People go to great lengths to source a fine piece of leather and then proceed to slather on an obviously too thick layer of crayon, which by the way are meant for power buffing as the wax vehicle melts at speed when tool is touched to wheel exposing the grit.

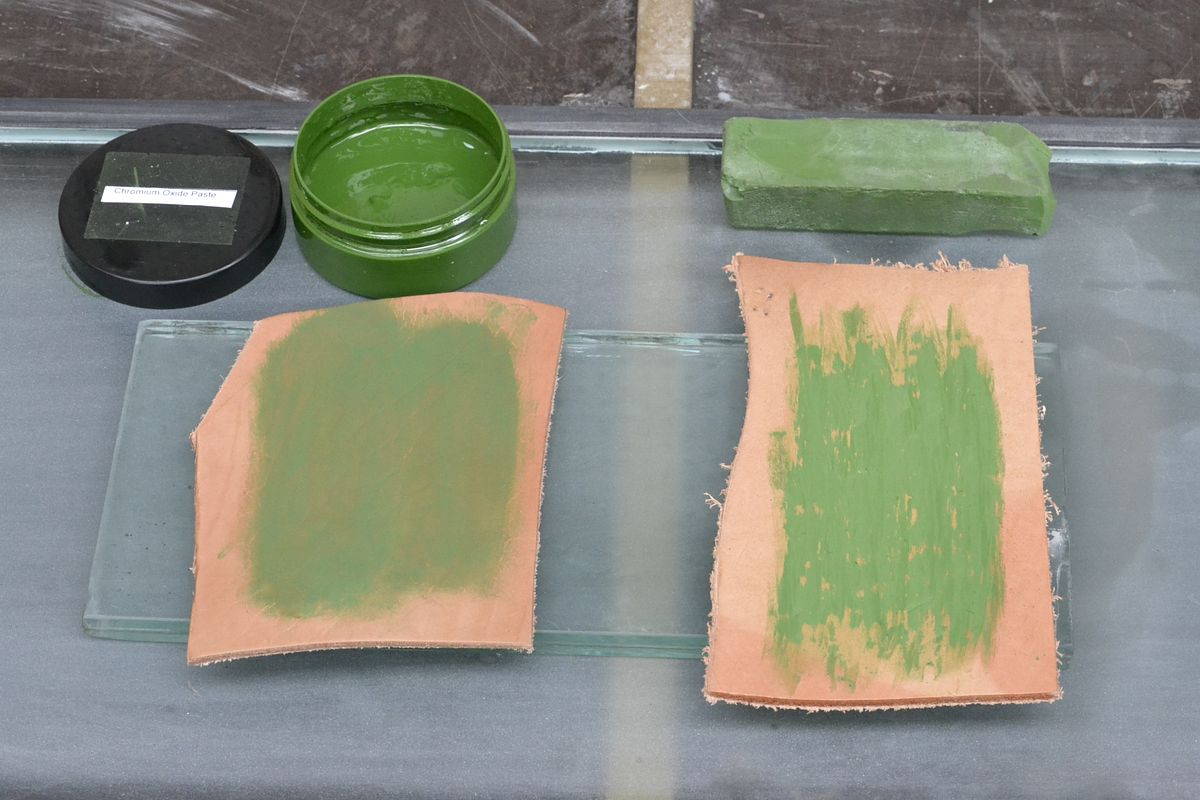

Leather should be treated with a paste compound, or dry compound with a little oil and it should be hard to discern whether it has been treated at all. This represents about the right amount of 'charge' for the strop. If you believe leather, itself, is efficacious it makes no sense to clog it with crayon that was meant for your electric buffer in the first place. If you consider the leather to be nothing more than a substrate to be obscured by a wax compound then any cheap piece will do as the implement being honed is not really contacting the leather in any meaningful way.

Or just use a firm composition rubber and dry powder as your strop, though it's essentially functioning as an ultra-fine stone perhaps a distinction without a difference. Any final medium equivalent to about 1500 to 2000 grit sandpaper or finer needs no 'strop' per se as very light final passes on the slightly worn paper polishes and doesn't produce a noticeable wire.

3M makes a 5000 grit sandpaper and if you think you need something finer (if even this fine) then it's likely more a matter of psychology than anything having to do with producing edges for woodworking. As previously mentioned those so inclined can move into the realm of .05 micron abrasives used on optical and other laboratory devices but it gets absurd well before this point IMO. Earth pigments are used to polish gold because they temporarily enhance its natural color. In a woodshop they would be a source of staining of the fingers which might transfer to a project. There is no advantage to using jeweler's rouge, artist's pigments, etc. vs. other products for honing woodworking tools.

https://www.amazon.com/Trizact-5000-Gri ... B00LIXEWXO

Leather should be treated with a paste compound, or dry compound with a little oil and it should be hard to discern whether it has been treated at all. This represents about the right amount of 'charge' for the strop. If you believe leather, itself, is efficacious it makes no sense to clog it with crayon that was meant for your electric buffer in the first place. If you consider the leather to be nothing more than a substrate to be obscured by a wax compound then any cheap piece will do as the implement being honed is not really contacting the leather in any meaningful way.

Or just use a firm composition rubber and dry powder as your strop, though it's essentially functioning as an ultra-fine stone perhaps a distinction without a difference. Any final medium equivalent to about 1500 to 2000 grit sandpaper or finer needs no 'strop' per se as very light final passes on the slightly worn paper polishes and doesn't produce a noticeable wire.

3M makes a 5000 grit sandpaper and if you think you need something finer (if even this fine) then it's likely more a matter of psychology than anything having to do with producing edges for woodworking. As previously mentioned those so inclined can move into the realm of .05 micron abrasives used on optical and other laboratory devices but it gets absurd well before this point IMO. Earth pigments are used to polish gold because they temporarily enhance its natural color. In a woodshop they would be a source of staining of the fingers which might transfer to a project. There is no advantage to using jeweler's rouge, artist's pigments, etc. vs. other products for honing woodworking tools.

https://www.amazon.com/Trizact-5000-Gri ... B00LIXEWXO