seaco":37b974y9 said:

Well simply because the router would be in use alot longer hence more chance of injury, it's not rocket science... I'm not saying the router is more or less dangerous than a dado but the longer a machine is switched on the more chance of something going wrong...

I don't entirely agree. Time of cut is not the safety issue, it's potential exposure to cutter which is.

seaco":37b974y9 said:

Earlier posts say a router is quicker and easier to use well try cutting a 11.5mm wide trench 15mm deep in oak in one pass? I would need a hundred cutters to make up all the combinations of width I can do with my dado set...I know I can do multiple passes but that in itself adds more chance for injury

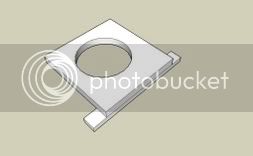

The majority of housings people work are probably to accommodate the likes of shelves and rails, etc in sheet stock (18mm, 15mm and 12mm) and you can comfortably accommodate an 18mm wide x 9mm deep housing in a single pass with a 1/2in router. To adjust the cut it is probably simpler to add a rebate to the end of shelf, thus (BTW also true for dado heads):

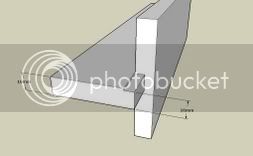

This is a 16 x 9mm housing worked in 19mm stock (because the only cutter available is notionally 16mm) with a rebate in the top edge of the shelf. As the piece is to have a "face-frame" attached it doesn't matter what the end of the housing/shelf looks like - and I'd say that was true for most housed work. Better quality pieces would, in any case, be worked with a stopped housing or a different joint altogether. The jig to cut the housing looks like this:

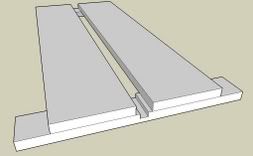

The gap between the boards is 30mm to accommodate a 30mm O/D guide bush frequently supplied with a 1/2in router (the size normally used for kitchen worktop and stair housing jigs, etc), but there's no reason why a smaller guide bush couldn't be used. As the cut is made into the cross rail, this becomes a "register mark" for cutting the housings:

Total jig cost, circa £6 (nil if scrap used) - total cutter cost, circa £25 (for 12mm and 16mm) - total time to make, circa 15 minutes. set-up time is just your marking-out time really...... And because your hands are always above the cutter holding the router probably a heck of a lot safer that the dado head. Noise? Buy a Bosch or Mafell or Festool router and they are considerably quieter than the DW625 I use, but in reality the majority of the noise is made by the cutter on the timber in either case - so wear ear defenders.

There is also another fact to consider - that housings rob strength from chipboard, MFC and MDF and thus aren't suitable for use with those materials.

My experience of using stuff like trenching heads is that they can be a royal time-consuming pain to set to the right width and are only worth considering if you have a lot of identical cuts to make.

So, if not sheet materials what exactly do you use your dado head for?

Scrit