You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bobbin sander

- Thread starter Noggsy

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Thanks for the info on the Delta sleeves guys, I'll have a trawl around.

I have thought of another way to go, rather than buy a new machine I thought of getting the spindle bit and rubber inserts from a well known machine like a Jet and modifying it to fit the delta, that way I'll have a UK supply of sleeves.

It should only be a matter of turning up the Delta thread from the spindle of the Jet machine.

I have to say the Delta is such a quite machine, therefore I'd be reluctant to part with it.

Can anyone see any pitfalls?

I have thought of another way to go, rather than buy a new machine I thought of getting the spindle bit and rubber inserts from a well known machine like a Jet and modifying it to fit the delta, that way I'll have a UK supply of sleeves.

It should only be a matter of turning up the Delta thread from the spindle of the Jet machine.

I have to say the Delta is such a quite machine, therefore I'd be reluctant to part with it.

Can anyone see any pitfalls?

Mike Wingate

Established Member

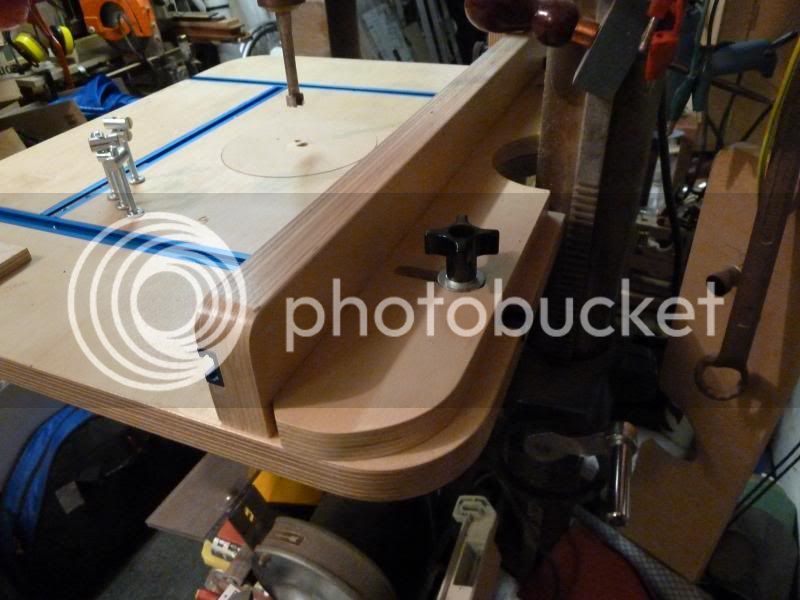

The fence is made from 4 hpieces of Baltic birch ply. The vertical fence is laminated for thickness and sandwiches the blue t track. Two hand wheel/knobs lock the fence onto the 2 t tracks on the table, they ride in slots to give an angled fence. The two stops on the vertical fence run in the fence t track and do come in useful.

SteveW1000

Established Member

I've also got a Delta don't think that the spindle unscrews its more a case of exchanging the rubber sleeve to a different size. I don't use the smaller sizes much and got Carroll to drill two of their spindle moulder drums to fit, 2" and 3" which allow me to use strips of abrasive paper rather than sleeves. Don't know if they will still do this I had to wait for them to reset the machines at the end of a production run.

Steve

Steve

SteveW1000":uqc6e67w said:I've also got a Delta don't think that the spindle unscrews its more a case of exchanging the rubber sleeve to a different size. I don't use the smaller sizes much and got Carroll to drill two of their spindle moulder drums to fit, 2" and 3" which allow me to use strips of abrasive paper rather than sleeves. Don't know if they will still do this I had to wait for them to reset the machines at the end of a production run.

Steve

Steve

Mine has an extended bolt that goes down through the rubber and screws into the machine, thats the bit I was going to retrofit to the Jet rubbers. Its got to be worth a try, or it's forking out cica £350.00 to get a comparable machine. A New Year project I think.

Mike Wingate":2a46epgv said:The fence is made from 4 hpieces of Baltic birch ply. The vertical fence is laminated for thickness and sandwiches the blue t track. Two hand wheel/knobs lock the fence onto the 2 t tracks on the table, they ride in slots to give an angled fence. The two stops on the vertical fence run in the fence t track and do come in useful.

I think that makes sense now

the fence is L shaped yes ?

sorry to keep jumping on this thread , but i really like the design and have an need for it soon

Steve

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£49.91

£58.33

Mefape Mortise and Tenon Jig Tools for Woodworking Routers, Tenon Cutter, Manual Mortising Machine, Invisible Slotting Machine Jig Stand, 3-Axis Guide Rail for Adjust Trimming Length and Width

wangshijuntianjinhongyuegongyipin

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

Mike Wingate

Established Member

Mike Wingate

Established Member

whiskywill

Established Member

Green":1d3t2v8e said:I even trust it enough to have used it to thickness down the headstock on a finished guitar.

I'd be interested to know how you held the guitar to ensure it stayed at the correct angle. Was it before you had cut out the head profile?

I have just finished an Irish Bouzouki and, stupidly, trial fitted the machine heads upside down. So the plan is to thin down the headstock and fit a back veneer to cover the screw holes.

custard

Established Member

I've got a Dakota/Triton/Sceppach bobbin sander. It's okay for smaller and lighter stuff but the table is pretty small. For bigger jobs I use a bobbin sander in a spindle moulder, that gives a much bigger table but it also gives speeds that are a bit too high for delicate material removal. I frequently make router/spindle templates for chair/table legs and curved furniture components, and a good big bobbin sander would be high on my shopping list.

I'd stay well away from drill press bobbin sanders unless it's for very light use only. The bearings on a drill press aren't designed for lateral forces and given that most economy drill presses have run out problems to begin with you're just going to get progressively less and less accuracy in your drilling.

I'd stay well away from drill press bobbin sanders unless it's for very light use only. The bearings on a drill press aren't designed for lateral forces and given that most economy drill presses have run out problems to begin with you're just going to get progressively less and less accuracy in your drilling.

Green

Established Member

whiskywill":yq71dp96 said:Green":yq71dp96 said:I even trust it enough to have used it to thickness down the headstock on a finished guitar.

I'd be interested to know how you held the guitar to ensure it stayed at the correct angle. Was it before you had cut out the head profile?

I have just finished an Irish Bouzouki and, stupidly, trial fitted the machine heads upside down. So the plan is to thin down the headstock and fit a back veneer to cover the screw holes.

Yep it was pretty much at the finish sanded stage. I had to thin down the back of the head as the front had a thick veneer that I hadn't accounted for.

I just held it upside down against a temporary fence and fed it against the direction of cut. Any up and down movement wouldn't matter until I reached the volute so I just let it ride on the table and made sure it was hard against the fence. The hardest bit was having to do all this on the floor as it is a neck through bass an was bumping against the ceiling of the garage.

whiskywill

Established Member

Green":z8cchjfv said:Yep it was pretty much at the finish sanded stage. I had to thin down the back of the head as the front had a thick veneer that I hadn't accounted for.

I just held it upside down against a temporary fence and fed it against the direction of cut. Any up and down movement wouldn't matter until I reached the volute so I just let it ride on the table and made sure it was hard against the fence. The hardest bit was having to do all this on the floor as it is a neck through bass an was bumping against the ceiling of the garage.Measure twice and all that...

I think I understand. Mine will be a bit more difficult as I want a radius at the top of the volute so will have to feed it in horizontally. I can see a jig making session coming.

Similar threads

- Replies

- 46

- Views

- 6K

- Replies

- 67

- Views

- 13K

- Replies

- 6

- Views

- 1K

- Replies

- 114

- Views

- 14K