wcndave

Established Member

I have had a domino for around a year now, and did a couple of quick bits that i found it great for. however i have now started to make proper use of it, cos let's face it, it's a bit dear to buy one for one small DIY job ;-)

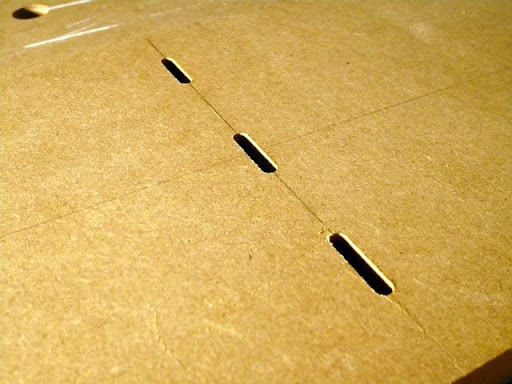

one question I have is how to join end to middle at right angles.

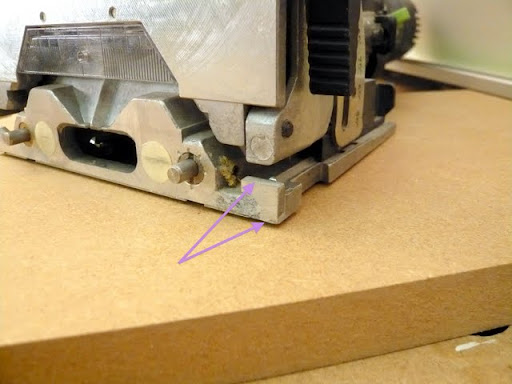

in the past i would do a dado by hand router, or a sliding dovetail by woodrat. however with the plastic guide off, it seems that the distance from middle of mortice to any baton I use to measure against is 10.5mm.

this means if i am working with 12mm stock for example, then middle of stock to edge is 6mm, take that from 10.5, I need so measure away 4.5 from my line, and work to there...

Is a little bit fiddly and I wondered if there was a better way to do it?

Thanks

Dave

one question I have is how to join end to middle at right angles.

in the past i would do a dado by hand router, or a sliding dovetail by woodrat. however with the plastic guide off, it seems that the distance from middle of mortice to any baton I use to measure against is 10.5mm.

this means if i am working with 12mm stock for example, then middle of stock to edge is 6mm, take that from 10.5, I need so measure away 4.5 from my line, and work to there...

Is a little bit fiddly and I wondered if there was a better way to do it?

Thanks

Dave