undergroundhunter

Established Member

Evening all,

I'm after a bit of help with my record BS400. I noticed today that the blade was no longer square to the table so set about squaring it up, upon closer inspection it appears that one side of the blade is perfectly square to the table while the other side is quite a bit out???? I'm really not sure what is going on here and the only explanation I can think of is the table is the issue. Anyone got any Ideas as to how this has happened and how can I correct it?

Square side

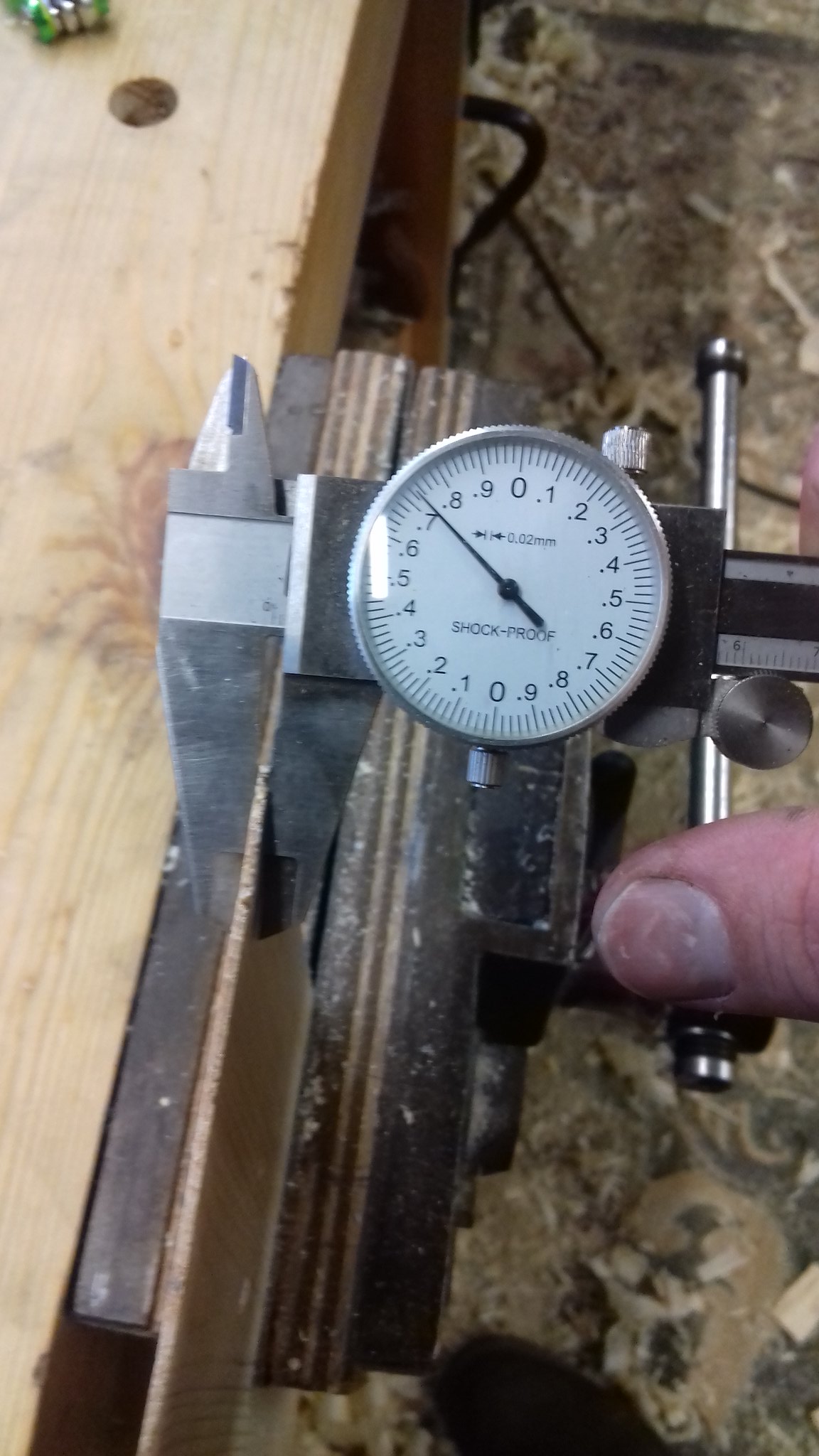

Non square side

Matt

I'm after a bit of help with my record BS400. I noticed today that the blade was no longer square to the table so set about squaring it up, upon closer inspection it appears that one side of the blade is perfectly square to the table while the other side is quite a bit out???? I'm really not sure what is going on here and the only explanation I can think of is the table is the issue. Anyone got any Ideas as to how this has happened and how can I correct it?

Square side

Non square side

Matt