BradNaylor

Established Member

- Joined

- 17 Oct 2007

- Messages

- 2,311

- Reaction score

- 2

I owe a great debt to JonnyD for pointing me in the direction of using a router table for cutting the mitres on a beaded face frame in his recent thread. Previously I have used the table saw with questionable results and a hend-held router and shop-made jig which was OK but fiddly.

This method works like a dream and I can heartily recommend it. Thanks Jonny!

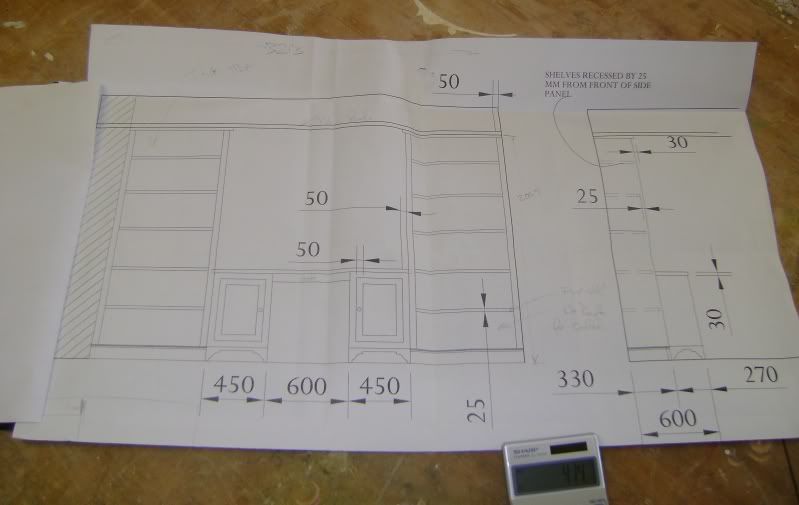

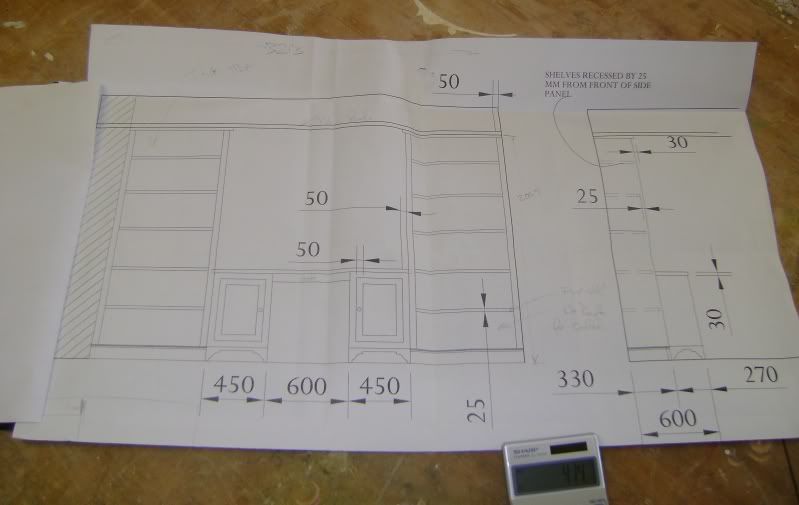

The job I am starting is a desk between two bookcases. Everything is painted MDF apart from the desk top which is solid oak. This is the drawing supplied by the client.

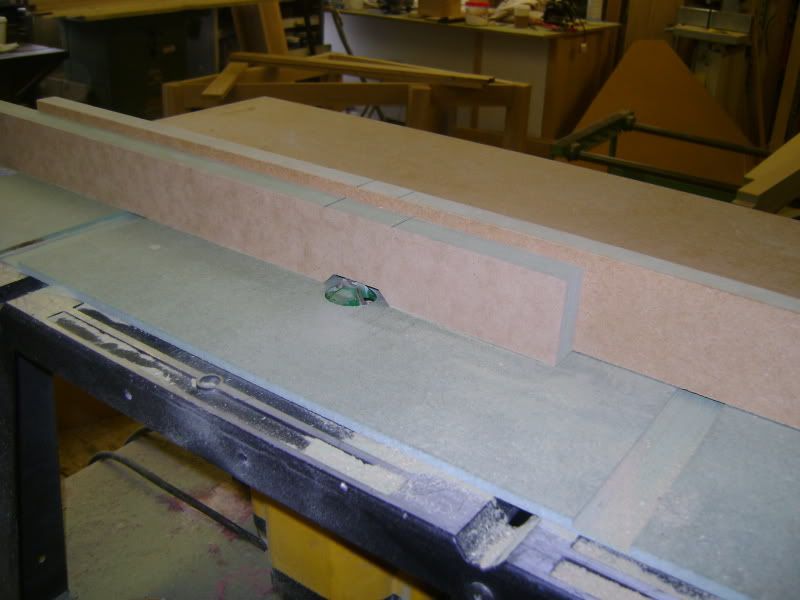

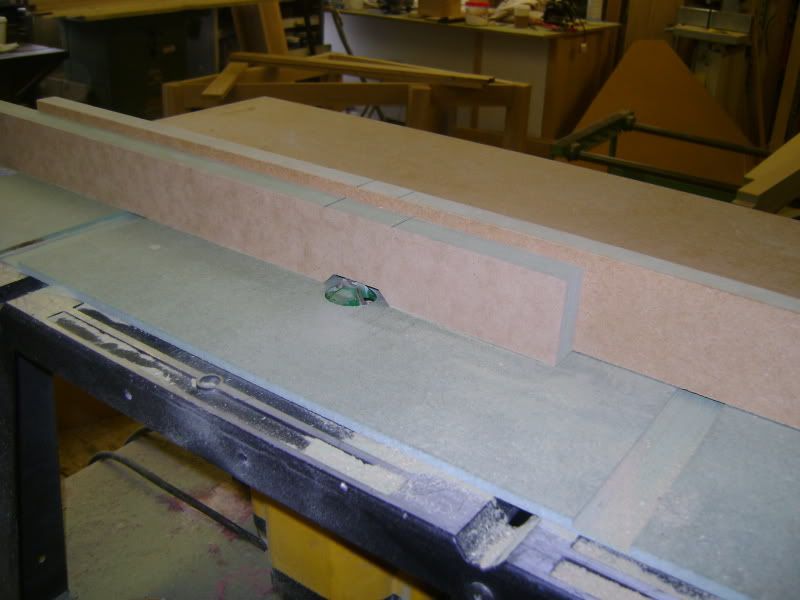

Firtst step is making the face frames for the desk pedestals and the bookcases.

I started by fixing a false bed to a router table with two parallel trenches (dadoes) cut into it to guide a sliding fence across the cutter at exactly 90 degrees. The photos are taken from the back of the router table for clarity.

The cutter is a flat bottomed 45 degree one from Trend's cheapo 'Trade' range. It is the only one with this profile I can find. The marking lines on the outside edge of the workpiece are lined up with the reference lines on the fence and the cut made in 3 passes.

I then cut Domino slots in the ends of the rails using the minimum width setting for a very tight fit

The ends of the rails are then mitred to fit the recesses machined in the stiles.

The fit is absolutely perfect!

Using a slightly wider setting and increasing the depth of cut I make the Domino slots in the stiles. It would be better to do this before routing the recesses but I didn't think!

I then marked the edges that required a bead routing on them

And machined away.

Two router tables makes a job like this a lot easier and quicker. Setting up takes a lot longer than the machining and it is great to be able simply to swap between one work-station and the other.

A little assembly...

And in the space of a couple of hours four face frames are in clamps.

While the glue sets I knock up the desk pedestals with Dominos and then fix the frames in place

The combination of the router table method and the Domino has cut the time taken to do this process in half for me. I am leaving that table set up ready for any future jobs.

Hope this is of interest and some help.

Cheers

Brad

This method works like a dream and I can heartily recommend it. Thanks Jonny!

The job I am starting is a desk between two bookcases. Everything is painted MDF apart from the desk top which is solid oak. This is the drawing supplied by the client.

Firtst step is making the face frames for the desk pedestals and the bookcases.

I started by fixing a false bed to a router table with two parallel trenches (dadoes) cut into it to guide a sliding fence across the cutter at exactly 90 degrees. The photos are taken from the back of the router table for clarity.

The cutter is a flat bottomed 45 degree one from Trend's cheapo 'Trade' range. It is the only one with this profile I can find. The marking lines on the outside edge of the workpiece are lined up with the reference lines on the fence and the cut made in 3 passes.

I then cut Domino slots in the ends of the rails using the minimum width setting for a very tight fit

The ends of the rails are then mitred to fit the recesses machined in the stiles.

The fit is absolutely perfect!

Using a slightly wider setting and increasing the depth of cut I make the Domino slots in the stiles. It would be better to do this before routing the recesses but I didn't think!

I then marked the edges that required a bead routing on them

And machined away.

Two router tables makes a job like this a lot easier and quicker. Setting up takes a lot longer than the machining and it is great to be able simply to swap between one work-station and the other.

A little assembly...

And in the space of a couple of hours four face frames are in clamps.

While the glue sets I knock up the desk pedestals with Dominos and then fix the frames in place

The combination of the router table method and the Domino has cut the time taken to do this process in half for me. I am leaving that table set up ready for any future jobs.

Hope this is of interest and some help.

Cheers

Brad