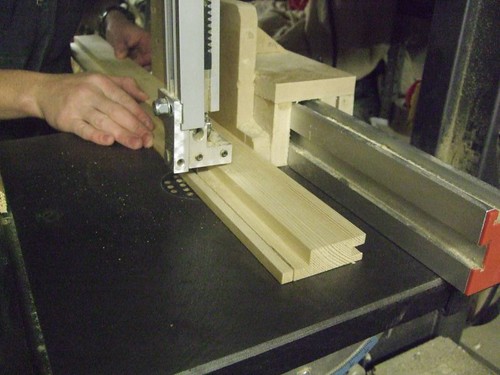

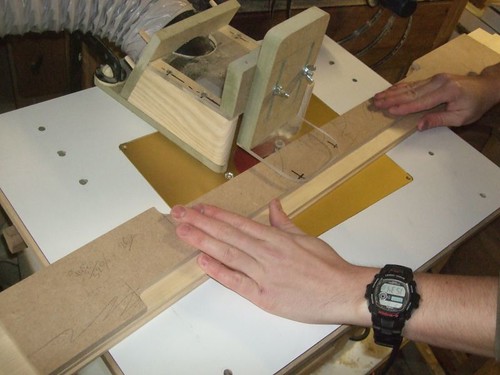

Another day of good progress today. With all the mortises cut, I was ready to tackle the tenons. Steve Maskery's router table jig is still my preferred method for ex. 1" timber. This should give you some idea of how it works, in case you haven't seen it before...

It was more awkward than usual, having to cut rails that were almost 1200mm long. They just about cleared the freezer and that sheet of OSB, though I had to run them over the cutter again when I realised I wasn't applying enough downward pressure to compensate for the overhanging length (in short, the tenons came out too thick). :roll:

I used a 25mm twin-flute straight cutter for this, which isn't bad... Except, it always leaves this 'fluffy' edges on the shoulders. It's nothing that can't be cleaned off with a sharp chisel but, I reckon I should one day invest in one of those cutters from Wealden, which are designed for this sort of work! :wink:

Once I'd cut all the rails to length, I realised I'd probably made too much of an allowance for waste... Oh well, these will come in handy when it comes to staining!

Haunches were all done on the bandsaw, using the mitre guide and then rip fence.

I was ready to assemble the frames and take a measurement for the shoulder lengths of the vertical rails (Muntins? Mullions? I forget!)... Until I realised (again!!) just how little room I have to work in. I managed to get it all done on the drive before the rain came over!

:wink:

Tenons were cut the same as before.

And then, I was ready to chop the mortises in the longer rails. Thankfully, both router table and mortiser were already set for these last two operations.

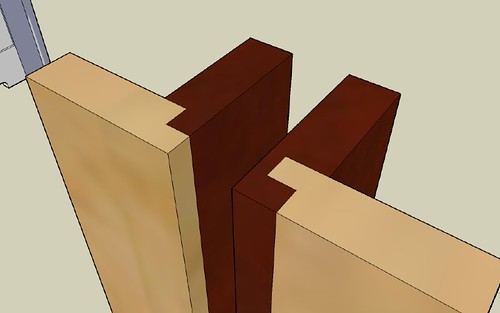

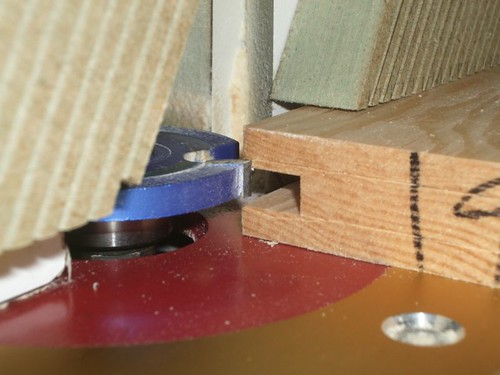

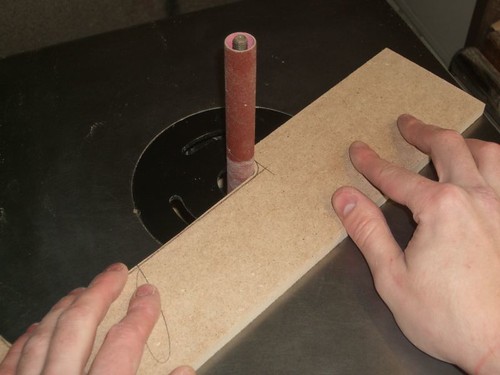

I still need to shape the bottom rails but, I decided to finish off the joint where each frame will meet at the corners. To start with I used one of the female components of the joint to set the cutter height.

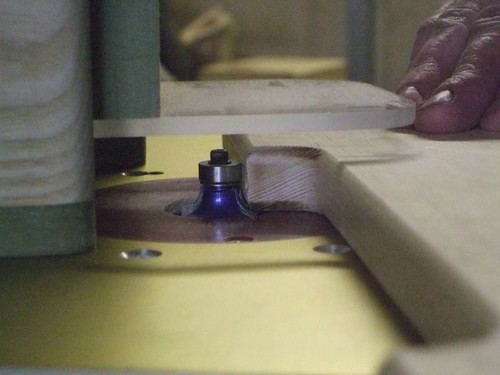

I completed the width of this cut in two passes, leaving the cutter set at about 12mm... :? In an ideal workshop (lots of space!), I'd have trimmed these boards by sticking them back through the thicknesser. In my small space though, it's a real PITA to have to go back to the planer thicknesser for a five-minute operation.

I knew I was chancing it with that depth of cut and it was all going fine, until the last one, where this happened... :shock:

Unfortunately, this will be visible on the outside. Looks like I'll have to machine up another one in the morning!

You can't really see it in this photo' but, the grain was a bit gnarly on this one length.

The rest were trimmed on the bandsaw.

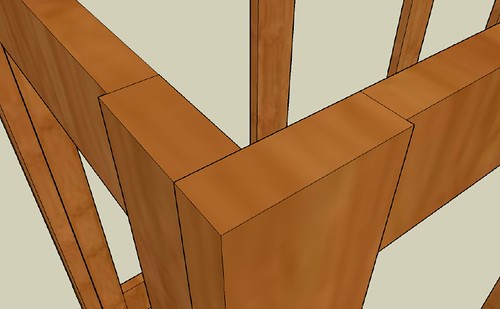

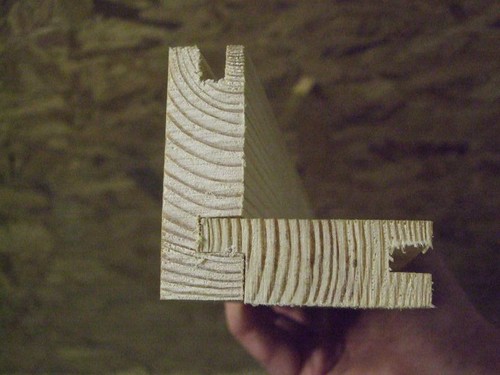

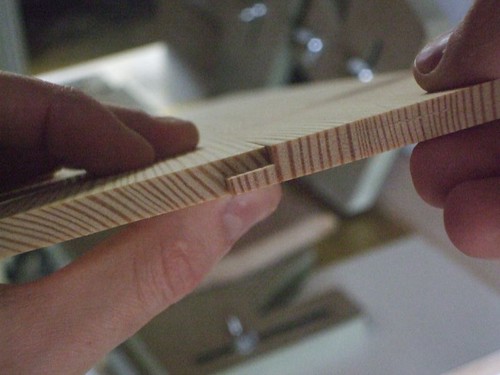

This is how the joint goes together, in case you weren't sure. I still need to trim the tongue a bit but, it's looking good.

I was hoping to crack on with the shaping in the morning but, it would be best to get this extra leg out of the way while some of my machines are still set up. I knew I should've planed up a spare one!! :roll: :wink: After that, I won't be starting on the panels until the weekend, due to college.