First of all I am very pleased - and relieved - to mention that the panels are back in one piece and together.

Then just a couple of comments about the failure and the hide glue ...

The reason for the failure was that the join was glue-starved. As simple as that. Well, almost.

The reason for the join being glue starved was not because I used too little glue, and not because of the type of glue, but because I over-tightened the clamps.

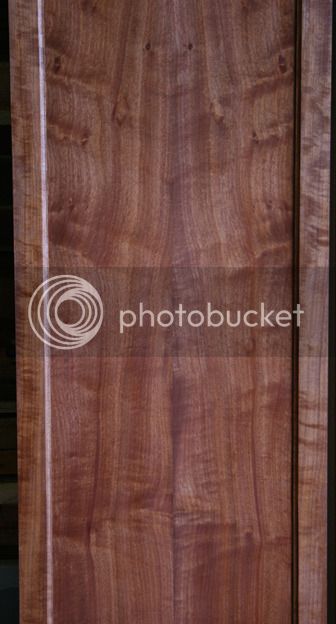

The over-tightening was due to the spring joint being too wide. What is a good- and what is a bad spring joint? Well, a good joint is one that may be closed with hand pressure, and a bad one is one that requires help to do so. In the case of the one panel, I got it right. In the case of the failed panel, clearly I did not. I could see light through the centre when I inspected the join, and immediately I knew this was the cause. Pulling the join together with a clamp just disguised the issue since all the tension was at the centre (where the join failed), and the force squeezed the glue out ...... no glue + tension = open up.

A second question is "why spring at all". Some like to do this and others argue that it is not necessary, that glue is tougher than wood. In my book, it is important to ensure that the ends of a panel contact each other. If there is any curvature to mating sides (and often this is difficult to see - which is the point), extra clamping at the ends creates two tension sections .. where as the spring joint only creates one tension point. But the spring must be almost imperceptible, as in the photo I posted.

A third issue is the choice of Titebond hide glue. Well hide glue rocks ... but Titebond? I have had a number of emails warning me about its use, that it is unreliable, etc. My experience with it is not long - about two years. In that time I cannot recall a failure. It needs to be pointed out that the mortice-and-tenon joints were solid. There was no failure there.

I must admit that I have avoided going to the trouble of preparing the stuff myself since I am lazy. The issue is that I get into the workshop on weekends only, and making up a fresh batch of glue each time, keeping it warm, etc .. well, it does not thrill me. Anyone have a way of circumventing this?

So back to the repair.

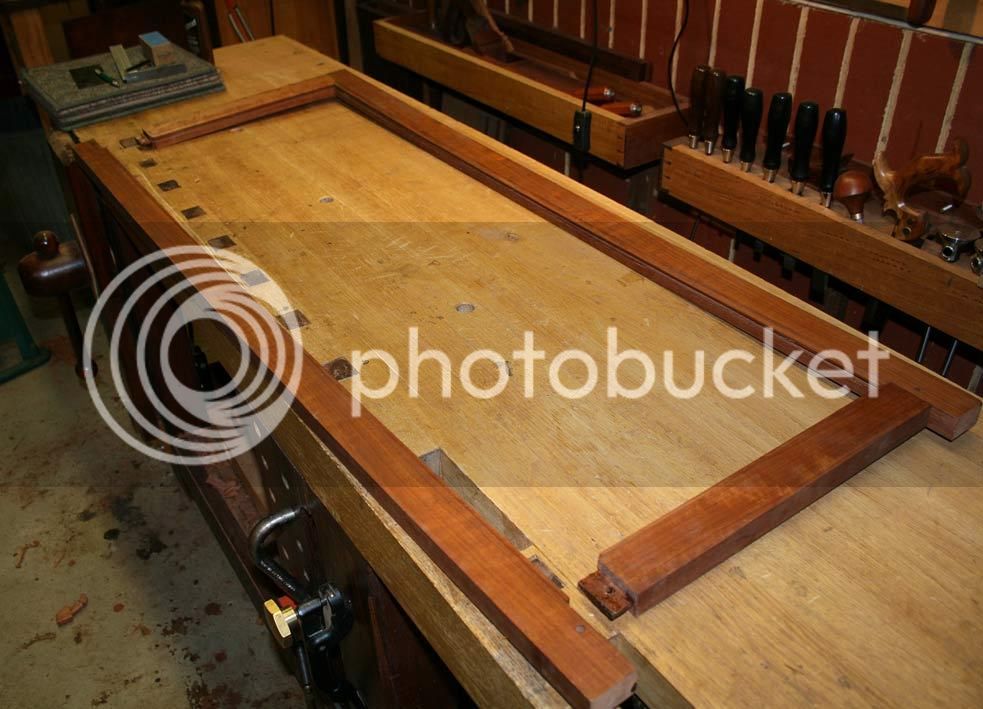

It the face needed a minimal amount of scraping to level the joint ...

... before I called it good and re-glued and pinned the panel inside the frame.

The repaired panel is on the left ...

Reinforcing strips were added to the rear - I had planned to do this anyway to beef up the thin panels. They will not be seen (on the inside) but will offer a little more reliability ..

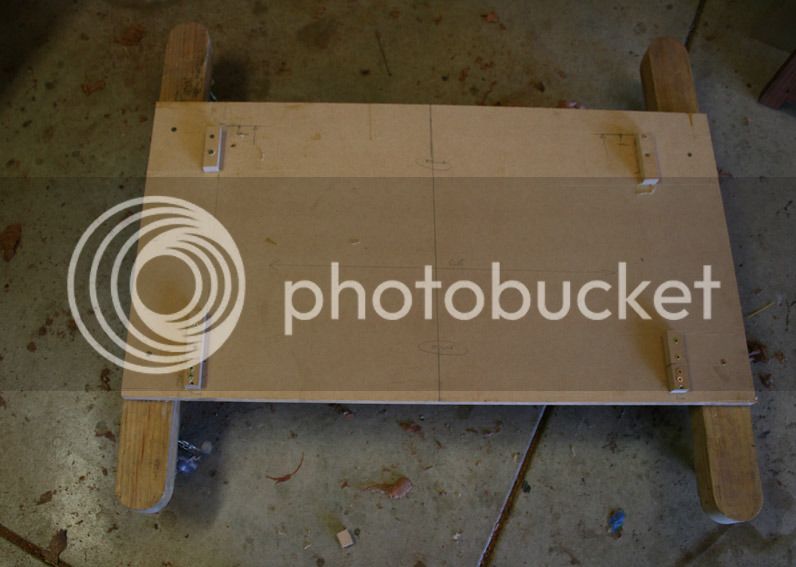

Some may be interested in the supports I built to aid accuracy in dimension and to keep everything square. The first was the base, which also will enable the chest to be moved around later ..

The other clamps across the top ..

So now we are back to clamping all on the jigs, with an added section of MDF clamped to the rear. The plumb bob ensures that vertical and centre is created, and may be returned to at any time ...

Once this is done, the inside perimeter can be traced onto the MDF. The MBF is moved to the bench, where the drawer dividers are drawn in. This is to act as a template.

A line is drawn down the centre of the cabinet template, and the dimensions first marked on this centre line ...

They are then transferred to each side ..

Here is the template back supporting the chest sides ...

I moved it to the other side and it was reassuring that there was about 1mm difference in the marked outline.

Now the intention was not to use these marks as the template, but rather to create a template from them. To do this the MDF outline was sawn down the centre, and then the curved side band sawn out, with a little cleaning up done with a small block plane.

Measurements are marked both sides ..

... and then transferred to each side of one board (only) ..

The panels are clamped together and the markings transferred from one board to the other ..

Once one side is match, the boards are rotated to complete the other matching edges ...

Now we can move on to marking out angled sliding dovetails and build the draw dividers.

Regards from Perth

Derek