kirkpoore1

Established Member

jimi43":2y1h6p4o said:...

...

The blades I have been using on version one....

...are bandsaw off-cuts kindly given to me by Ian at Tuffsaws....(thank you so much Ian!)....and I had a large number of options to try...including thin kerf meat and fish ones of huge proportions.

In testing and comparison with Douglas' Gramercy ones, I have come to the conclusion that they are all too aggressive...including the high TPI ones...and this appears to be down to the tooth profile and geometry.

The Gramercy ones, although courser TPI...were easy to start and run....and had a completely different profile.

So...conclusion...yes you can use bandsaw blade offcuts and indeed...these might be suitable for larger, heavier framesaws...but for bowsaws and delicate work...like tenons and dovetails...I feel the correct blades are the only option. Sadly, these are few and far between and inherently more expensive.

More tests will be done on these options.

Cheers

Jimi

Jimi:

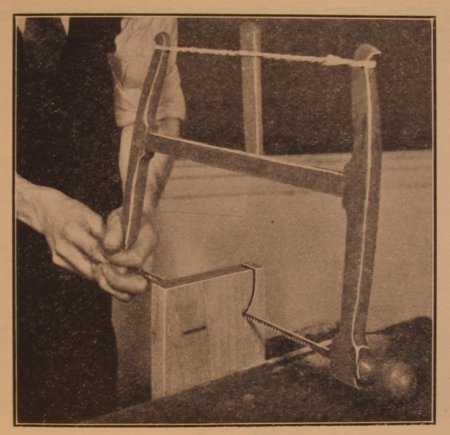

First, that's a very nice looking saw. Is there a functional reason you have different knobs on either end, or does it just make it easier to find the right end to cut from?

As for bandsaw blades, I'm glad you've been able to experiment. I use my bowsaw only for cutting curves and for inside cuts, all in materials that are medium to thin (3/4" or less). I've found that unless you use a fairly fine blade (more than 12 teeth per inch), the saw works very roughly in even 3/4" material. This would match your results. However, the 18 tpi blade I usually use cuts pretty well. I'm not expecting finish quality on these cuts, mostly I want to get where a spokeshave or even sanding can quickly get things done.

For tenons, I pretty much stick with my tenon saw. I do use the bowsaw to cut the bottoms out of the dovetail waste, but not the sides. Really, I built the bowsaw to replace the junky coping saws I had before, and it does that very well. To use it to cut thicker stock or long straight lines, I'd probably follow your lead and look for a true bowsaw blade. I imagine it would be possible to refile a bandsaw blade to a different profile, too.

Kirk