devonwoody

Established Member

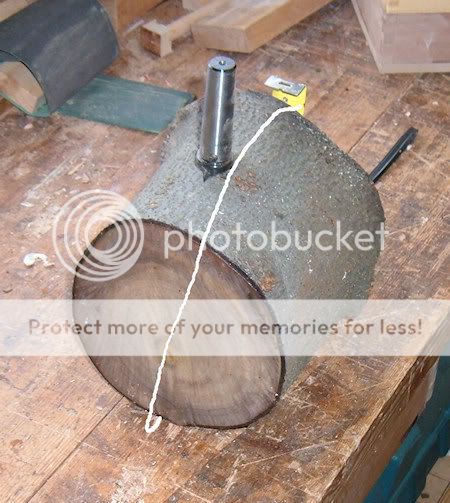

Trimmed this baytree log on the bandsaw and it finishes up around 6" square.

I have stuck a drive prong in temporary, this is where I want to drive .

Can a make a bowl or have I got to cut the log down the grain?

Any advice or plan of action gratefully received.

BTW I have now got my lathe bolted down.

I have stuck a drive prong in temporary, this is where I want to drive .

Can a make a bowl or have I got to cut the log down the grain?

Any advice or plan of action gratefully received.

BTW I have now got my lathe bolted down.