wire to clean clogged files (ali is a particular problem) but what also works for me is the (now blunt) end of one of those cheapo snap off blade knives).

Cleaning "a" file that way is quite therapeutic I find, but do NOT wait for half a dozen to need such attention, as "therapeutic" soon becomes "VERY boring"!

Agree with a bit of copper wire to clean clogged files (ali is a particular problem) but what also works for me is the (now blunt) end of one of those cheapo snap off blade knives).

Cleaning "a" file that way is quite therapeutic I find, but do NOT wait for half a dozen to need such attention, as "therapeutic" soon becomes "VERY boring"!

Dalboy

Established Member

After today I will need to clean three files of ali, the needle file will be easy the other two will need a little more attention.

Why are my files multiplying I will soon have more than turning tools :lol: :lol: :lol:

Why are my files multiplying I will soon have more than turning tools :lol: :lol: :lol:

AES

Established Member

@Sammy.se. Thanks, my pleasure Sir (glad to "give something back" here for once, my woodworking "skills" are NOT all that up to much)!

@dalboy: Yup, getting ali out of files is a bit of a barsteward (I DID warn)! If you're doing a lot of ali, especially the softer alloys, it's worth while breaking off "in the middle" of a job to give them a quick brush up. Not only does it give you less of a task at the end of a job but it also increases the cutting efficiency of the file/s.

As to files "multiplying", yup, they tend to do that! OTOH they are useful tools and though I don't own any turning chisels, I guess that piece for piece they're cheaper than turning tools.

@dalboy: Yup, getting ali out of files is a bit of a barsteward (I DID warn)! If you're doing a lot of ali, especially the softer alloys, it's worth while breaking off "in the middle" of a job to give them a quick brush up. Not only does it give you less of a task at the end of a job but it also increases the cutting efficiency of the file/s.

As to files "multiplying", yup, they tend to do that! OTOH they are useful tools and though I don't own any turning chisels, I guess that piece for piece they're cheaper than turning tools.

Dalboy

Established Member

AES":3cxxxuzp said:@dalboy: Yup, getting ali out of files is a bit of a barsteward (I DID warn)! If you're doing a lot of ali, especially the softer alloys, it's worth while breaking off "in the middle" of a job to give them a quick brush up. Not only does it give you less of a task at the end of a job but it also increases the cutting efficiency of the file/s.

As to files "multiplying", yup, they tend to do that! OTOH they are useful tools and though I don't own any turning chisels, I guess that piece for piece they're cheaper than turning tools.

I did give them a brush with the card every so often as I could not find my chalk. And yes turning tools a lot more expensive

AES

Established Member

@dalboy: Yeah, agreed, ali, especially the softer alloys, tend to "melt" (at least get very soft) for a milli-second during the cutting process, so the residue sticks like an army blanket into the teeth. If you're going to do a lot of ali filing I can only suggest you buy at least 1 file specifically for the purpose (they clog too, but less so, due to the chip breaker design). Don't know if they're still available new these days, but I've found the Oberg Cut or Baiter Aluminium file both very good for fast material removal with minimum (but still some!) clogging.

See pix FF11 & FF 12 in Pt 2 of my OP here.

If you can't find either of those (you'll need a good local tool shop - any in Canterbury?) then a Dreadnought is good too - maybe easier to find? The only other thing I can suggest (not teaching granny all about egg sucking - hopefully!) is to "refine" your cutting out skills so you get nice and tight to the line.

Otherwise "Just keep taking the tablets Brian"!

See pix FF11 & FF 12 in Pt 2 of my OP here.

If you can't find either of those (you'll need a good local tool shop - any in Canterbury?) then a Dreadnought is good too - maybe easier to find? The only other thing I can suggest (not teaching granny all about egg sucking - hopefully!) is to "refine" your cutting out skills so you get nice and tight to the line.

Otherwise "Just keep taking the tablets Brian"!

Dalboy

Established Member

Don't file ali much and this was a case of I had to file the way I did because I was making a round hole square just big enough to get the smallest file I have other than the needle files Both square holes now filed and files cleaned and put away for the next job. :wink:

AES" Otherwise "Just keep taking the tablets Brian"