I chose to finish this guitar with Tru-Oil in the end, and boy is it a nice finish. Just rub it on with some paper towel and leave it 24 hours and it looks spectacular. It brings out even the most subtle 3D grain:

From another angle:

The alder on the back took on a lovely rich warm tone, and the grain is quite fascinating. Here the "itteh bitteh kitteh inspection commiteh" is doing some quality control:

Treatment of the cutaway to assist high fret access:

Rear of the same - I had to carve away a lot here, the cutaway really should have been bigger!

From another angle:

The alder on the back took on a lovely rich warm tone, and the grain is quite fascinating. Here the "itteh bitteh kitteh inspection commiteh" is doing some quality control:

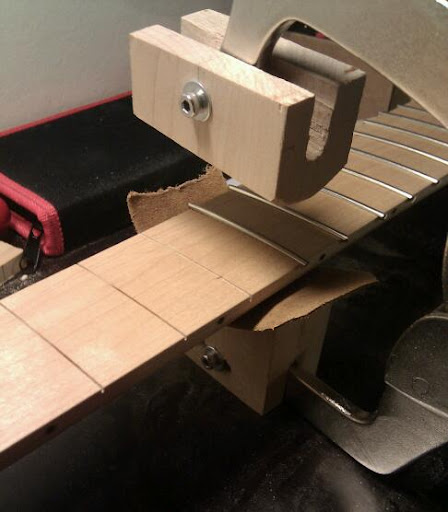

Treatment of the cutaway to assist high fret access:

Rear of the same - I had to carve away a lot here, the cutaway really should have been bigger!