TheTiddles

Established Member

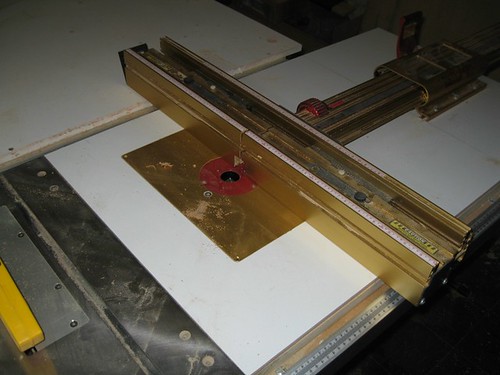

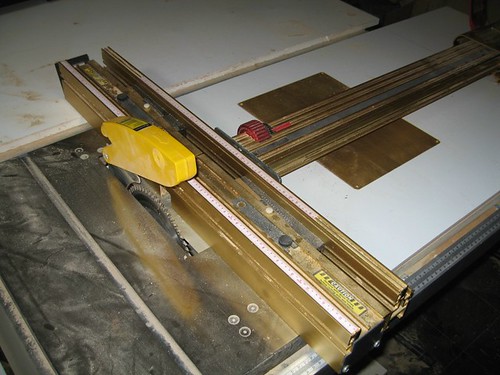

Has anyone built a unit to house their Axminster TS200 table saw? I have just bought one and during the first two hours of putting it together have decided that whilst it is a nice bit of kit it would be significantly better built into a rolling unit with maybe a router table using the same fence. Would anyone care to share their own designs? This will probably be the first project for this machine as it really needs it.

Further to that, what would be a suitable material to use? I have looked at 18mm birch ply at around £50/sheet though I would prefer to lip the edges with a decent wood so maybe a cheaper ply?

Aidan

Further to that, what would be a suitable material to use? I have looked at 18mm birch ply at around £50/sheet though I would prefer to lip the edges with a decent wood so maybe a cheaper ply?

Aidan