Part 2 - Making the stand

Having worked out the size of machine base to be accommodated, I would start by cutting the rear piece to length (cut it slightly oversize at this stage), then follow it up with cutting the basic parts for the sides and lastly a front section where the feet will later mount. You can lay it all out on the floor of the workshop. Then grab something to drink and ponder and admire your work. By this stage, you will probably start to get a better understanding of how it all fits together.

(10). This shows the top inside looking towards the rear all bolted together temporarily for welding, bolts will then be removed

(11). And this one shows the top inside looking towards the front of the stand all bolted together temporarily. Note the front part of the stand has been raised up by 15mm to allow the lift bar to hook into the front of the stand when finished.

You will probably start to see that the front has two pieces of angle, one is used to close the rectangle or square central area, the other to form the front support, sitting a little higher up than the rest of the base.

Now when you look at the next two photographs, you should get a much better idea of how simple it is

(12). Rear underside before welding here:

(13). And front underside before welding here:

Don't worry too much about the additional parts for the front as I will cover this in more detail. Also don't worry about small gaps between parts as they will be filled up when welded, its not fine cabinetmaking here.

(14). To join the side "L" section to the back "L" section at 90 degrees and keep the area flat, you need to cut a square section out of the bottom of the "L" to fit into the corner as shown below (Red Arrow). If you are finding this hard to visualise, refer to picture (12) above where the top right shows the finished part bolted to the rear section in the direction of the Red Arrow. The cut out shown by the yellow arrow was only needed on my bandsaw base to clear the door and allow it to open. You also need to grind a "V" shape chamfer the two part meet on the underside at approximately 60 degrees (30 degrees per side). you need to create a "V" shape wherever two surfaces join or butt together flat. If they join at 90 degrees, then they are fine for welding without this feature (I hope this is all making sense). You need to cut four areas like this in the centre of the frame. The photographs show two rectangular plates bolted to the Mini Max S45 bandsaw frame, but you could use smaller triangular plates just as effectively as I have in the Sedgwick frame in picture (4) on page 1.

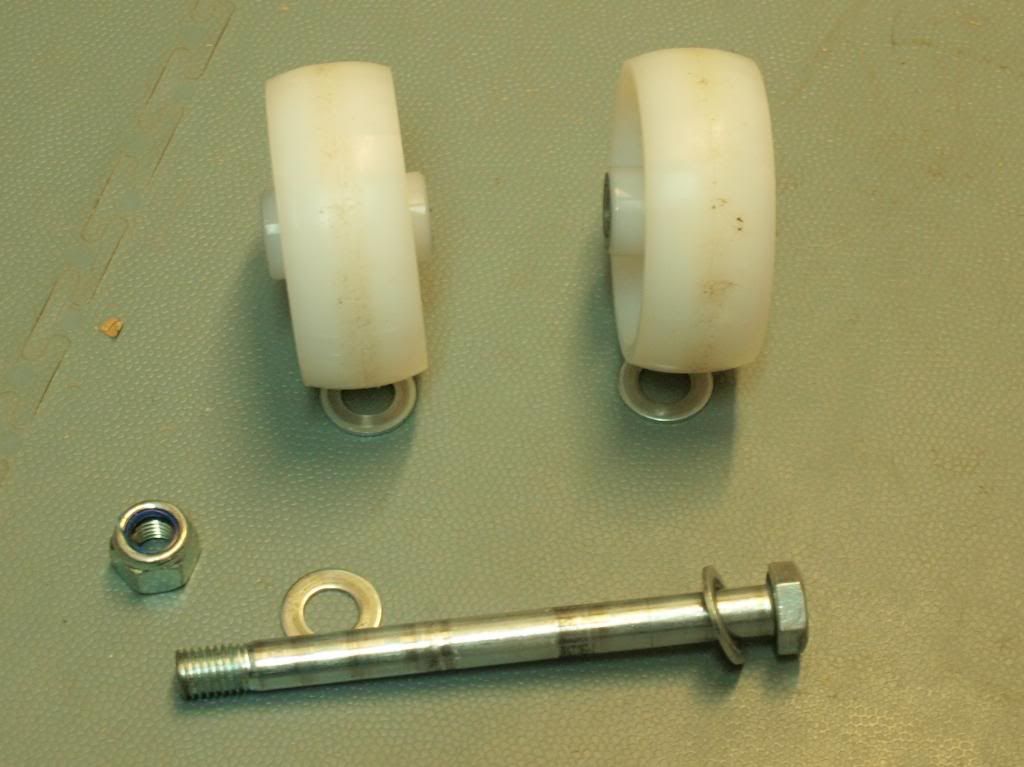

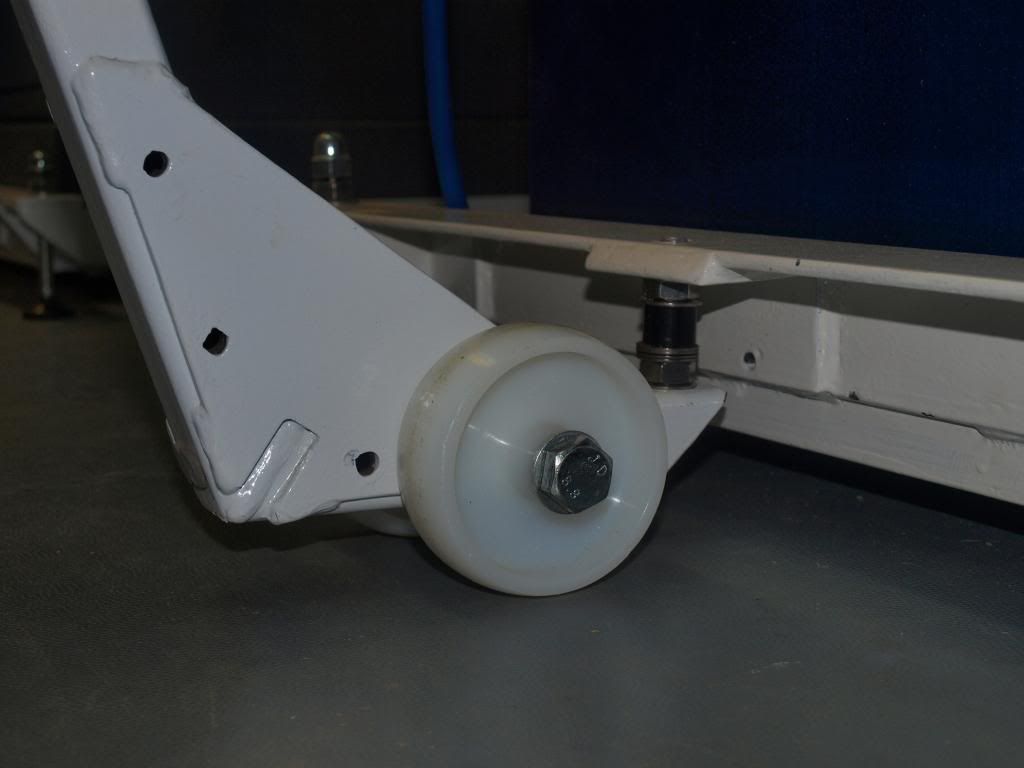

(15). Axles - The arrangement for the axles is the same for all the stand variations. You can shorten or lengthen the rear wheel outriggers to suit your particular machine / requirement. To keep it compact, you can shorten these axles even further than the one already shown. Before you start, I recommend you purchase the bolts that are used for axles. For the 100mm Nylon wheels I purchased, I needed a 10mm axle. In this arrangement, you can use two M10 bolts, zinc plated or if you are feeling particularly flush, Stainless Steel. It is important they are bolts (partially threaded) and not machine screws (fully threaded). The longer bolts I used were 170mm long, but you can tailor the length as I have said to suit you particular needs. In addition to the two bolts, you will also need 8 off plain M10 washers, 2 off plain M10 nuts and 2 off Nyloc M10 nuts. The axle arrangement is shown in the picture below. When constructing the frame, you position the brackets to suit the wheel width in the centre axle area, with the thread being used to adjust the amount of float allowed for the wheel. As the frame wheels are not constantly turning, you don't need expensive wheels with bearings. A washer is fitter either side of the wheel and between the frame and each nut.

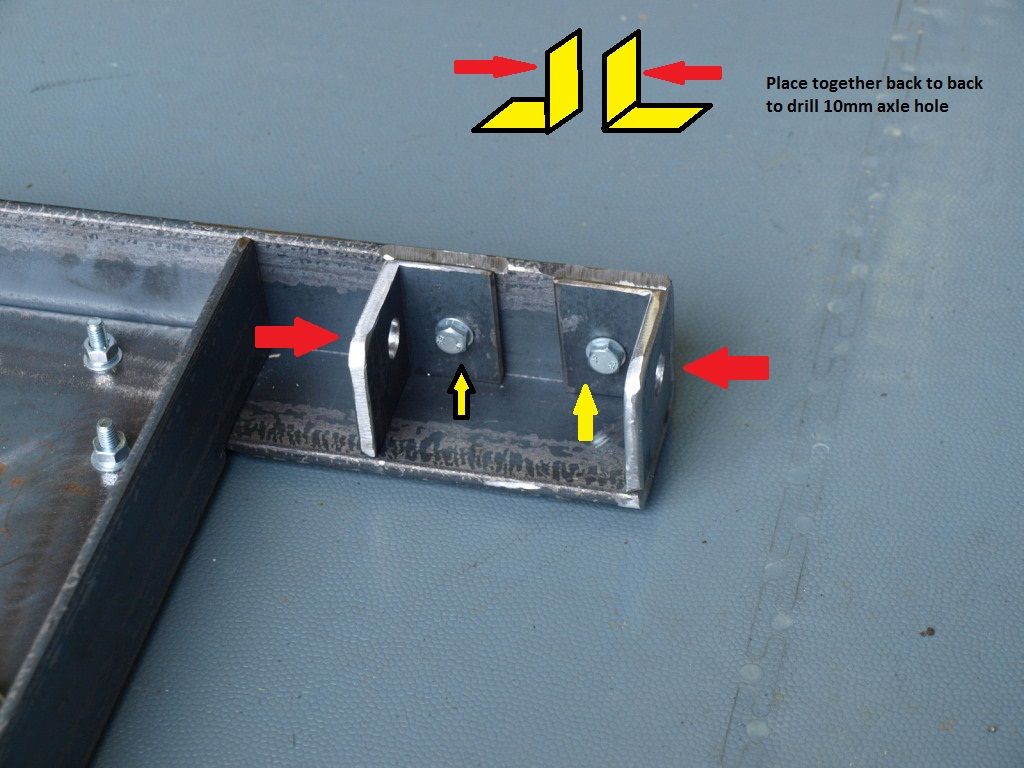

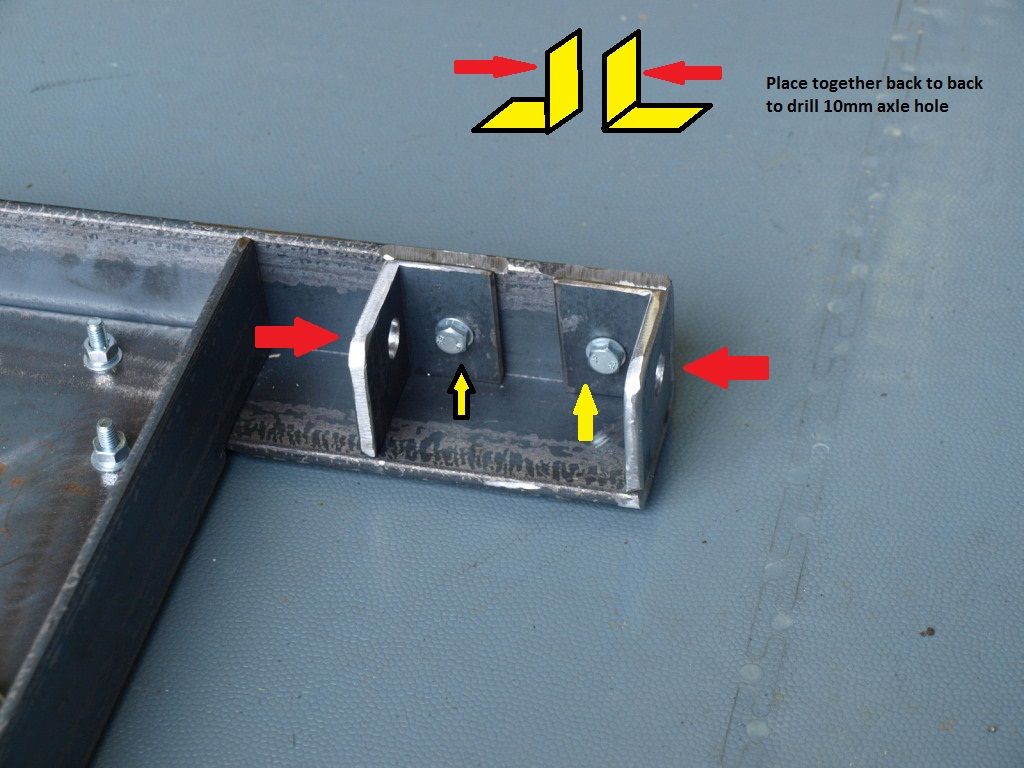

(16). Cut two small "L" shape sections similar to those shown from a piece of angle. Place them back to back to for a "T" shape as shown in the photograph and mark and drill a 10mm hole(shown by Red Arrows) through them both at the same time to ensure the axles are in line, remember to clamp these when drilling them. Temporarily fit them to the frame and assemble the axle to get the best adjustment. Clamp them in place, remove the axle and drill a 6mm hole through the axle support and frame (shown by Yellow Arrows). You now need to prepare these for welding. For the inner axle support, you need to grind the areas of the bracket and frame shown to approx 60 degrees to allow a good weld to be formed. For the outer bracket, you need the same are plus the outer section as shown below. I recommend bolting these to another piece of angle whilst grinding them down. This only takes a few minutes per bracket to complete this part of the job. Repeat the whole process for the other side.

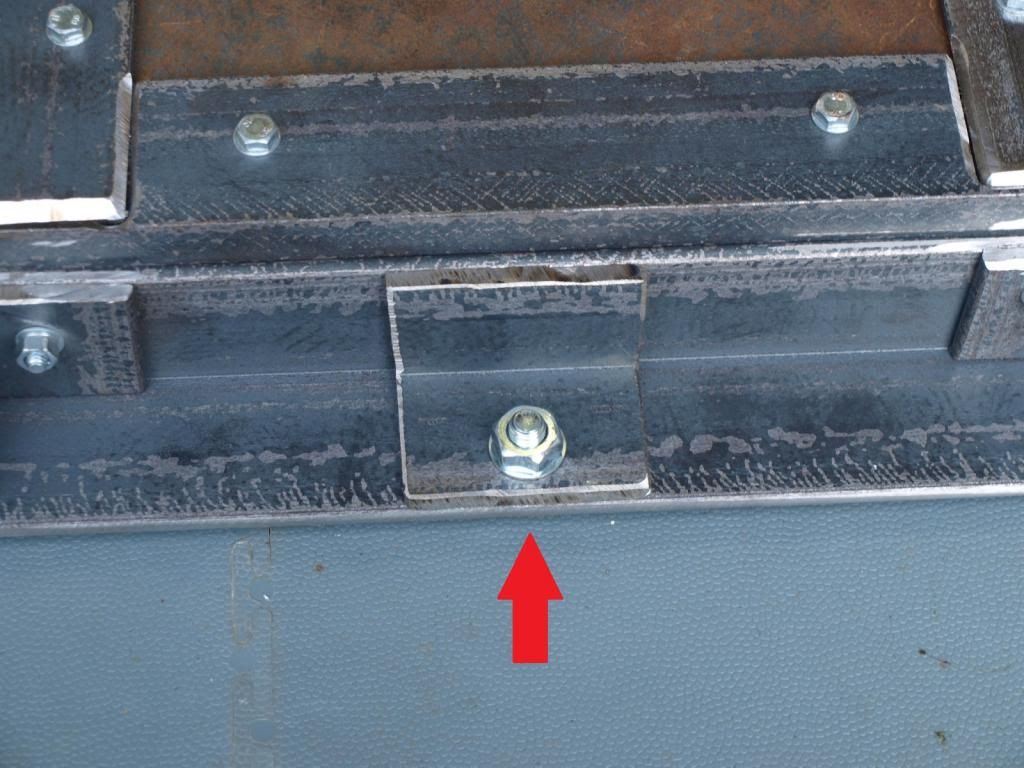

(17). Front Support: This photograph shows the underside of the front support section of the frame where the adjustable feed are fitted. The next two photographs show the detail of this part.

(18). At the extreme right hand side of the frame there is a triangular section fitted to give some strength at the foot mounting. A 10mm hole is also drilled through this and a bolt temporarily holds the two parts together. A 10mm UNPLATED nut has been fitted here and the nut will be tack welded to the frame to provide a fixing for the adjustable foot to screw into. On the left hand side of this photograph is another triangular section used to strengthen the section where it attaches to the frame. A 6mm bolt hold this onto the front "L" section as well as the central section of the frame. Again, this bolt is removed once welded.

(19). The next photograph shows the end prep for welding, with a 30 degree chamfer added to each part. Repeat the whole process for the other side.

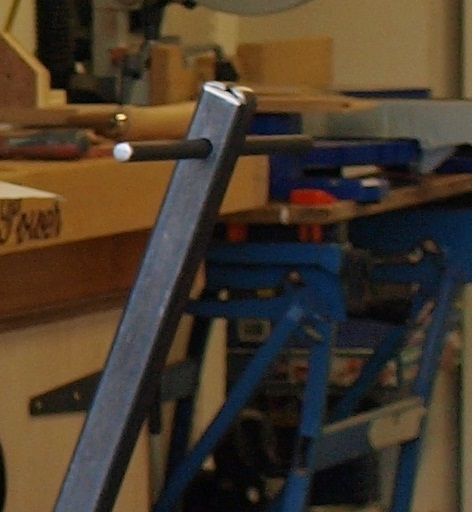

(20). The last part of the frame that you need to make is the lifting point in the middle at the front. I doubled up on thickness here and added another section underneath. This can be clamped to the main part and a 10mm hole drilled and temporarily bolted together for welding (see Red Arrow). When the bolt is removed, this becomes the hole for the lift bar to engage in - see next two photograph below.

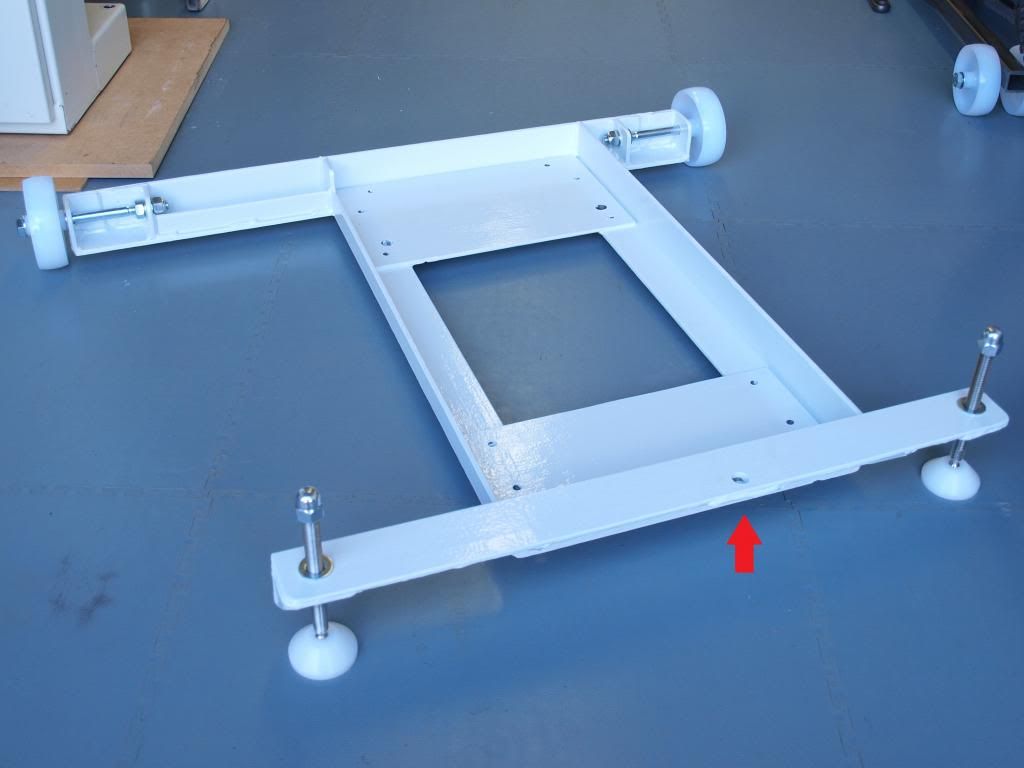

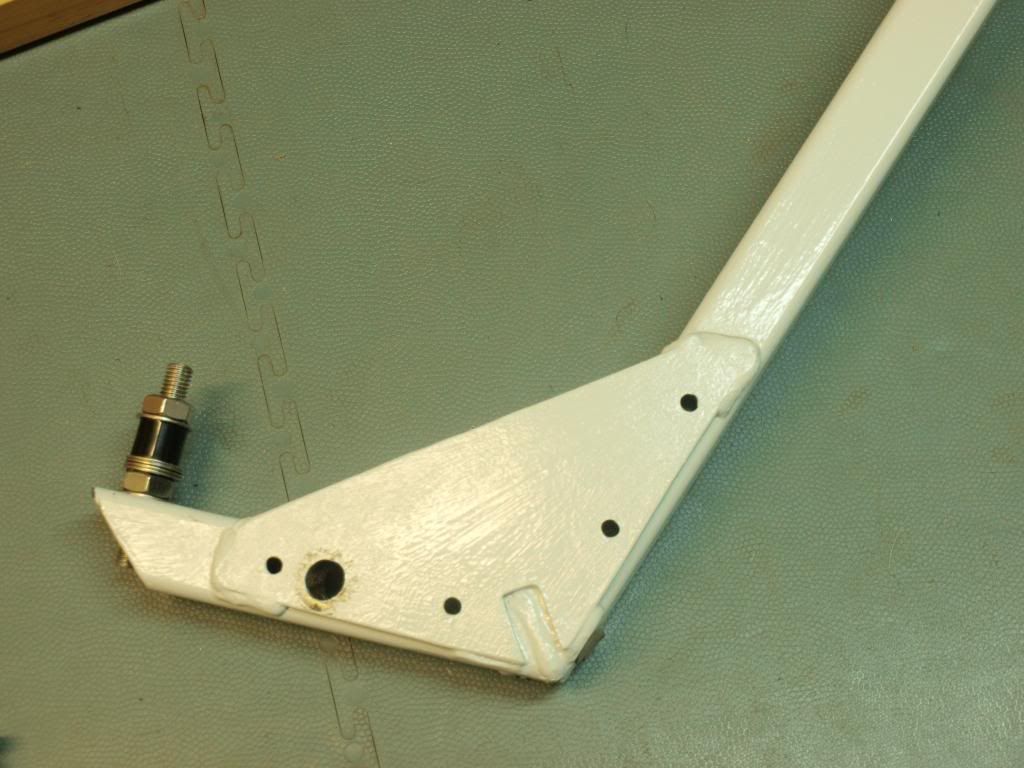

(21). And finished and painted after welding:

(22). You can now take the frame to your local fabricator for welding or do it yourself. Once welded, all the bolts are removed leaving only the two M10 nuts welded to the bottom of the frame (shown in photo 18). Now you can drill the mounting holes for the machine, In my case I had to drill four 12mm holes. Then I added a couple of coats of paint, fitted the wheels and axles along with two adjustable M10 feet (if you search the internet for suppliers you will get a number of companies who supply these sort of parts).

The machine can now be fitted to the base.

Almost finished, next instalment will cover making the lift bar.