Michael_b

Established Member

Putting the lie to my reply (in regards to no longer engaging with you), you edited the post and still didn't answer the question or back up your claim. I provided photos. Try again.Ah, still can't answer any questions or back up any claims. Good luck with your "superior skill." I'll stop engaging with you and learn from people who actually have something to teach me. I have a great deal to learn, but clearly not from you.

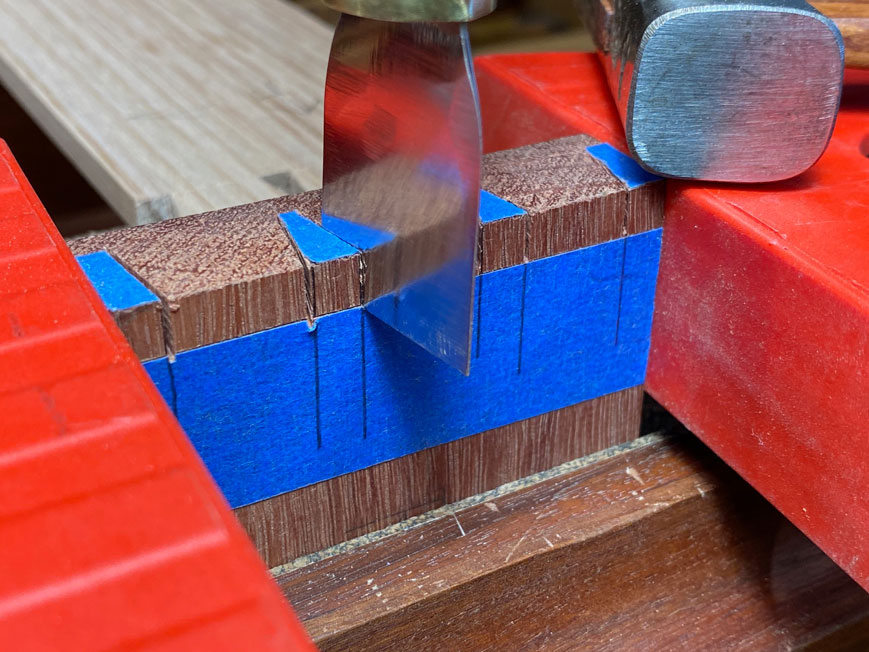

"I'd write it up differently if I repeated the exercise - several little improvements. Best of all was the "beam" hold-down which I've used a lot since, with variations. It can hold down all your drawer sides, or the cabinet 4 sides, at once and you can chisel them all without changing their position until you have to turn them all to do the other side."

Last edited: