I was amazed at the build quality of this saw while assembling it today, like it was built in the 50s. Its heavy and the quality and sheer girth of it is in another league compared to the dewalt dw7485 its replacing (due to a hump in the top plate). And the top is flat, yay!

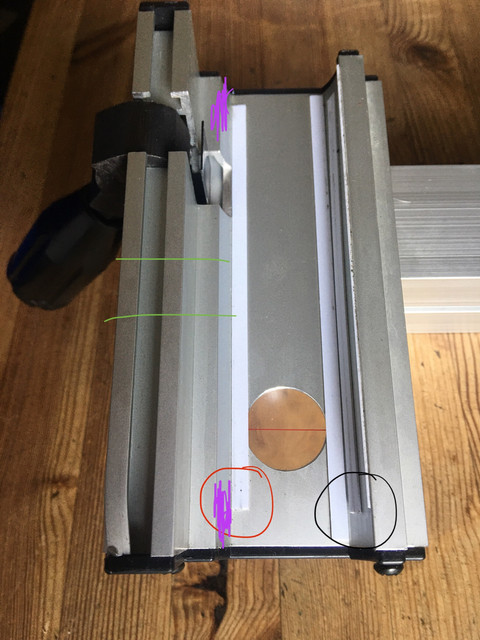

However the fence quality seems totally out of kilter with the rest of the machine. While the extrusions follow the pattern of heft and solidity the sliding carriage they ride is awful. Its wobbly, doesn’t slide smoothly on its rail, shifts angle when locking, and there seems to be no way to remove the carriage play without modifying it (its shimmed with plastic glides, that don’t). Is this behaviour normal?

What do people do to modify/improve the fence?

I didn’t buy the sliding table, but on seeing the way the fence operates I’m not entirely sure I will.

However the fence quality seems totally out of kilter with the rest of the machine. While the extrusions follow the pattern of heft and solidity the sliding carriage they ride is awful. Its wobbly, doesn’t slide smoothly on its rail, shifts angle when locking, and there seems to be no way to remove the carriage play without modifying it (its shimmed with plastic glides, that don’t). Is this behaviour normal?

What do people do to modify/improve the fence?

I didn’t buy the sliding table, but on seeing the way the fence operates I’m not entirely sure I will.